How to Start a Sunflower Oil Refining Business?

Sunflower seed oil holds a significant position in the global edible oil market due to its rich content of unsaturated fatty acids, vitamin E, and other nutrients, as well as its mild taste and high smoke point. Engaging in sunflower seed oil refining not only meets market demand for high-quality edible oils but also generates substantial economic benefits for enterprises.

Starting a sunflower oil refining business is an excellent way to add huge value to crude sunflower oil. Refining turns the dark, raw oil from a press into the clear, high-quality cooking oil that consumers demand. This process requires specific knowledge and equipment. We are Fude Machinery. As a factory-direct manufacturer of oil processing equipment, we help entrepreneurs around the world build profitable businesses. We will show you the exact steps and machinery you need to start your own successful sunflower oil refining business.

Table of Contents

- What is Sunflower Oil Refining, and Why Do It?

- What are the Main Steps in the Refining Process?

- How Do You Choose the Right Refining Equipment?

- Preparatory work before commencing the refining equipment business

- Trends in Refining Equipment Development

- Commencing Refining Machine Operations

What is Sunflower Oil Refining, and Why Do It?

Sunflower oil refining is the process of removing impurities from crude sunflower oil. The oil that comes directly from an oil press machine is called “crude oil.” This crude oil is not suitable for cooking. It contains things like gums (phospholipids), free fatty acids (FFAs), color pigments, and traces of smell. Refining cleans the oil and makes it stable, clear, and neutral in taste. The goal of a sunflower oil refining business is to produce what is known as RBD sunflower oil. RBD stands for Refined, Bleached, and Deodorized.

Why should you refine the oil? The simple answer is profit. Refined sunflower oil sells for a much higher price than crude oil. It has a longer shelf life, which is essential for retailers. Consumers prefer a clean, light-colored oil that does not interfere with the taste of their food. By investing in an oil refinery plant, you are transforming a basic commodity into a high-value finished product. This allows you to serve a much larger market, from local supermarkets to large food manufacturing companies.

What are the Main Steps in the Refining Process?

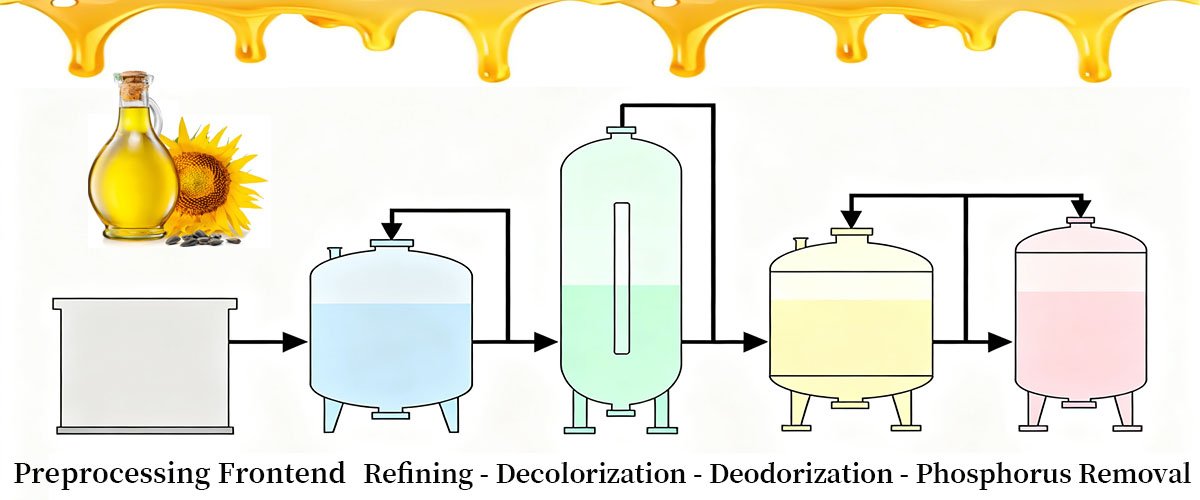

The process to produce RBD sunflower oil involves four main stages. These stages must be done in the correct order. They are: degumming, neutralization, bleaching, and deodorization. Each step targets and removes a specific type of impurity. All these processes take place in a series of connected vessels and machines that make up a complete oil refinery plant. Think of it as an assembly line for purifying oil. A well-designed plant from a trusted manufacturer like us ensures that each step is done efficiently, using the minimum amount of energy and consumables.

Understanding these four steps is the key to understanding the refining business. You are not just buying machines; you are buying a process. The quality of your final oil depends on how well each of these stages is performed. Let’s look at each step one by one to see what it does and why it is so important for creating high-quality refined sunflower oil.

Step 1: Degumming – Removing the Gums

The very first step is degumming. Gums, or phospholipids, are impurities that will burn during high-heat cooking and make the oil cloudy. To remove them, we simply mix the crude oil with a small amount of hot water or a weak acid. This makes the gums absorb water and become dense. We then use a centrifuge to spin the oil at high speed. The heavier, hydrated gums are separated and removed. This step is critical because if gums are not removed, they will interfere with all the later stages of refining.

Step 2: Neutralization – Removing Free Fatty Acids

After degumming, the oil still contains Free Fatty Acids (FFAs). These acids give the oil an unpleasant, sharp taste and cause it to go rancid quickly. In the neutralization step, we add a precise amount of a food-grade alkali solution, usually caustic soda. This solution reacts with the FFAs to form a substance called soapstock. Just like in the degumming stage, this soapstock is heavier than the oil. We use another centrifuge to separate and remove the soapstock, leaving behind neutral oil.

Step 3: Bleaching – Removing the Color

The neutral oil still has a yellowish or reddish color from natural pigments like carotenoids and chlorophyll. The bleaching step is designed to remove these colors and make the oil clear and bright. This is not chemical bleaching like with laundry. Instead, we mix the oil with a special, natural material called bleaching earth or activated clay. This clay has a special structure that absorbs the color pigments from the oil. Afterwards, the oil is passed through filters to remove the clay, which now contains all the unwanted color. The result is a beautifully light-colored oil.

Step 4: Deodorization – Removing Smell and Taste

This is the final and most complex step. The oil is heated to a high temperature (over 200°C) under a strong vacuum. Live steam is then injected directly into the hot oil. The combination of high heat, vacuum, and steam works to strip away any remaining traces of smell and taste. It also removes the last traces of FFAs. This process is done in a special stainless steel vessel called a deodorizer. After deodorization, the oil is cooled down. The final product is the fully refined, stable, and tasteless RBD sunflower oil that is ready for bottling and selling.

How Do You Choose the Right Refining Equipment?

You choose your refining equipment based on your planned production capacity. The technology is the same, but the scale of the machinery changes. We offer three main types of refinery setups for a sunflower oil refining business. They are batch type, semi-continuous type, and fully continuous type. Choosing the right one is the most important decision for your budget and long-term goals. As a factory-direct manufacturer, we can help you analyze your needs and select the most cost-effective solution.

| Refinery Type | Capacity (Tons/Day) | Best For… | Your Advantage |

|---|---|---|---|

| Batch Type | 1 – 20 TPD | Start-ups, small-scale producers. | Lowest initial investment; flexible for different oils. |

| Semi-Continuous | 20 – 50 TPD | Growing businesses; medium-scale plants. | Better efficiency than batch; good balance of cost and capacity. |

| Fully Continuous | 50+ TPD | Large industrial producers. | Lowest operational cost per liter; highest automation and consistency. |

A batch type refinery is the best starting point for a new business. All four refining steps are done one after another in the same set of vessels. It requires more manual operation but has the lowest initial investment cost. A semi-continuous refinery has a mix of batch and continuous processes, offering better efficiency for a medium-sized plant. A fully continuous refinery is a large, automated plant where oil flows non-stop through each stage. It has the highest installation cost but the lowest labor and energy cost per liter of oil produced, making it ideal for large-scale industrial production.

Preparatory work before commencing the refining equipment business

- Selecting suitable raw materials: Choose high-quality, fresh sunflower seeds as raw materials. Premium sunflower seeds should feature plump kernels, uniform color, and low impurity content.

- Bulk Purchasing: Based on production plans and market demand, strategically arrange procurement batches to secure more favorable purchase prices.

- Market Demand Analysis: Gain an in-depth understanding of the target market’s demand scale, growth trends, and consumption preferences for sunflower seed oil. Utilize data from market research agencies, industry reports, and communication with distributors and retailers to identify demand characteristics across different regions and consumer groups, such as packaging specifications, price ranges, and quality requirements.

- Storage Management: Establish a scientific raw material storage management system to ensure sunflower seeds remain free from moisture, mold, and insect infestation during storage. Utilize storage methods such as ventilation, drying, and low-temperature conditions to extend the shelf life of sunflower seeds.

- Processing Technology: Employing a multi-stage refining process (including pretreatment, pressing, filtration, hydration degumming, alkali refining for acid removal, bleaching for decolorization, and vacuum deodorization) maximizes nutrient retention while enhancing oil color, aroma, and taste.

- Automation Level: Highly automated equipment (such as intelligent control systems that centrally manage production processes) can reduce manual operations, lower production costs, and enhance production efficiency.

Trends in Refining Equipment Development

With the advancement of Industry 4.0, intelligent and automated solutions have become the core direction for refining machine development. Modular design has emerged as a new industry trend, reducing customers’ installation and commissioning costs by 30% while supporting flexible scalability for daily processing capacities ranging from 300kg to 5 tons.

Refining processes are evolving toward multi-stage systems to enhance oil quality. For example, the four-stage purification module includes: an enzymatic degumming system (with online pH monitoring ensuring >98.5% phospholipid removal rate), a rotary packed bed deacidification tower (microbubble injection technology achieves 99.5% fatty acid separation efficiency), a three-stage adsorption decolorization tower (dynamic mixer reduces pigment adsorption time to 12 minutes), and a four-stage steam deodorization unit (89% vitamin E retention at 260°C).

Latest Developments:

- Energy Recovery Systems: New oil refinery plant designs include advanced heat exchangers that recover and reuse heat, significantly cutting down on energy costs.

- Zero Effluent Discharge: Modern plants are being designed to treat and reuse water, minimizing environmental impact.

- Increased Automation: Advanced PLC control systems reduce the need for manual operators, improve consistency, and allow for remote monitoring of the plant.

Commencing Refining Machine Operations

Starting a sunflower oil refining business is a proven way to create a high-value food product. The process involves four key steps: degumming, neutralization, bleaching, and deodorization. Each of these steps removes specific impurities to produce clear, stable, and tasteless RBD sunflower oil. Your most important decision is choosing the right scale of equipment—batch, semi-continuous, or fully continuous—to match your production goals and budget.

The best way to get started is to develop a solid business plan that analyzes the local market conditions for crude oil supply and refined oil demand. Subsequently, by partnering with experienced Fude machinery manufacturers, we can provide you with a comprehensive, reliable, and efficient processing plant solution.

Related recommendations

-

Introduction to the functions of industrial drum dryer

610Industrial drum dryer is a common drying equipment suitable for drying a large amount of materials.

View details -

What are the advantages and disadvantages of hydraulic oil press

571As a commonly used oil extraction equipment, hydraulic oil press has its unique advantages and disadvantages. Let me introduce it to you ,

View details -

Which model of olive oil press is recommended

661It is recommended to use a spiral oil press, which can be multifunctional for pressing vegetable oils such as olives, walnuts, corn germ, safflower seeds, seabuckthorn seeds, flaxseeds, cocoa beans, coffee beans, etc.

View details -

What types of oil are suitable for hydraulic oil presses

540Hydraulic oil presses are suitable for a variety of oil types, especially those with high oil content, high oil quality requirements, or requiring cold pressing

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business