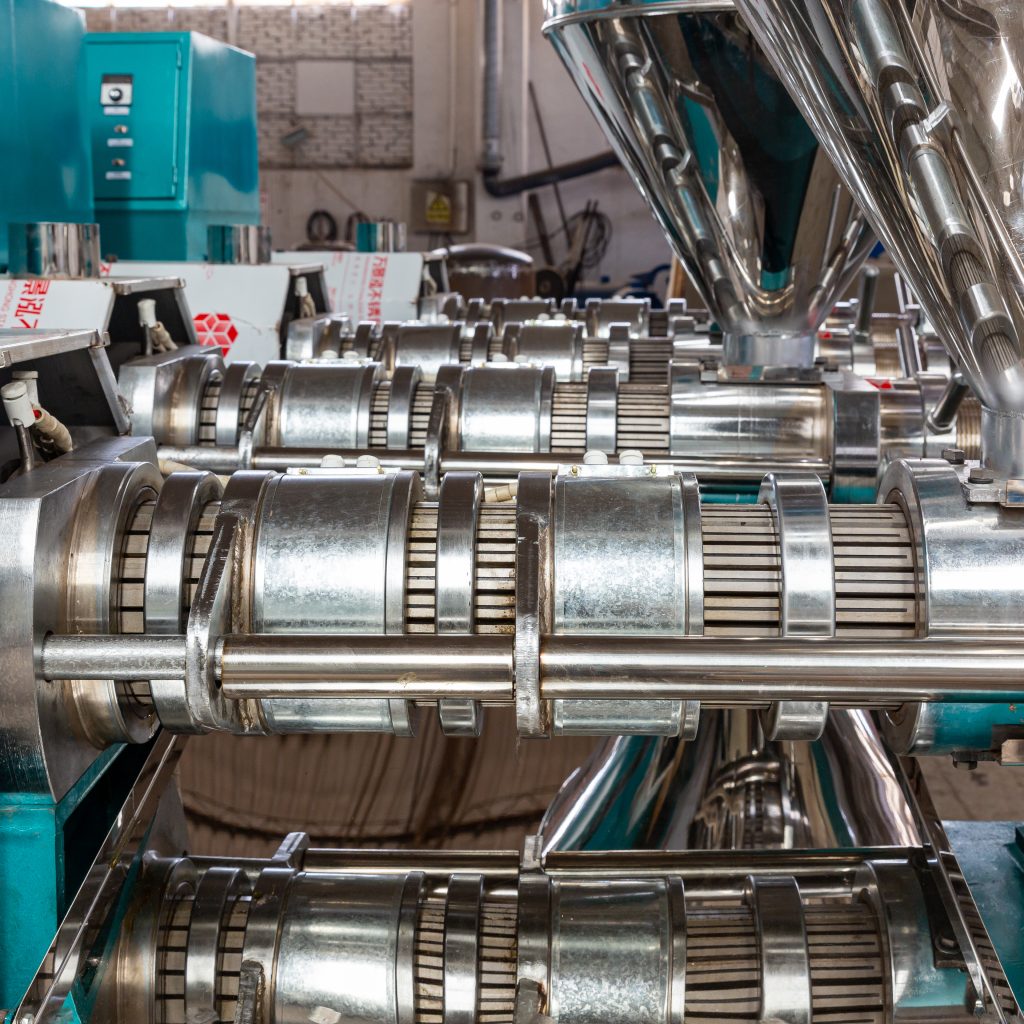

rapeseed oil press

Rapeseed oil presses are oil extraction equipment used to extract edible oils from rapeseed through physical pressing or solvent extraction processes.

Small-scale models suit household operations, while medium-to-large presses serve oil mills and processing plants to meet large-scale production demands.

Table of Contents

- Definition of screw oil press

- Working video of canola oil press machine

- Oil press for sale: parameter guide

- Working principle of small oil press

- Product Advantages of Tea Seed Oil Press

- Oil yield of oil press: the difference between raw materials

- How to choose an oil press

- Oil Press Production Line: Increasing Production

- About Fude Machinery

Definition of screw oil press

Screw oil press is a kind of edible oil processing equipment that operates on the principle of hydraulic full-automatic, and it pushes the material billet through the rotation of the screw shaft to realize continuous and efficient oil and grease pressing. Its core advantage lies in its compact structure, easy operation and high oil yield, which is widely used in the scenarios of individual households, small-scale oil mills and agricultural cooperatives, supporting the pressing of more than 30 kinds of oil crops, such as peanuts, soybeans, rapeseed, oil sunflower and so on.

- Supports two modes of cold pressing and hot pressing, adapting to different oilseed characteristics.

- Vacuum filtration system can quickly separate the oil residue, guarantee the oil quality is pure and meet the health quarantine standard.

Working video of canola oil press machine

The oil extraction principle of castor oil press machine mainly utilizes the oil extraction screw rotating in the pressing chamber to squeeze out the oil material. After adding the oil material in the inlet, the screw rotates to push the oil material into the pressing chamber, which gradually deforms the oil material and separates it from the oil material through strong pressure. Meanwhile, the pressed oil residue is discharged out of the machine through the oil residue outlet and stored in the waste residue storage box.

Oil press for sale: parameter guide

| Oil press model | 60 type | 70 type | 80 type | 100 type | 125 type | 150 type |

| Squeezing chamber diameter | 55mm | 65mm | 80mm | 101mm | 125mm | 150mm |

| Squeezing screw speed | 52r/min | 48r/min | 47r/min | 38r/min | 36r/min | 35r/min |

| Squeezing screw speed | 2.2kw | 3kw | 5.5kw | 7.5kw | 15kw | 18.5kw |

| Processing capacity | 30-60kg/h | 50-80kg/h | 65-130kg/h | 140-280kg/h | 300-400kg/h | 500-600kg/h |

| Overall weight | 220kg | 280kg | 780kg | 1100kg | 1280kg | 1420kg |

Customized output parameters according to customer requirements

Working principle of small oil press

- The press screw is made of high carbon steel or chrome 40, quenched by high frequency, heat-resistant treatment, high hardness, wear-resistant, adaptable to high-temperature and high-pressure continuous operation, the service life of the traditional materials up to 8-10 times.

- The press chamber is designed as a progressive pressure structure, the diameter of the root circle of the screw is gradually thickened, and the pitch of the screw is gradually reduced, which pushes the material embryo forward and produces overturning and relative movement at the same time, destroying the colloidal structure of the oil material through friction and heat generation, and promoting the precipitation of oil and grease.

- Multi-stage press and temperature control system

- Adopting the principle of multi-stage propulsion and gradual pressurization, the pressure of the press chamber increases rapidly, realizing one-time fission and separation of oil.

- Equipped with infrared temperature control system, automatic control of pressing temperature (120-160 ℃) and moisture, soften and activate the oil molecules, improve the oil yield and ensure the quality of oil.

- It supports two modes of cold pressing and hot pressing, adapting to different oilseed characteristics and meeting market demand.

Product Advantages of Tea Seed Oil Press

- Significant increase in oil yield

- The oil yield of the physical press type is 2-3 percentage points higher than that of the traditional equipment (e.g., 2-6 jin more oil per 100 jin of peanut rice), and the screw press further optimizes the oil yield efficiency through the design of the bionic cutting surface (e.g., 0.05mm spacing of the press rods) and the progressive thickening structure.

- Suitable for a wide range of oils

- It can process more than 30 kinds of oil crops such as peanuts, soybeans, rapeseeds, walnuts, etc. It supports hot and cold double pressing mode.

- The oil is pure and meets health standards

- Vacuum negative pressure filtration technology removes residue and the grease is clear and non-foaming with low cholesterol content.

Oil yield of oil press: the difference between raw materials

- Soybean: oil yield is about 12%-18%, and the crushed soybean cake can be used as feed or protein raw material.

- Canola (rapeseed): oil yield 30%-45%, is the main source of rapeseed oil.

- Peanut: oil yield 40%-50%, peanut oil has strong aroma and high market value.

- Cottonseed: oil yield 10%-20%, need to be pressed after detoxification treatment, cottonseed oil can be used for industry or food.

- Sunflower seed (sunflower): oil yield 25%-40%, sunflower oil is rich in unsaturated fatty acids.

- Sesame: oil yield 45%-55%, sesame oil (sesame oil) has a unique flavor and is suitable for cold pressing.

- Flaxseed: oil yield 30%-40%, flaxseed oil is rich in α-linolenic acid, suitable for healthy cooking oil.

- Su seed (perilla seed): oil yield 35%-45%, Su seed oil has medicinal value.

- Safflower seed: oil yield 20%-30%, safflower seed oil is rich in vitamin E.

Olive

Coconut

Flaxseed

Sesame

- Tea seeds: oil yield 20%-30%, tea oil is high-end cooking oil, storage resistance.

- Walnut kernel: oil yield 60%-70%, walnut oil is rich in nutrition, suitable for infants and children.

- Almond: oil yield 40%-50%, almond oil can be used in food or cosmetics.

- Coconut meat: oil yield 60%-70%, coconut oil is heat resistant, suitable for cooking or industrial use.

- Olives: 15-25% oil yield, olive oil is the core oil of the Mediterranean diet.

- Palm fruit: 20%-30% oil yield, palm oil is the most productive vegetable oil in the world.

Avocado oil

Sunflower oil

Olive oil

Sesame oil

How to choose an oil press

Raw Material Adaptive

- Screw presses are suitable for most oilseed crops, but animal fats and oils or high-viscosity raw materials require pretreatment (e.g., melting, filtering).

- Pressing process

- Hot pressing: suitable for high oil content raw materials (e.g. peanuts, rapeseed), high oil output rate

- Cold pressed: suitable for low oil content or raw materials that need to retain nutrients (e.g. flaxseed, walnuts)

- Capacity determines model

- Family workshop: choose small-sized machine (such as 6YL-80 type), processing capacity 65-130Kg/h, suitable for peanut, sesame and so on.

- Small and medium-sized oil workshop: choose medium-sized machine (e.g. 6YL-120 type), processing capacity 250-400Kg/h, support multi-raw material switching.

- Industrial level: choose large-sized machine (such as 6YL-160 type), processing capacity 300-550Kg/h, need to support pre-treatment equipment.

Oil Press Production Line: Increasing Production

A complete set of oil extraction equipment usually includes three core equipments: main machine of oil press, frying pot and oil filter, and auxiliary equipments such as feeding machine, shelling machine, embryo press, oil storage tank and filling machine can be selected according to the demand, so as to realize the whole process automation from raw material pre-treatment to finished oil filling.

- Screw oil press: the most widely used, suitable for continuous production, with large processing capacity, high oil yield.

- Frying Machine: Frying the oil material, destroying the cell structure, increasing the oil yield, and improving the flavor of the oil.

- Centrifugal oil filter: Filter the pressed gross oil, remove phospholipids, impurities, etc., and improve the transparency and stability of the oil.

- Feeding machine: automatically conveying the oil into the frying pan, reducing manpower feeding and labor intensity.

- Sheller: removes the shells of oilseeds (e.g. peanuts, sunflower seeds) to increase oil yield and reduce equipment wear.

- Oil storage tank: store the filtered finished oil for subsequent filling or sale.

About Fude Machinery

We are Fude Machinery, a leading B2B edible oil processing equipment manufacturer based in Zhengzhou, China. As a direct seller, we offer a full range of durable oil extraction machinery at competitive prices to customers around the world. We specialize in designing and building customized, complete delivery solutions for all types of oilseeds and have expertise in oil extraction raw materials. Our equipment is trusted by companies in several countries.

Contact us for more quotes

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business