Small oil pressing production line

Small Oil Pressing & Refining

Our small oil pressing line consists of various equipments that work together to produce oil from oil rich seeds or nuts such as sunflower seeds, pea nut kernel, soy beans, cotton, sesame seeds and many others.

When the individual machines are linked to work together, the small oil processing line becomes autonomous. This brings great benefits to this mode of operation as opposed to more traditional oil processing machines.

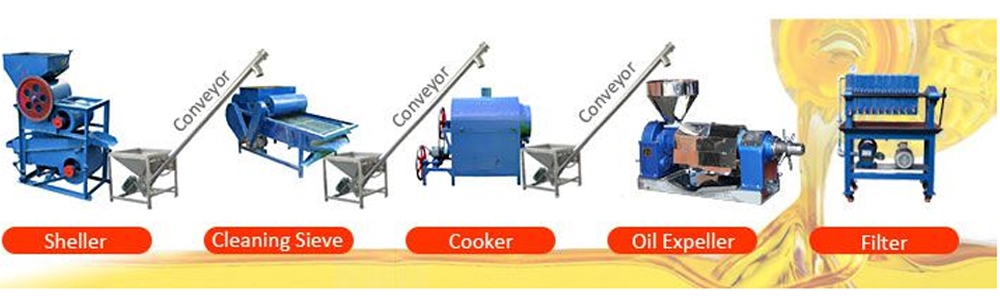

The small oil pressing line composition

- Cleaning sieve/screen

- Oil seed cooker/roaster

- Oil press/ oil extractor

- Oil filter

- Screw elevator/ conveyor

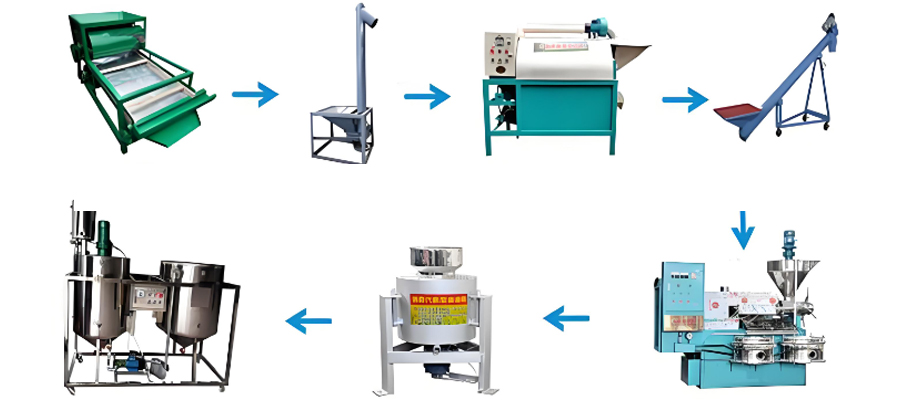

Operation of Small Oil Extraction Processing Line

- The oil rich seeds or nuts are first cleaned by passing them through the screening machine, to remove dust, rock particles, bad seeds and any other impurities in order to improve the overall quality of the end product cooking oil.

- The cleaned oil seeds or nuts that have gone through the screening machine, go to the screw elevator which passes the seeds through the oilseed cooking machine, that cooks the seeds. This cooking process is beneficial in increasing the overall oil output of the seeds compared to oil from uncooked seeds/ nuts. This cooking machine offers options to run on a variety of fuels depending on what is most cheaply available.

- The cooked seeds again rise through the screw elevator to the oil press machine, and are now ready for oil extraction. Oil is extracted when the seeds go through the oil press machine. The oil press machine can be an integrated oil press and filter machine that extracts oil and filters the oil off any impurity, or just a stand alone oil press which extracts the oil from the seeds and the oil can pass on to a separate filter machine.

- Oil filtering machine filters oil that has been extracted from an oil extraction machine/ oil press that is not integrated with a filter, to produce a cleaner cooking oil.

Operation video of small oil pressing unit

The working principle of a small oil press is to squeeze the oil through a spiral or hydraulic structure, separating the oil from the oil. Specifically, the oil is fed into the squeezing chamber, and as the squeezing screw rotates, the space gradually shrinks, generating pressure that pushes the oil out of the gaps in the squeezing cage, and the residue is pressed into a cake shape and discharged. Some equipment is also equipped with a temperature control system, which softens the oil by heating and improves the oil yield.

Advantages of Small Oil Presses

- Afford ability

Compared to large mills, the small oil pressing plant costs less to buy and install. This makes the small oil processing plant affordable and ideal for people who intend to start small scale cooking oil production.

- Less floor space requirements

The small oil pressing line occupies a significantly smaller floor space which becomes a huge saving on the small scale cooking oil producer’s side as he/ she doesn’t have to rent a bigger-usually more expensive work shop space.

- Reduced labor input

Zhengzhou Fude Machinery small oil processing line is semi autonomous, which means it only requires 2-3 workers compared to traditional oil processing machines which are very labor intensive. The reduced workers costs make a huge saving in terms of overall cooking oil production costs.

- Cheaper cooking oil

The new improved small oil processing line invented.

Related recommendations

-

What is a refining machine? How can oil quality be improved?

197You have successfully used an oil press to extract crude oil. But what is the next step to grow your business? The answer is refining. So, what is an oil refinery machine? It is a set of equipment that cleans and purifies crude vegetable oil. Thi...

View details -

Which oil crops is the screw press suitable for

460Screw oil press (usually also known as spiral oil press) is a mechanical equipment widely used in the processing of plant oil. It is suitable for pressing various oil crops, including but not limited to the following: ...

View details -

What is the application scope of hydraulic oil press

441Hydraulic oil press is a device specifically designed for extracting various vegetable oils

View details -

Extraction of Oil from Soya Beans

608The edible oil produced from soybeans is light, clean, and flavorful. This makes it more popular and loved by many people. Soybean oil is composed of 60% polyunsaturated fat and 24% monounsaturated fat, which combine to form a heart healthy oil....

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business