How is Sunflower Oil Processed?

Sunflower oil is one of the most popular cooking oils in the world. It is light, healthy, and versatile. For anyone looking to enter the edible oil business, a sunflower oil production line is a very smart investment. But how do you turn a simple seed into a bottle of golden oil?

We are Fude Machinery. We are a direct manufacturer specializing in equipment for sunflower oil processing. We have helped businesses of all sizes, from small farms to large industrial plants, set up profitable operations. This guide will walk you through the entire process, step by step, and show you how it’s done.

Table of Contents

- Why is Seed Preparation So Critical in Sunflower Oil Processing?

- How does an oil press extract seed oil?

- What’s the Final Step for High-Quality Sunflower Oil?

- Oil presses can process oilseeds

- oil spiller machine:Frequently Asked Questions

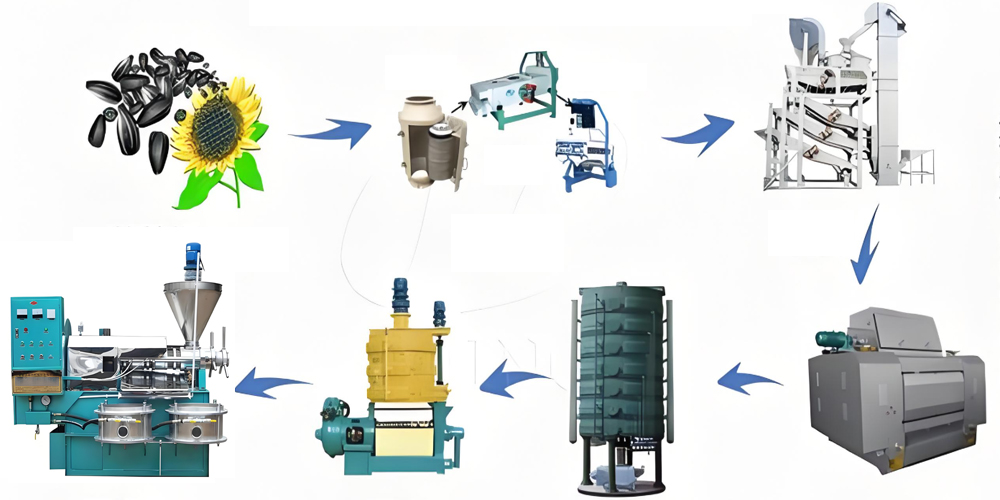

Why is Seed Preparation So Critical in Sunflower Oil Processing?

Proper seed preparation is the most important stage for maximizing oil yield and protecting your machines. You cannot simply take sunflower seeds from a silo and put them into a press. They need to be prepared correctly. This pre-treatment process ensures that you get the most oil out of every seed and prevents costly damage to your equipment. We design our pre-treatment machines to be tough and effective because we know this is where the foundation for a profitable business is built.

Every step in pre-treatment has a purpose. The goal is to get rid of useless material, like dirt and shells. Then you must break open the valuable part, the kernel, and prepare it to release its oil easily. Skipping or doing these steps poorly is a common mistake for beginners. It results in a lower oil yield, lower quality oil, and a shorter life for your expensive sunflower oil machine. This stage is not an option. It is the essential first chapter in the story of turning seeds into profit.

Step 1: Cleaning and Shelling (Dehulling)

The journey begins with cleaning. The raw sunflower seeds will have impurities like dust, leaves, sand, and small stones. We use a vibrating screen and a destoner to remove these. This is important to protect the machines that come later. After cleaning comes the single most important step for sunflowers: shelling, also called dehulling. The black shell of a sunflower seed contains almost no oil. It is also very hard and abrasive. If you try to press seeds with the shells on, two bad things will happen. The shells will act like a sponge and absorb a lot of the good oil from the kernels, reducing your yield. Also, the hard shells will cause very fast wear and tear on the screw and other parts of your oil press, leading to frequent and expensive repairs. So, you must use a special sunflower seed shelling machine to crack the shells and a separator to blow the light shells away.

Step 2: Flaking and Cooking

After shelling, you are left with the pure sunflower kernels. These kernels are then sent to a flaking machine. This machine uses large steel rollers to squeeze the kernels into thin flakes, usually about 0.3-0.4mm thick. Why do this? It’s about surface area. A whole kernel is a solid lump. By turning it into a thin flake, you drastically increase the surface area. This breaks the oilseed’s cell walls and makes it much easier for the oil to escape during the pressing stage. After flaking, the flakes are moved to a cooker or roaster. This machine uses steam or hot air to heat the flakes to a specific temperature (around 90-110°C). This cooking process serves three functions. It adjusts the moisture to the perfect level for pressing. It further breaks down the oil cells. And it reduces the viscosity of the oil, making it flow out more easily.

How does an oil press extract seed oil?

You can get the oil out of prepared sunflower flakes using mechanical pressing or a combination of pre-pressing and solvent extraction. This choice is the most important decision you will make. It depends almost entirely on the scale of your operation.

For a small or medium-sized oil mill, a screw oil press is the perfect solution. It is a straightforward, mechanical process. For a large, industrial-scale plant that processes hundreds of tons per day, a two-step method involving both pressing and solvent extraction is the industry standard. It is more complex, but it is far more efficient at a large scale.

As a manufacturer of complete oil mill plants, we provide both solutions. We help our clients choose the right technology for their business goals and budget. The single pressing method is less expensive to set up and simpler to operate. The pre-press and solvent extraction method requires a larger investment but gives you the highest possible oil yield, which means more profit in the long run for high-capacity operations.

| Extraction Method | Best For | Oil Yield | Initial Investment | What This Means for Your Business |

|---|---|---|---|---|

| Single Pressing | Small & Medium Mills (1-50 TPD) | Good (Leaves 6-8% oil in cake) | Lower | The most common and cost-effective choice for new ventures and smaller producers. |

| Pre-Press + Solvent | Large Industrial Plants (>50 TPD) | Highest (Leaves <1% oil in meal) | Higher | The standard for major producers who need maximum efficiency and yield to be competitive. |

The Single Pressing Method

This is the most common method for most small and medium-sized businesses getting into sunflower oil processing. The prepared sunflower flakes are fed directly into a powerful screw oil press. The machine uses a large, rotating screw inside a barrel to create immense pressure. This pressure physically squeezes the oil out of the flakes. The crude oil flows out through small openings in the barrel, while the solid, de-oiled material, called sunflower cake, is pushed out at the end. It’s a simple, robust, and effective method. The resulting sunflower cake is still very valuable because it contains a good amount of protein and some residual oil, making it an excellent animal feed.

The Pre-Press + Solvent Extraction Method

This method is for the big players. In this setup, the prepared flakes first go through a screw press, but this press is set to a lower pressure. It only removes some of the oil, maybe about half of it. The goal is to create a porous, partially de-oiled cake. This cake is then sent to a solvent extraction plant. Here, the cake is washed with a food-grade solvent (usually hexane). The solvent dissolves and removes the remaining oil. Later, the solvent is evaporated from the oil and recycled completely. This two-stage process is extremely efficient. It can get over 99% of the available oil out of the seeds, leaving behind a high-protein meal with very little oil. This maximum yield is essential for profitability at an industrial scale.

What’s the Final Step for High-Quality Sunflower Oil?

The final stage is refining, which turns the crude oil into a clear, stable, and appealing final product. The oil that comes from the press or extractor is called crude sunflower oil. It is dark, it contains impurities, and it has a strong flavor. You need to clean it up before it can be sold in a supermarket. The refining process is a series of purification steps. We build complete oil refinery equipment that handles this entire process to ensure a premium final product. For sunflower oil, there is one special step that is very important.

Refining machine operating steps:

- Degumming: Removes gums (phospholipids) that make the oil cloudy.

- Neutralizing: Removes free fatty acids that give the oil a bad taste and make it spoil quickly.

- Bleaching: Uses a special clay to absorb dark color pigments, making the oil lighter.

- Deodorizing: Uses steam under vacuum to remove any remaining unwanted smells and flavors.

- Winterization (Dewaxing): This is the special, critical step for sunflower oil. Sunflower oil naturally contains waxes from the seed coat. If you do not remove them, the oil will become thick and cloudy when it gets cold (like in a refrigerator). Winterization is the process of chilling the oil so these waxes crystallize, and then filtering them out. This ensures the final oil stays perfectly clear even at low temperatures, which is what customers expect.

Oil presses can process oilseeds

A screw oil press is a device that applies mechanical pressure to raw materials through the rotation of a screw shaft to extract oil from oilseeds. It has a wide range of applications and can process various oilseed crops and oil-containing raw materials.

- Sunflower seeds: Contain approximately 40%-50% oil, with a light oil quality and rich in unsaturated fatty acids.

- Soybeans: Contain approximately 18%-22% oil, with a high protein content. The soybean meal left after oil extraction can be used as feed or raw material for soy products.

- Peanuts: Contain approximately 45%-50% oil, with a fragrant oil quality, suitable for cold or hot pressing.

- Sesame seeds: Oil content approximately 50%-60%, with a rich aroma, suitable for small-batch precision pressing.

- Walnuts: Oil content approximately 60%-70%, with nutrient-rich oil, but oil yield varies by variety.

- Flaxseeds: Oil content approximately 35%-45%, rich in alpha-linolenic acid, suitable for cold pressing.

Technical features of cold oil press machine:

- High oil yield: 2-3% higher than old-style equipment, yielding an additional 2-6 pounds of oil per 100 pounds of peanuts.

- Energy-efficient and high-performance: Reduces power consumption by 40% for the same output, saving 30 yuan in electricity costs per day.

- Multi-stage pressing: Completely extracts oil in a single press, with residual oil content in the cake as low as 4%-8%.

- High adaptability: Can process over 30 types of oilseeds, including peanuts, soybeans, rapeseed, and walnuts.

oil spiller machine:Frequently Asked Questions

Question 1: Do I have to remove the shells from sunflower seeds before pressing?

Yes, absolutely. For successful sunflower oil processing, shelling is a critical step. The shells contain almost no oil, they cause very high wear and tear on your oil press screw, and they absorb good oil, which lowers your yield. Always remove the shells.

Question 2: What is winterization or dewaxing in sunflower oil processing?

Winterization is a special refining step to remove natural waxes from sunflower oil. If you do not remove these waxes, the oil will become cloudy and hazy when stored at cool temperatures. Dewaxing ensures your final product stays perfectly clear, which is what customers expect.

Question 3: What is the difference between single pressing and pre-pressing + solvent extraction?

Single pressing uses just a screw press to get the oil out. It is best for small to medium plants and leaves about 6-7% oil in the cake. Pre-pressing + solvent extraction is for large industrial plants. It uses a press to get some oil out, then uses a solvent to get the rest. This method is much more efficient, leaving less than 1% oil in the final meal.

Oil extraction equipment: comprehensive recommendations

The process of turning sunflower seeds into high-quality oil is a logical sequence of steps. Success in sunflower oil processing depends on mastering each stage. You must invest in thorough pre-treatment, especially shelling. You need to choose the right extraction method for your business scale. And you must include a full refining process, including the critical dewaxing step, to create a premium final product.

By working with a single, experienced manufacturer like Fude Machinery, you simplify this entire process. We provide the complete, integrated sunflower oil production line as a turnkey solution. As a factory-direct seller, we ensure you get the best technology at a competitive price.

Are you ready to start your journey in the sunflower oil business?

Contact our expert team at Fude Machinery today. We will provide a professional technical consultation and a detailed quotation for a sunflower oil production line tailored to your specific goals.

Related recommendations

-

Small oil factory production line

458Around the world, the consumption of edible oils is growing by the day. You have probably noticed that the demand for different types of oils is also increasing as people have differing tastes and uses of the same. What you may not know is that s...

View details -

Fully automatic oil press

522The fully automatic oil press is an efficient, fast, and automated device mainly used to extract oil from various plant seeds

View details -

Is olive oil produced by an oil press

506The process of extracting olive oil involves multiple steps such as picking, cleaning, crushing, pressing, separating, and filtering the olive fruit. It is recommended to use a Fude oil press to obtain high-quality olive oil products.

View details -

Is a Hydraulic Oil Press Right for Your Business?

176You are considering an investment in oil processing equipment. A key question you face is, "Is a hydraulic oil press the right choice for my business?" The answer is yes, if your goal is to produce premium, high-value oils for niche markets. A hy...

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business