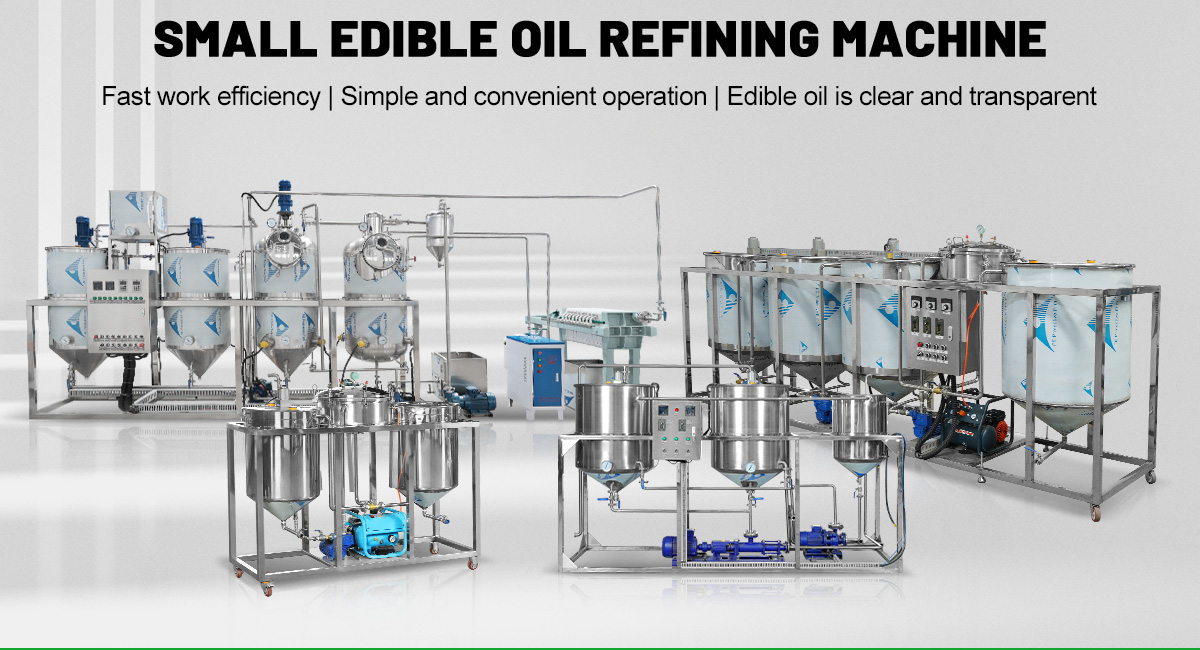

edible oil refining equipment

Definition of Refiner

A refiner is a mechanical device that removes impurities from raw materials by physical or chemical means and enhances the purity and quality of the product, which is widely used in a variety of industries such as food oils, rubbers, fats and oils, precious metals, chocolates, and so on.

Depending on the application and process requirements, there are significant differences in the design, function and operation of refiners.

Table of Contents

- Definition of Refiner

- Classification of refiners in different fields

- The working principle of refining equipment

- Applications of refining equipment

- Refiners for sale: Frequently Asked Questions

- Summary and Recommendation

Classification of refiners in different fields

- Oil and grease refining machine

- Purpose: Remove the free fatty acid, gum, pigment, odor and other impurities in the gross oil, and produce edible oil or industrial oil in accordance with the standard.

- Structural features:

- According to the processing scale, it is divided into batch type, semi-continuous type and continuous type equipment.

- The core module includes degumming tank, deacidifying tank, decolorizing tower, deodorizing tower, etc. Some of the equipments are integrated with dephosphorization function.

- Functional advantages:

- Degumming: remove phospholipids and other gums to prevent oxidization and deterioration of fats and oils.

- Deacidification: Neutralize the free fatty acid through alkali refining or physical distillation to enhance the stability of oil and grease.

- Decolorization: Adsorb pigment by activated white clay to improve the color of oil and grease.

- Deodorization: Remove odor substances under high temperature and vacuum conditions to enhance the flavor.

- Rubber Refiner

- Purpose: Remove hard impurities (such as metal particles, fibers, etc.) from the recycled rubber and enhance the purity of rubber.

- Structural features:

- The front and rear rollers have smooth surfaces and are in the shape of a waist drum, which squeezes the impurities from the center of the drum to the ends when running.

- Equipped with a cutter device, which can remove the impurities gathered at the edge of the film.

- The rollers are made of vanadium and titanium alloy cold hard cast iron, which is highly wear-resistant; the inner cavity is processed to ensure uniform temperature.

- Functional advantages:

- Overload protection device prevents damage to parts, and emergency braking system guarantees safety.

- The transmission system adopts hardened planetary gear reducer with low noise, high efficiency and long life.

- Chocolate refining machine

- Purpose: Remove the odor in chocolate material through mechanical kneading effect, improve the taste and dispersibility.

- Structural features:

- Roller reciprocating type: granite rollers move back and forth along the cylinder wall, long time rolling friction produces kneading effect.

- Plow mixing type: Vertical mixing column is equipped with scraper and plow mixing paddle to enhance the aerating effect and aroma.

- Three cylinders and three shafts double tumbling type: the diameter of the outer two cylinders is smaller than that of the middle cylinder, which shortens the refining time to less than 6 hours by double tumbling action.

The working principle of refining equipment

- Physical Refiner

- Principle: Separation of impurities by physical methods (e.g. filtration, adsorption, distillation) without changing the chemical properties of the substances.

- Applications: decolorization of fats and oils (adsorption of activated white clay), chocolate refining (mechanical kneading), physical purification of precious metals (distillation separation).

- Chemical refiner

- Principle: Removal of impurities or conversion of target substances by chemical reactions (e.g. neutralization, redox).

- Applications: deacidification of fats and oils (alkaline refining to neutralize free fatty acids), rubber refining (chemical softening of impurities).

- Compound Refiner

- Principle: Combination of physical and chemical methods for multi-stage purification.

- Applications: precious metal refining (chemical dissolution + electrolytic deposition), oil and grease refining (degumming + deacidification + decoloration + deodorization).

Applications of refining equipment

The largest use for oil refining machines is in the food industry. This is the market most people know. After you press seeds like soybeans or sunflowers, you get crude oil. This crude oil contains things that make it unstable. It can go bad quickly and has a strong flavor. An oil refining machine removes these impurities. The process typically involves degumming, neutralization, bleaching, and deodorization. The final product is called RBD oil (Refined, Bleached, Deodorized). It is light in color, has a neutral taste, and a long shelf life. This is the oil you find on supermarket shelves.

For Your Small Oil Business

If you are a small business owner, perhaps with a farm or a small oil press, a batch oil refining machine is a powerful tool for you. It allows you to take the crude oil you produce and greatly increase its value. Unrefined oil has a short shelf life and can only be sold locally at a low price. By refining it, you create a stable product that can be bottled and sold in local stores for a much higher profit. Our small-scale batch systems are designed to be affordable and easy to operate. You do not need to be a chemical engineer to use them. They give you the power to control your product quality and build your own brand.

For Your Large Food Corporation

If you are a large food manufacturer, your needs are different. You need massive volumes of oil with absolute consistency. The oil used in your cookies today must be identical to the oil used next month. For you, we design and build large, fully automated continuous oil refining machines. These systems are the heart of a complete oil mill plant. They run 24/7 with minimal operator input.

Our focus for your business is on maximizing efficiency. This means reducing energy consumption, minimizing oil loss, and ensuring the final product meets strict international food safety standards. These machines are a critical part of the global food supply chain.

Refiners for sale: Frequently Asked Questions

Question 1: What is the main purpose of an oil refining machine?

The main purpose of an oil refining machine is to purify crude vegetable or animal oil. It removes impurities like free fatty acids (FFAs), gums, pigments (color), and odors. This process creates a stable, high-quality oil that is suitable for cooking, food manufacturing, or other industrial applications.

Question 2: Can one refining machine be used for different types of oil?

Yes, especially our batch refining systems. They are very flexible. You can use the same machine to refine sunflower oil, soybean oil, peanut oil, and many others. We just help you adjust the process parameters like temperature and chemical dosage for each different type of oil to get the best results.

Question 3: Is refining necessary for all cooking oils?

Not all, but most of them. Oils sold for high-temperature cooking like frying need refining to improve their stability and smoke point. Some ‘cold-pressed’ or ‘virgin’ oils are not refined to keep their natural flavor, but they have a shorter shelf life and are not suitable for all cooking methods. Refining makes oil more versatile and last longer.

Summary and Recommendation

The scope of use for an oil refining machine is incredibly broad and diverse. While its most common application is producing edible oil for the food industry, its role is just as critical in other major sectors. It is a key piece of equipment for creating clean feedstock for the biofuel industry. It is essential for producing the pure, neutral oils required by the cosmetics industry. It is also a vital tool for creating specialized oils for various industrial products.

At Fude Machinery, we understand this wide scope. We have the experience to design and build a refining solution for any of these applications, at any scale.

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business