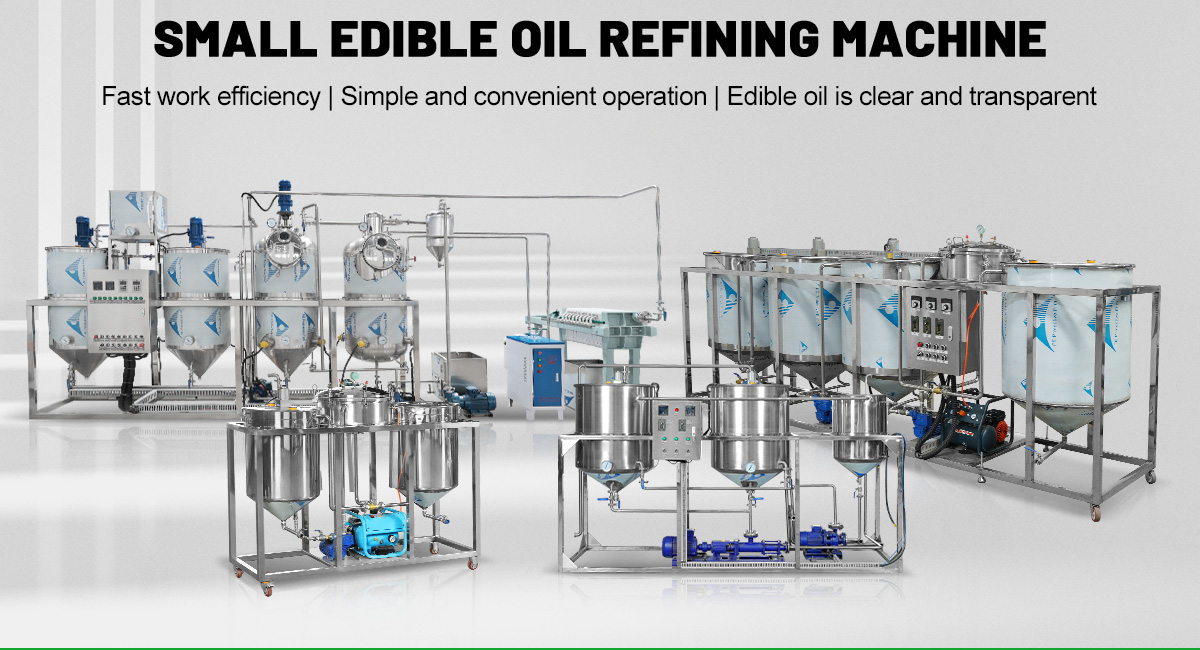

edible oil refining equipment

What is a edible oil refining machine

A refining machine is a mechanical device that removes impurities from raw materials through physical or chemical methods, thereby enhancing the purity and quality of the product. It is widely used in various industries such as edible oil, rubber, fats and oils, precious metals, and chocolate. Depending on the application field and process requirements, the design, functionality, and operation of refining machines vary significantly.

Table of Contents

- What is a edible oil refining machine

- Refining machine: An analysis of the core equipment for transforming crude oil into first-grade edible oil

- The working principle of crude oil refining machine

- Scope of application of edible oil refining machine

- The effectiveness of using a palm oil refining machine

- The advantages of refining equipment

- Intermittent refining machine vs continuous refining machine

- What raw materials are suitable for use in a refining machine

- Refining equipment: core components and materials

- Oil Filter for Sale: Comprehensive Suggestions

Refining machine: An analysis of the core equipment for transforming crude oil into first-grade edible oil

The food oil refining machine converts crude oil obtained through pressing or extraction into edible oil that meets national standards through five core processes: degumming, deacidification, decolorization, deodorization, and dewaxing (which can be used according to the material combination):

- Degumming

- Principle: Leveraging the hydrophilic nature of phospholipids, colloidal substances are precipitated and separated through heating and hydration.

- Equipment: hydration pot, centrifuge.

- Effect: Remove colloidal impurities such as phospholipids and proteins to avoid precipitation during subsequent processing.

- Deacidification

- Traditional alkali refining method: Add sodium hydroxide to neutralize free fatty acids, resulting in soapstock which is then separated.

- Advantages: Wide applicability and low cost.

- Disadvantages: high refining consumption (about 3%-5%), requiring supporting wastewater treatment facilities.

- Physical refining method

- High-temperature steam directly strips free fatty acids without the need for chemical alkali solution.

- Advantages: low refining loss (about 1%-2%), no pollution, suitable for inferior crude oil.

- Equipment: Deacidification tower, steam injection device.

- decolorize

- Principle: Utilize activated clay or activated carbon to adsorb pigments, metal ions, and residual phospholipids.

- Equipment: Decolorizing tower, plate and frame filter.

- Effect: Enhance oil transparency and improve flavor.

- deodorization

- Principle: Under high temperature (above 260℃) and high vacuum (3 mbar) conditions, odor substances are removed through steam agitation.

- Equipment: Combined deodorization tower, heat exchanger.

- Effect: Ensure pure flavor of oil products and extend shelf life

The working principle of crude oil refining machine

palm oil refining machine can be divided into chemical refining and physical refining. In order to improve oil quality and reduce refining consumption, we generally use the physical refining method. The physical refining process of peanut oil is as follows: crude oil – heater – static mixer – acid reactor – multi effect mixer – heater – centrifugal mixer – water washing centrifuge – heater – vacuum dryer – clay mixer – decolorization – filtration – decolorization clear oil tank – gas separator – heat exchange – deodorization – heat exchange – finished oil.

Scope of application of edible oil refining machine

We use edible oil almost every day in our daily lives. Generally, the crude oil or extracted crude oil needs to be refined and processed by oil refining equipment before it can become edible oil for people. The emergence of refining equipment has solved the problem of inedibility of extracted crude oil. After being treated by refining equipment, the oil quality has also been improved.

The effectiveness of using a palm oil refining machine

The purpose of edible oil refining equipment is to remove impurities and achieve the standard of finished edible oil. The main process of this process is: crude oil – degumming – neutralization – decolorization – deodorization – separate extraction. Add water for hydration and degumming, neutralize with alkali or steam distillation for deacidification, add adsorbent activated clay or activated carbon for decolorization, deodorize under high temperature and negative pressure, and remove low boiling volatile substances that produce oil fumes.

The advantages of refining equipment

Oil refining usually refers to the refinement of crude oil. The presence of impurities in crude oil not only affects the edible value and safe storage of the oil, but also brings difficulties to deep processing. However, the purpose of refining is not to remove all impurities in the oil, but to remove harmful and harmful impurities such as gossypol, protein, phospholipids, mucus, water, etc. that are harmful to food, storage, industrial production, etc., while beneficial impurities such as tocopherol should be retained. Therefore, according to different requirements and uses, the purpose of oil refining is to remove unnecessary and harmful impurities from the oil and obtain finished oil that meets certain quality standards.

Intermittent refining machine vs continuous refining machine

Continuous and batch refining machines exhibit significant differences in production mode, efficiency, energy consumption, environmental friendliness, equipment cost, and applicable scenarios

- Continuous refining machine

- Production mode: Realize full-process automated continuous operation, with no manual intervention required from raw material feeding, refining to finished product discharge, supporting 24-hour uninterrupted production.

- Efficiency advantage: Taking industrial oil refining as an example, continuous equipment can operate continuously for more than 45 days, requiring only external fuel (such as heavy oil or natural gas) for the initial startup. Subsequently, it utilizes its own generated exhaust gas to maintain combustion, significantly reducing fuel costs.

- Capacity scale: The daily processing capacity can reach tens or even hundreds of tons, making it suitable for large-scale industrial production.

- Intermittent refining machine

- Production mode: Adopting a cyclic operation of “feeding – refining – cooling – slagging”, each batch of raw materials needs to complete the entire process of heating, reaction, cooling, and slagging independently.

- Efficiency limitations: Taking industrial oil refining as an example, each batch needs to be cooled for several hours until it reaches the slag discharge temperature. The daily processing capacity is usually only 1-2 furnaces (approximately 10-20 tons), and the utilization rate of thermal energy is low, resulting in a significant waste of heat during the heating and cooling processes.

- Capacity scale: Suitable for small-scale or flexible production needs, but difficult to meet large-scale continuous production.

What raw materials are suitable for use in a refining machine

- Vegetable oil: various food oils such as rapeseed oil, soybean oil, linseed oil, peanut oil, sunflower seed oil, etc

- Animal oils: lard, butter, etc.

- Application scenarios

- Large oil factory: Utilizing a fully continuous physical refining line, with a daily processing capacity exceeding 500 tons, producing first-grade edible oil.

- Small and medium-sized oil mills: Utilize intermittent refining units to achieve integrated operations of degumming, deacidification, and decolorization, ensuring that the finished oil meets or exceeds Grade II standards.

- Specialty oil processing: Customized dewaxing and degreasing processes for high value-added oils such as rice bran oil and grape seed oil.

Refining equipment: core components and materials

- Degumming tank/Deacidification tank: Made of 304 stainless steel, it is corrosion-resistant and meets food-grade standards.

- Decolorization tower: Equipped with a steam agitation system to ensure sufficient contact between the adsorbent and the oil and fat.

- Combined deodorization tower: Integrating packed section and plate section to achieve efficient deacidification and deodorization.

- Heat exchanger: Utilizes waste heat from the system to reduce steam consumption, achieving energy conservation and environmental protection.

- Support intermittent, semi-continuous, or continuous production, and can be flexibly configured according to the scale of the oil plant.

- Integrating technologies such as microwave conditioning and centrifugal separation to enhance oil yield and preserve nutritional components.

Oil Filter for Sale: Comprehensive Suggestions

The scope of use for an oil refining machine is incredibly broad and diverse. While its most common application is producing edible oil for the food industry, its role is just as critical in other major sectors. It is a key piece of equipment for creating clean feedstock for the biofuel industry. It is essential for producing the pure, neutral oils required by the cosmetics industry. It is also a vital tool for creating specialized oils for various industrial products.

At Fude Machinery, we understand this wide scope. We have the experience to design and build a refining solution for any of these applications, at any scale.

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business