Small oil press equipment

Mini Oil Mill Machinery Advantages

The mini oil mill is a series of machines used to extract oil from various oil bearing seeds. They include: ground nuts, sesame, sunflower, cotton seed, castor seed and lin seeds, just to mention a few. With more technological advancements in the agricultural sector and inaccesibility of more developed large scale oil mills, many individuals have opted to set up a complete mini oil mill in their local places. Not only have these oil mills help generate income in rural areas but they have also helped to create numerous employment opportunities in the villages.

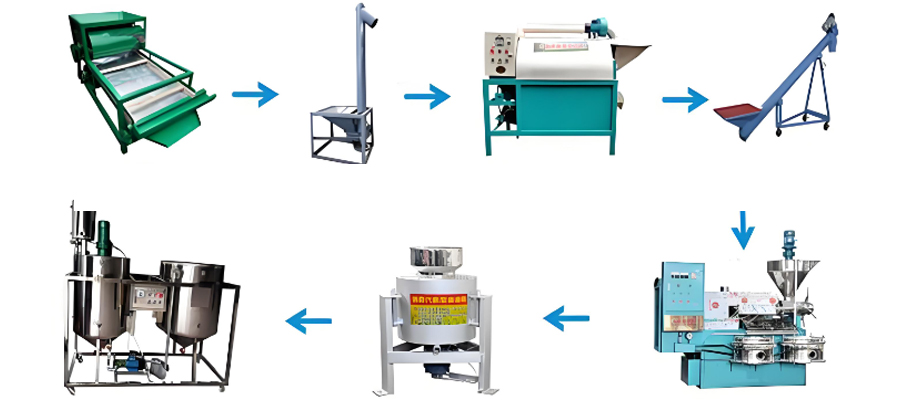

Owing to their simplicity and ease of handling, most of these mini oil mill machineries are manufactured idealy for small enterprenuers and village farmers as they offer small to medium scale oil extraction. Its worth noting that a complete mini oil mill has several component parts that makes it whole, each playing a different role. They include:

- Decorticator: used to remove oil seeds and kernels from their shellings.

- Heating kettle: it cooks the seeds/kernels obtained after the husks have been removed.

- Oil expeller: this is what crushes the oil seeds to obtain oil and oil cake.

- Filter press: removes unwanted impurities from the oil yielding a pure edible product.

- Boiler: it uses husks from the decorticator to produce heat required in the kettle.

- Neutralizer: it’s used to remove fatty acids from the oil seeds by introducing caustic soda to it.

Comprehensive functionality, addressing different user needs

Small oil presses are not only suitable for common oilseeds such as peanuts, soybeans, and sesame, but also for processing various raw materials such as walnut kernels, sesame seeds, tea seeds, and cottonseeds. Its versatility enables it to meet the needs of different users for oil products, such as extracting peanut oil, sesame oil, sesame oil, etc., and even making blended oils. This wide applicability makes it an ideal choice for households and small workshops, especially for users who wish to extract a variety of oils. You can choose a suitable oil press according to the different types of oil you press.

With the numerous advantages that come with mini oil mills, there is no doubt that its gaining popularity amongst small scale farmers who have chosen to engage themselves in this lucrative oil milling business. Some of the advantages of owning a mini oil mill machinery are as thus:

- It helps one realize full profits by eliminating the exploitative middlemen who will always want to link the farmer to the oil millers. It also cuts on expensive transportational costs as well as hefty taxes that one would have to pay to a centralised miller in order to get their oil seeds processed.

- Oil cake, a by-product during oil production, has helped many farmers practise mixed farming as its not only a highly nutritious animal feed but also helps to boost milk production in dairy animals.

- The mini oil mill machinery is easy to operate and maintain. This saves the farmer more time as well as resources that could be wasted while trying to catter for the same.

- These oil mills help to encourage rapid rural development since they facilitate wealth creation and open up employment opportunities for the villagers thus improving their living standards significantly.

- The technology used to craft these type mills is so simple that no hard training should be undertaken in order for one to master how they operate. Basically, training can take a maximum four days for one to completely learn how these mills operate.

- Just like large scale mills, the oil produced is of high quality with its filtration even giving it a more natural transparent appearance. The same for the oil cake produced.

If you plan to enter the oil processing industry, the wisest choice is to purchase a set of small oil pressing and processing machinery. Not only is it cost-effective, easy to operate, and has low operating and maintenance costs, but the high-quality products produced by Zhengzhou Fude Machinery will definitely give you a place in the market.

Related recommendations

-

Difference between hydraulic press and screw press

515Problem: Choosing between hydraulic and screw oil presses can be confusing. Agitation: Making the wrong choice wastes money and limits your production potential. Solution: Understand their core differences to select the best fit for your needs. ...

View details -

What is the use of dryer in agriculture

578Drying machines have broad application prospects and important value in agriculture.

View details -

What are the factors that affect the price of oil presses in 2024

853The factors that affect the price of oil presses are multifaceted, and together they determine the market price of oil presses. The following are some main influencing factors: Oil presses can be divided into two types according to their w...

View details -

How Do Oil Presses Work? A Guide for Your Business

189How is an oil press used to extract oil? Is there any profit from oil extraction? If you happen to have doubts about oil processing business, let's explore this topic together. So, how do oil presses work? An oil press is a machine that us...

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business