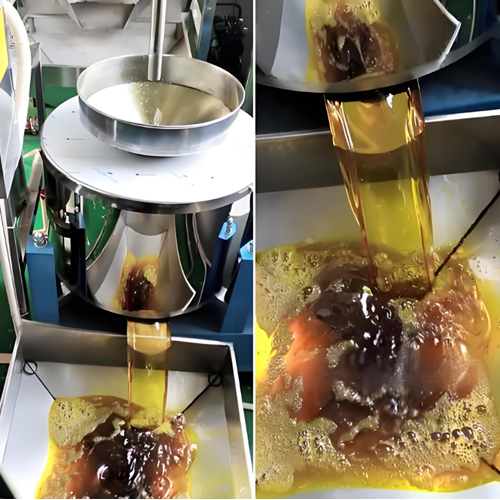

centrifugal oil filter

Food oil refining equipment

Centrifugal oil filter is a kind of mechanical equipment that utilizes centrifugal force to realize efficient separation of oil, water and impurities, which is widely used in the fields of electric power, shipbuilding, machinery manufacturing, food processing and so on.

Its core principle is to generate a strong centrifugal force through the high-speed rotating drum, so that the components of different densities in the oil (such as solid particles, water) layered precipitation, so as to achieve the purpose of purification.

Table of Contents

- Food oil refining equipment

- The characteristics of centrifugal oil filters

- What are the advantages of a small refiner

- Edible Oil Filter Application Scope

- The advantages of centrifugal oil filters

- When is a Centrifugal Filter the Best Choice For You?

- How to Choose the Right Centrifugal Oil Filter?

- Oil Filter Parameter Table

- Oil filters for sale: total price and proposal

The characteristics of centrifugal oil filters

- Centrifugal Force Driven Separation

- The drum rotates at a high speed at thousands of revolutions per minute. Impurities in the oil (e.g. metal particles, sludge) are thrown to the inner wall of the drum due to their density being greater than that of the oil, water forms a separate liquid layer due to the difference in density, and clean oil flows out through the center of the drum.

- Separation efficiency: Centrifugal force can be thousands of times of gravity, even micron-sized impurities (e.g. 1μm particles) can be effectively filtered out.

- Separation Mode: Supports various modes such as clarification (liquid-solid separation), purification (liquid-liquid-solid separation), etc., adapting to different oil treatment needs.

- Physical Separation without Consumables

- Unlike traditional cloth filters, centrifugal oil filters separate impurities in a purely physical way, eliminating the need to replace filter cartridges or cloths, resulting in lower long-term costs and avoiding performance degradation due to clogging of the filter media.

What are the advantages of a small refiner

The main advantages are speed, efficiency, and zero ongoing costs for consumables. For any business owner, these three things directly translate into higher profit. A centrifugal oil filter is a smart investment because it improves your workflow and saves you money every single day. Let’s compare it to older, traditional methods to see why it is so much better.

Older methods like natural settling can take days. Plate-and-frame filters are slow and require you to constantly buy and change messy filter cloths. A centrifugal filter solves all these problems.

As a manufacturer of oil filtration equipment, we have designed our centrifugal models to be the most efficient solution for small and medium-sized oil mills. It is a one-time investment that pays you back with speed and savings.

| Feature | Centrifugal Filter | Plate & Frame Filter | What This Means for Your Profit |

|---|---|---|---|

| Speed | Very Fast (Continuous) | Slow (Batch) | You can filter and bottle your oil on the same day, improving cash flow. |

| Consumables | None | Needs Filter Cloths | You save a lot of money because you never have to buy replacements. |

| Labor Cost | Very Low (Automatic) | High (Manual Cleaning/Changing) | Your workers can do more valuable tasks instead of cleaning filters. |

| Filtration Effect | Excellent (Clear Oil) | Good (Can Leak) | You get a consistent |

Edible Oil Filter Application Scope

Centrifugal oil filters are suitable for purification treatment of lubricating oil, heavy diesel, edible rapeseed oil, tea oil, peanut oil, etc. in power plants, ships, and large mechanical equipment. When used for the treatment of turbine oil in power plants, the bypass is connected to the main oil tank of the steam turbine for random operation, which can timely filter out moisture and impurities in the oil, improve the quality of operating oil, slow down the aging rate of oil, and ensure the safe operation of the steam turbine, which will have a positive effect on the purity of edible oil.

The advantages of centrifugal oil filters

- The centrifugal head has a fast rotation speed and good separation effect for oil, water, and impurities.

- Equipped with heating and temperature control devices, increasing the oil temperature appropriately can reduce the viscosity of the oil and the binding force between oil and water, which is beneficial for improving the oil-water separation effect.

- Small size, large processing flow, easy to operate, and can be used in a flowing manner.

- The starting characteristics are relatively soft, making it smooth and safe to start, stop, or rotate at high speeds; The oil inlet is equipped with an electromagnetic valve, which automatically cuts off the oil supply circuit in case of abnormal power outage.

When is a Centrifugal Filter the Best Choice For You?

A centrifugal oil filter is the best choice right after your oil press and for purifying used frying oil. This machine is incredibly versatile, but it truly excels in these two common business applications. Its ability to quickly handle oil with a high concentration of solids makes it a perfect match for these tasks. It is the workhorse of oil purification.

For Crude Oil Right After the Press

This is the most common and important use. When you use a screw oil press to extract oil from seeds like peanuts, sunflower, or rapeseed, the crude oil that comes out is full of fine seed particles. A centrifugal oil filter is the ideal machine to connect directly to your press. It can handle the continuous flow of crude oil and clarify it in real-time. This creates a highly efficient production line: press, filter, and then bottle. A small business can process hundreds of kilograms of oil in a single day using this setup.

For Purifying Used Frying Oil

For businesses in the food service industry, like restaurants or snack food factories, this is a huge money-saver. Frying oil becomes full of tiny food particles and crumbs over time. This makes the oil dark and gives it a burnt taste. Instead of throwing this expensive oil away, you can run it through a centrifugal oil filter. The filter will remove all the suspended solids, making the oil clean and clear again. This can double or even triple the life of your frying oil, leading to massive savings on your operating costs.

oil filter

How to Choose the Right Centrifugal Oil Filter?

You should choose a filter based on its processing capacity and the material it is made from. Not all filters are the same. Buying the right one for your specific needs is crucial for getting the best performance. As a manufacturer, we offer a range of models, and we always guide our clients to make the smartest choice for their business.

Motor and Stability: Look for a machine with a quality motor and good dynamic balancing. A well-balanced machine will run smoothly without vibrating, which makes it safer and extends its lifespan.

Capacity: This is the most important factor. The filter’s capacity is measured in how many kilograms or liters of oil it can process per hour. You must match the filter’s capacity to the output of your oil press. If your press produces 100 kg of crude oil per hour, you need a filter that can handle at least that amount.

Material: For processing edible oil, this is not negotiable. All parts that come into contact with the oil, especially the internal drum, must be made of food-grade stainless steel. This is to ensure your final product is safe, pure, and meets health standards.

Oil Filter Parameter Table

| Product Model | Power (KW) | 转速(r/min) | yield | Overall weight (kg) |

| 40M | 1.5 | 2000 | 10 pounds/time | 80 |

| 50M | 1.5 | 1800 | 40 pounds/time | 140 |

| 60M | 1.5 | 1800 | 60 pounds/time | 160 |

| 80M | 2.2 | 1800 | 80 pounds/time | 180 |

Oil filters for sale: total price and proposal

A centrifugal oil filter is an essential, high-return investment for any modern oil processing business. It offers unmatched speed, superior efficiency, and the incredible benefit of having zero consumable costs. By using the simple power of centrifugal force, it transforms cloudy crude oil into a clean, sellable product in minutes, not days. This technology directly boosts your productivity and your profit margin.

Whether you are running a small oil mill or a busy restaurant, this machine will save you time, labor, and money. It is a simple, robust, and brilliant solution to the universal problem of oil purification.

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business