What is a refining machine

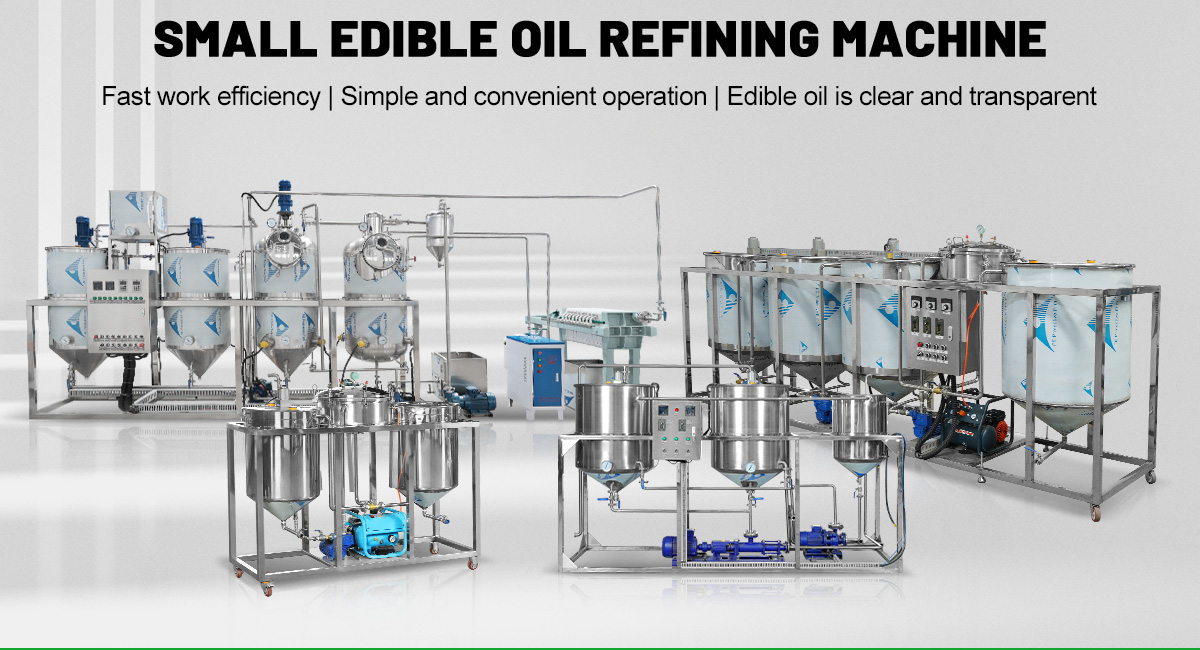

The edible oil refining machine is a small refining equipment used to refine crude oil, which can remove impurities in the edible oil, making the edible oil have a longer storage period, better color and odor, and greener and healthier.

What is the process flow of a refining machine

Main equipment: refining tank, decolorization tank, soap foot tank, deodorization tank (deacidification and deodorization tower), filter, evaporator, superheater, condenser, heat exchanger, vacuum system, thermal oil furnace, etc

The crude oil is pumped into the oil refining pot for degumming and neutralization operations. When the oil and soap are clearly separated and sink rapidly, stop stirring, let it stand, and then suck out the upper layer of clear oil to wash the tank with water.

The soap feet are emptied from the bottom tube and placed in the soap feet bucket. When the soap feet contain a lot of oil, the soap feet are stopped and pumped into the soap feet tank. The remaining oil in the refining tank is mixed into the next tank to continue. The clear oil and water transferred from the refining tank are washed and then taken to the decolorization tank for adsorption decolorization.

The decolorized oil is pumped into the gas separator at a constant flow rate through a pump, and the oil flow rate is regulated by a flow meter. In the gas separator, oil is sprayed out through multiple nozzles on the feed pipe, and a high vacuum is maintained in the gas separator to release a small amount of air that seeps into the oil.

Oil comes out of the gas separator, is pumped into the oil oil heat exchanger, and exchanges heat with the hot oil coming out of the deodorization tower. It then flows into the heat transfer oil heater for heating. The hot deodorized oil enters the combined deodorization tower from the heat transfer oil heater, where fatty acids and other relatively volatile odor substances are extracted using direct steam in the packing section, and then enters the plate section for deodorization and thermal decolorization.

When processing oil products with low acid value or low requirements for the acid value of finished oil, they can directly enter the plate section for deodorization and thermal decolorization without passing through the filling section. Deacidification and deodorization are operated under high temperature and high vacuum conditions. The oil after deacidification and deodorization is discharged from the combined deodorization tower, pumped into a heat exchanger for heat exchange with the oil to be deodorized, then enters a cooler, cooled by water, filtered through a fine filter, and stored in a finished oil storage tank.

The Relationship Between Refining Machines and Oil Presses

The relationship between refining machines and oil presses primarily manifests in their sequential integration within the edible oil production process. Oil presses handle primary oil extraction, while refining machines undertake subsequent quality enhancement. Together, they form a complete edible oil processing system.

- Division of Labor Between Primary Extraction and Deep Purification: As the initial stage of edible oil production, oil presses mechanically separate lipids from oilseeds through pressure (e.g., screw presses), yielding crude oil containing impurities, gums, and free fatty acids. Their core function is efficient lipid extraction, yet crude oil may retain phospholipids, pigments, and off-flavor compounds that directly impact the color, taste, and shelf life of edible oils.

- Refining units undertake the purification of crude oil through processes such as degumming, neutralization, decolorization, and deodorization to remove impurities and harmful components. For instance, degumming removes phospholipids to prevent oil oxidation; neutralization neutralizes free fatty acids to enhance stability; decolorization adsorbs pigments to improve color; and deodorization eliminates off-odors to enhance flavor. The final output meets national standards for finished oil, ensuring compliance with food safety requirements.

- Production Process Integration: The Complete Path from Crude Oil to Refined Products

- In edible oil production, oil presses and refining units form a continuous production line. Oilseeds (such as peanuts, soybeans, and rapeseed) first enter the oil press, where they undergo pressing or solvent extraction to yield crude oil. The crude oil is then transported to the refining unit, where it sequentially undergoes degumming, neutralization, decoloring, and deodorization processes, ultimately becoming finished oil ready for direct sale.

- Equipment Collaborative Optimization: Dual Enhancement of Efficiency and Quality

- The integrated design of oil presses and refining machines can significantly enhance production efficiency and product quality. For instance, large-scale peanut oil processing plants typically adopt integrated “oil press + refining machine” production lines. The oil press section incorporates pre-treatment equipment such as peanut shelling machines and vibrating cleaning screens to ensure seed cleanliness and reduce impurities in crude oil. The refining machine section integrates modules for degumming, neutralization, decoloring, and deodorization, enabling automated continuous production. This setup reduces labor costs while improving oil yield and product stability.

What is the effect of the refining machine

The refining machine produced by Fude Machinery can extract various types of edible oils, including coconut oil, sunflower seed oil, olive oil, rapeseed oil, peanut oil, soybean oil, corn germ oil, cottonseed oil, etc. The edible oil refining equipment can also decolorize the edible oil, such as blackening of rapeseed oil, reddish brown peanut oil, cloudy soybean oil, etc.

After treatment, the edible oil is clear and transparent. In addition to decolorization treatment, it can also deodorize the edible oil. Some edible oils have just been produced and have an odor or a strong odor, which affects the quality of the edible oil and does not meet the relevant requirements. After treatment by our company’s edible oil refining machine, the edible oil can be Remove the odor of cooking oil and make it fragrant.

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business