How do high-precision refining machines achieve optimal oil quality?

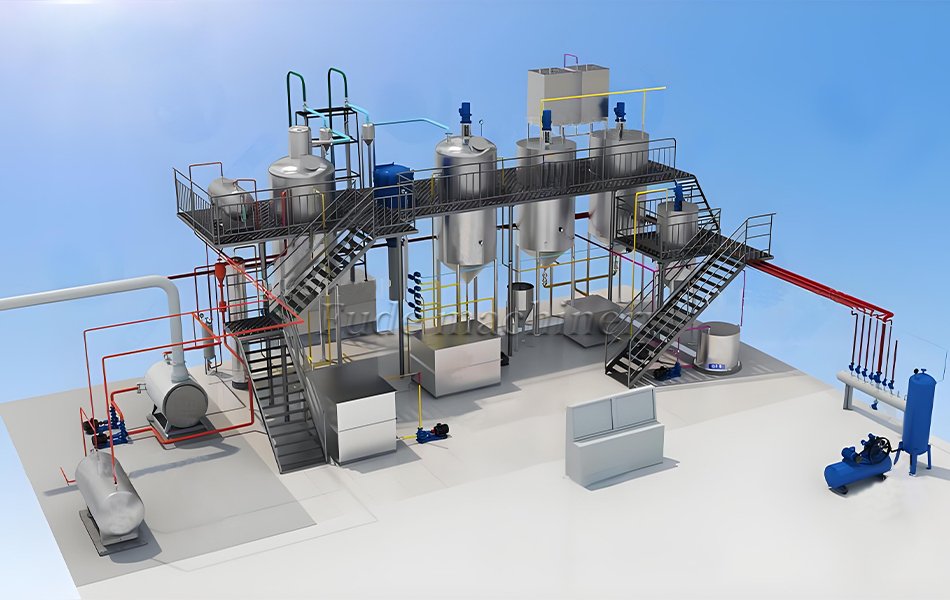

Are you seeking to produce top-quality edible oils? Do you want to ensure your refining process is efficient and precise? I am Fude Machinery. My company specializes in oil processing equipment. I understand the demand for excellence. A high-precision refining machine setup is essential for achieving superior oil quality. This includes purity, flavor, and stability.

What Pre-Treatment Units Ensure Crude Oil Purity?

High-quality edible oil starts with efficient pre-treatment — a critical step to remove crude oil impurities, ensuring smooth refining and top-tier final products.

Our precision-engineered pre-treatment units target phospholipids, gums and FFAs: phospholipids and gums cause haze and off-flavors, while FFAs reduce oil stability and smoke point. Equipped with chemical/physical degumming and neutralization functions, these units prep oil for subsequent decolorization and deodorization.

Poor pre-treatment undermines later refining stages, risking oil damage, subpar quality and higher costs. All our units integrate seamlessly for a cohesive, high-efficiency pre-treatment process.

Why is Effective Degumming Crucial for Quality?

Effective degumming is a critical step in high-precision oil refining, directly impacting the quality and stability of the final product.

It removes phospholipids and mucilaginous substances from crude oil. Left untreated, these “gums” cause oil darkening, haze, accelerated oxidation (shortening shelf life), and interfere with subsequent processes—absorbing bleaching earth and fouling heat exchangers, reducing efficiency.

Our degumming units use precise water/acid control and optimized mixing to maximize gum removal while minimizing oil loss, laying the groundwork for stable, clear, high-quality edible oil.

Practical tips and advice for you:

- Precise water dosage in degumming avoids oil loss or residual gums

- Optimal pH for acid degumming boosts phospholipid coagulation

- Regular separator cleaning prevents gum buildup and maintains efficiency

Actual Case: One of my clients processed crude soybean oil. They struggled with consistent haze in their refined product. After implementing my optimized degumming unit, their oil clarity improved by 30%. This also reduced their bleaching earth consumption in the next stage. This saved them money.

How Do Decolorization and Filtration Achieve Oil Clarity?

Post-pre-treatment oil still has pigments and suspended particles. Decolorization and filtration are key high-precision refining steps that ensure oil clarity and appearance by removing unwanted pigments, impurities, bleaching agents, and fine particles.

Our equipment optimizes oil-bleaching earth contact and separation—eliminating off-tints, haze, and impurities for a clean, bright, stable final product.

What Advanced Filtration Methods Improve Oil Purity?

Advanced filtration delivers premium oil purity and crystal clarity, surpassing basic separation methods.

High-precision refining uses pressure leaf filters (efficient impurity removal) and membrane filtration (captures fine/dissolved particles), plus final polishing filters for microscopic particle elimination. These technologies enhance oil quality, reduce filter cake oil loss, and boost yield and profitability.

Practical tips and advice for you:

- Stick to a strict filter cleaning schedule to avoid reduced flow and efficiency

- Minimize bleaching earth dosage to cut costs and oil loss

- Regularly check filter cloths/membranes—small tears damage filtration quality

Actual Case: A client processing sunflower oil experienced issues with a cloudy appearance. By upgrading to my advanced pressure leaf filters, they achieved a visual clarity improvement of 95%. This made their product more appealing to consumers.

What Deodorization Systems Remove Undesirable Odors and Flavors?

Deodorization—the final critical refining step—removes off-flavor volatile compounds for palatable edible oil. Our systems use high-temp vacuum and steam stripping to eliminate impurities, minimize oil loss, and preserve nutrients. Choose continuous (large-scale) or batch (small-capacity) models for neutral-taste, stable oil.

Why is a Reliable Vacuum System Essential for Deodorization?

A robust vacuum system is non-negotiable for deodorizer performance—it lowers volatile compound boiling points to prevent oil thermal damage, cutting energy use. Our high-precision setups maintain stable deep vacuum for efficient impurity stripping, delivering neutral-taste oil with long shelf life.

Practical tips and advice for you:

- Check vacuum system for leaks regularly—small leaks cut efficiency drastically

- Monitor steam ejectors; prevent clogging to maintain vacuum performance

- Ensure adequate cooling water for optimal vacuum condenser efficiency

Upgrading to our multi-stage ejector vacuum system slashed a client’s steam use by 20% and drastically improved oil odor and taste—solving their high energy costs and poor deodorization issues.

2026 Latest Innovations in High-Precision Refining

The edible oil refining industry keeps evolving with new tech for higher precision, efficiency, and sustainability. Staying updated is vital for competitiveness. In 2026, there’s a push for smart, green, integrated refining to cut waste and energy use, and my oil processing equipment already incorporates many such concepts.

Latest Progress One-Shot:

- AI-Driven Process Optimization: AI shifts from data analysis to real-time control, predicting optimal conditions, adjusting parameters automatically to boost yield, cut energy use, and reduce human intervention.

- Enzyme-Based Degumming and Deacidification: New enzymatic tech offers greener options, replacing harsh chemicals, reducing waste, and producing higher-quality oil with milder processing.

- Advanced Membrane Separation: Membrane tech gains traction, replacing traditional methods, saving energy, and providing higher purity without chemicals.

- Modular and Containerized Refineries: Fully containerized and modular units are popular for rapid deployment, flexibility, quick scaling, and remote operation.

Market insight: Demand grows for purer, stable, and sustainably made edible oils, with consumers willing to pay more. This pushes manufacturers to invest in high-precision refining tech to meet strict standards and stay profitable in a changing global market.

Frequently Asked Questions

Question 1: What’s key for oil purity?

The deodorizer is crucial. It removes volatile compounds causing bad odors/flavors and aids deacidification. A well-built deodorizer with a strong vacuum ensures high-quality, neutral, stable oil.

Question 2: How does Fude Machinery ensure precision in refining equipment?

Fude uses high-quality materials, advanced manufacturing, precise temp control, efficient separation tech, and PLC automation for real-time monitoring, ensuring consistent accuracy.

Question 3: Can I upgrade my existing refining setup with high-precision parts?

Yes, modular solutions allow adding advanced filters, efficient deodorizers, or upgraded controls. Our team can assess and recommend tailored upgrades to boost efficiency and quality.

Question 4: What maintenance is needed for high-precision refining machines?

Regular planned maintenance, like cleaning, leak checks, sensor calibration, and pump/filter inspections, is needed. Follow provided schedules for optimal performance and to prevent downtime. Our team offers after-sales support.

Question 5: How do these parts make oil refining cost-effective?

They improve efficiency and reduce waste. High-precision separation cuts oil loss, energy-efficient systems lower bills, and automation prevents errors, optimizing resources for maximum yield and profit.

Summary and Recommendations

Building a high-precision refining setup demands focus on key components, each crucial for oil purity, clarity, and stability. Investing in quality gear and smart design boosts efficiency and ensures consistent quality. Opt for integrated solutions blending solid mechanical design with advanced automation. Partner with Fude Machinery for comprehensive support, industry know-how, and high-performance equipment, ensuring lasting superior results.

About Fude Machinery

I am Zhengzhou Fude Machinery. I am a professional oil processing equipment manufacturer in China. I specialize in the research and production of various oil extraction machines. I focus on B2B business. My products are mainly used for food oil, refined oil, and other oil applications. My facilities are well-equipped. I ensure excellent quality control at all stages. I export my products to over 120 countries. I am committed to complete customer satisfaction.

Are you ready to elevate your oil quality with a high-precision refining machine setup?

Contact Fude Machinery’s expert team today. Get a custom solution designed just for your business. Let us help you achieve your production goals.

Related recommendations

-

What is the purpose of an oil press

738Oil press is a type of oil processing machinery that extracts vegetable oil by squeezing pre treated oil. The spiral oil press used as a pre press machine is used to pre press the oil material under high pressure, and the pre pressed bad cake is ...

View details -

Do you have any requirements for tea seeds for the tea seed peeling machine

423The requirements of the tea seed sheller for tea seeds mainly include maturity, dryness, cleanliness, consistency of specifications, and storage status

View details -

What are the components of the spiral oil press body

583The main body of the spiral oil press is composed of key parts such as the press chamber, spiral shaft, feeding hopper, cake calibration mechanism, gearbox, and motor

View details -

Can the oil extracted by hydraulic press be consumed

638The oil extracted by hydraulic press is theoretically edible, but the prerequisite is that the raw material quality is qualified, the oil extraction process is standardized, and the subsequent processing is appropriate

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business