Commercial Oil Press

Oil Press Machine

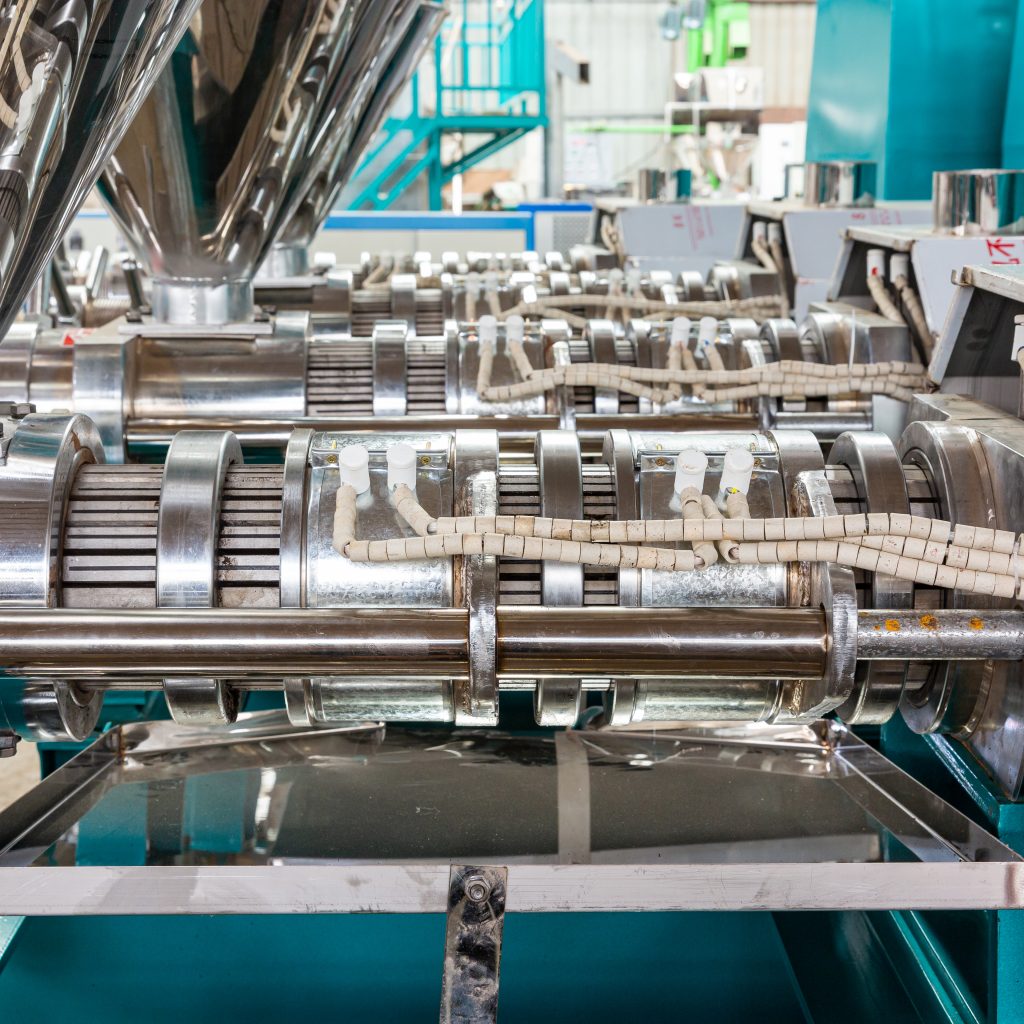

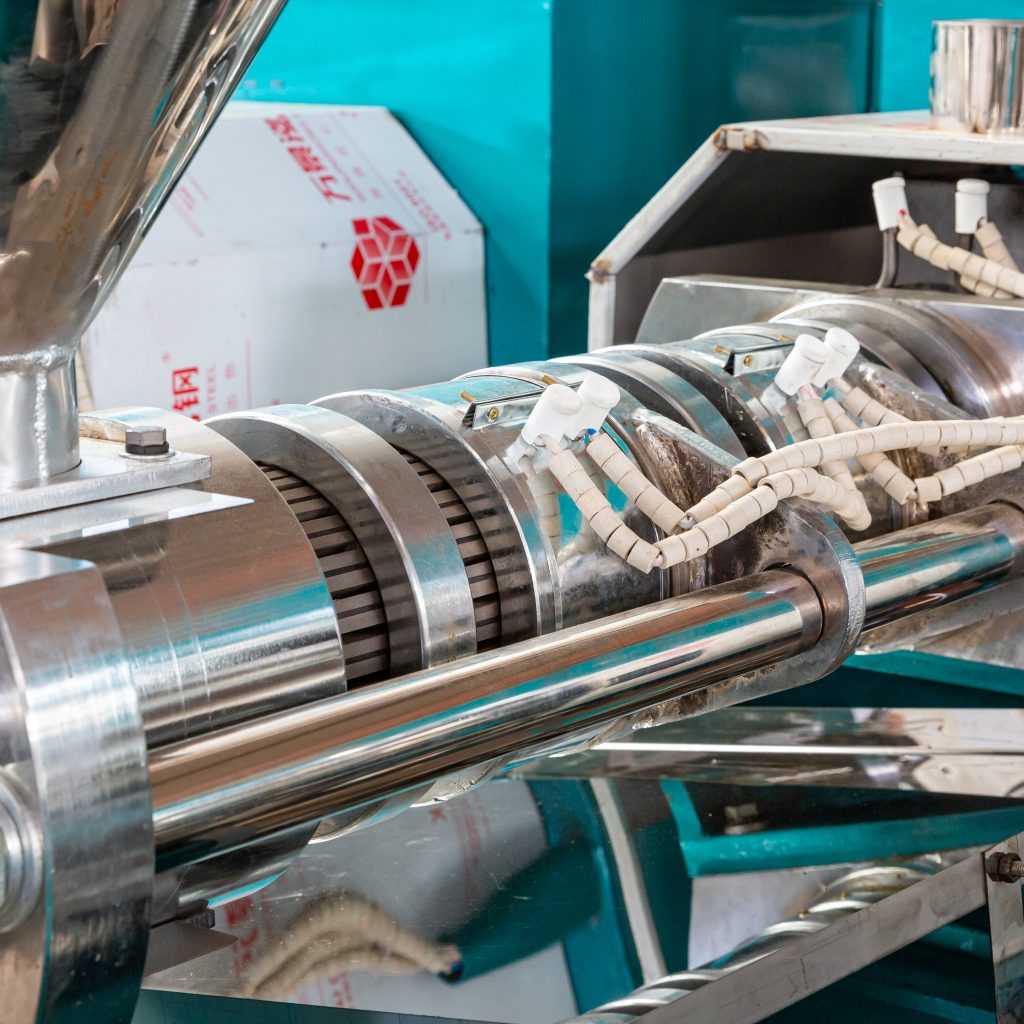

Screw oil press is a kind of multifunctional equipment widely used in the field of edible oil processing, and its product design and functional features reflect the integration of modern industrial technology.

Covering a wide range of needs from small domestic to large commercial, the processing capacity ranges from 50kg/h to 500kg/h, the motor power is 3-30kW, suitable for peanut, sesame, soybean, sunflower seeds and other raw materials.

Table of Contents

- Oil Press Machine

- Industrial oil press operation video

- soybean oil press for salparameters

- Why is it called a sunflower oil pressing machine?

- Multi-function oil press working principle

- Raw material analysis of oil press

- What are the factors affecting the oil yield of oil press machine

- How to choose the right oil press equipment

Industrial oil press operation video

The oil extraction principle of a screw press mainly uses the oil extraction screw to rotate in the pressing chamber and squeeze out the oil material. After adding the oil at the feeding port, the screw rotates to push the oil into the pressing chamber, causing the oil to gradually deform and separate from the oil through strong pressure. Meanwhile, the squeezed oil residue is discharged from the machine through the oil residue outlet and stored in the waste residue storage tank.

soybean oil press for salparameters

| Oil press model | 60 type | 70 type | 80 type | 100 type | 125 type | 150 type |

| Squeezing chamber diameter | 55mm | 65mm | 80mm | 101mm | 125mm | 150mm |

| Squeezing screw speed | 52r/min | 48r/min | 47r/min | 38r/min | 36r/min | 35r/min |

| Squeezing screw speed | 2.2kw | 3kw | 5.5kw | 7.5kw | 15kw | 18.5kw |

| Processing capacity | 30-60kg/h | 50-80kg/h | 65-130kg/h | 140-280kg/h | 300-400kg/h | 500-600kg/h |

| Overall weight | 220kg | 280kg | 780kg | 1100kg | 1280kg | 1420kg |

Customized output models according to customer needs

Why is it called a sunflower oil pressing machine?

sunflower oil press machine for sale is based on the design principle of the oil press: there is a spiral shaft inside the oil press, which generates pressure through the rotation of the screw, forcing the raw material molecules to rupture, thereby achieving the purpose of oil extraction. So this type of oil press with a spiral shaft is called a spiral oil press. Spiral oil press is a common oil pressing equipment widely used in industries such as food, chemical, and pharmaceutical. It obtains oil by squeezing materials, which has the advantages of simple operation, low cost, and high oil content.

Technical characteristics of oil press equipment

- Multi-stage pressing and efficient oil production

- Adopting directional pressure, multi-stage propulsion technology, combined with vacuum diverter, to make the oil residue separation more thorough, and improve the oil yield.

- Electronic program control system automatically adjusts the pressing temperature (e.g. Model 70 oil press is equipped with a 3kW heating system) to optimize the efficiency of oil extraction.

- Mechatronic design, one person can operate multiple equipment, reduce labor costs

Multi-function oil press working principle

Screw oil press is a kind of edible oil processing equipment that operates on hydraulic full-automatic principle, and it pushes the material billet by rotating the screw shaft to realize continuous and efficient oil and grease pressing. Its core advantage lies in its compact structure, easy operation and high oil yield, which is widely used in the scenarios of individual households, small oil mills and agricultural cooperatives.

- The press screw is made of high carbon steel or chrome 40, quenched by high frequency, heat-resistant treatment, high hardness, wear-resistant, adaptable to high-temperature and high-pressure continuous operation, the service life of the traditional materials up to 8-10 times.

- The press chamber is designed as a progressive pressurized structure, the diameter of the root garden of the screw is gradually thickened, and the pitch of the screw is gradually reduced, which pushes the material embryo forward and produces overturning and relative movement at the same time, destroying the colloidal structure of the oil material through friction and heat generation, and promoting the precipitation of the oil and grease.

- Hot & Cold & Vacuum Filtration

- The oil press supports both cold pressing and hot pressing modes, adapting to different oilseed characteristics.

- Vacuum filtration system can quickly separate the oil residue, guarantee the oil quality is pure and meet the health quarantine standard.

Raw material analysis of oil press

It can easily press various materials such as olives, palm fruits, flaxseeds, coconuts, peanuts, sesame, corn germ, avocado, etc. For more materials, please consult customer service

- Soybean: oil yield is about 12%-18%, and the crushed soybean cake can be used as feed or protein raw material.

- Canola (rapeseed): oil yield 30%-45%, is the main source of rapeseed oil.

- Peanut: oil yield 40%-50%, peanut oil has strong aroma and high market value.

- Cottonseed: oil yield 10%-20%, need to be pressed after detoxification treatment, cottonseed oil can be used for industry or food.

- Sunflower seed (sunflower): oil yield 25%-40%, sunflower oil is rich in unsaturated fatty acids.

- Sesame: oil yield 45%-55%, sesame oil (sesame oil) has a unique flavor and is suitable for cold pressing.

- Flaxseed: oil yield 30%-40%, flaxseed oil is rich in α-linolenic acid, suitable for healthy cooking oil.

- Su seed (perilla seed): oil yield 35%-45%, Su seed oil has medicinal value.

- Tea seeds: oil yield 20%-30%, tea oil is high-end cooking oil, storage resistance.

- Walnut kernel: oil yield 60%-70%, walnut oil is rich in nutrition, suitable for infants and children.

- Almond: 40%-50% oil yield, almond oil can be used in food or cosmetics.

- Coconut meat: oil yield 60%-70%, coconut oil is heat resistant, suitable for cooking or industrial use.

- Olives: 15-25% oil yield, olive oil is the core oil of the Mediterranean diet.

- Palm fruit: 20%-30% oil yield, palm oil is the most productive vegetable oil in the world.

Coconut oil

palm oil

peanut oil

Flaxseed oil

What are the factors affecting the oil yield of oil press machine

- Raw material quality: The quality of raw materials directly affects the oil extraction effect. High quality peanut raw materials with high oil content and low impurities can improve oil yield.

- rosin oil press performance: The performance of the oil press plays a crucial role in the oil pressing effect. An efficient oil press can more fully extract oil, improve oil yield and quality.

- Pressing process: Appropriate pressing process parameters, such as temperature, pressure, time, etc., can affect the oil extraction effect. Optimizing the process can improve oil extraction efficiency.

- Oil pretreatment: Proper pretreatment of oil, such as cleaning, shelling, crushing, etc., can improve the working efficiency of the oil press.

- Operator skills: The operator’s proficiency and skill level in operating the oil press can also have an impact on the oil extraction effect.

- Daily maintenance: Regular maintenance and upkeep of the oil press to ensure that the equipment is in good working condition, which is beneficial for improving the oil extraction efficiency.

- In order to achieve better oil extraction results, it is necessary to comprehensively consider the above factors and take corresponding measures for optimization and improvement. At the same time, attention should be paid to safety production and equipment maintenance to ensure the smooth progress of the oil extraction process.

How to choose the right oil press equipment

- Selection of equipment according to raw materials

- Screw presses are suitable for most oil crops, but animal fats and oils or high viscosity raw materials need pretreatment (e.g. melting, filtering).

- Special oilseeds (e.g. castor seed) require special chamber design to avoid toxin residue or equipment damage.

- Pressing process

- Hot pressing: suitable for raw materials with high oil content (e.g. peanut, rapeseed), effectively increase the oil yield

- Cold pressing: suitable for raw materials with low oil content or need to retain the nutrition (e.g. flaxseed, walnut), the oil quality is pure.

- Stand-alone or production line configurations

- Family workshop: choose small-sized machine (such as 60-80 type), processing capacity 65-130Kg/h, suitable for peanut, sesame and so on.

- Small and medium-sized oil workshop: choose medium-sized machine (such as 80-120 type), processing capacity of 250-400Kg/h, support multi-raw material switching.

- Industrial level: choose large-sized machine (such as 120-200 type), processing capacity of 300-600Kg/h, need to support pre-treatment equipment.

- A complete set of oil extraction equipment usually includes three core equipments: oil press host, frying pot, oil filter, and auxiliary equipments such as loader, sheller, presser, storage tank, filling machine, etc. according to the demand, in order to realize the whole process automation from raw material pre-treatment to finished oil filling.

Learn more about oil press prices and get a free quote.

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business