How to build a small palm oil factory

As one of the world’s most widely consumed vegetable oils, palm oil’s industrial chain spans multiple sectors including food processing, biofuels, and daily chemicals. Establishing an efficient and sustainable palm oil mill requires systematic planning across the entire spectrum—from raw material supply chains and process design to equipment selection and environmental compliance. This article combines industry practices with technological trends to provide actionable guidelines for mill construction.

Preliminary Preparations for Establishing a Palm Oil Mill

Site Selection and Raw Material Supply Chain: Proximity to Resource Hubs

The shelf life of palm fruit (requiring processing within 24 hours of harvest) necessitates locating factories adjacent to oil palm plantations. Taking Southeast Asia as an example, major production areas such as Sabah, Malaysia, and Kalimantan, Indonesia, have established a “plantation-processing plant” cluster model, effectively reducing transportation losses and costs.

- Palm fruit contains approximately 20%-24% oil, with the pulp containing 18%-20% oil and the kernel containing 50%-55% oil.

- One ton of fruit bunches can yield approximately 200 kilograms of crude palm oil (CPO) and 50 kilograms of crude palm kernel oil (PKO).

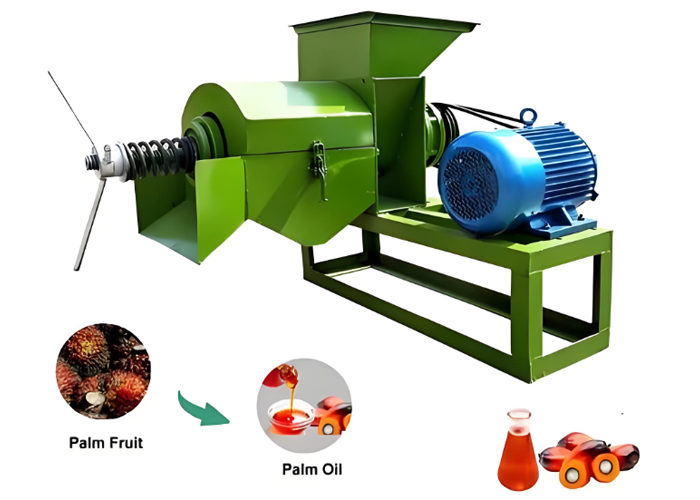

Palm Kernel Oil Press Configuration List

Palm oil production comprises three core segments: pressing, refining, and fractionation. The process route must be customized based on product positioning (e.g., edible oil, industrial oil).

- Pressing Section: From Fruit Bunch to Crude Oil

- Killing Yeast: Employing a horizontal steam sterilization tank, the process involves high-temperature steaming at 140°C for 60-90 minutes to inhibit lipase activity and prevent elevated free fatty acids (FFA).

- Dehusking: A drum-type dehulling machine separates pulp from empty husk strings through mechanical vibration, achieving a dehulling rate of ≥98%.

- Pressing: Palm kernel oil presses are the industry’s mainstream choice, offering the following advantages: continuous production capability, processing capacity of 10-100 tons per hour, and residual oil content ≤8%.

- Refining Section: Enhancing the Value-Added of Petroleum Products

- Physical Refining: Suitable for crude oils with high acid value (FFA > 5%), this process removes acids through steam distillation, thereby reducing alkaline refining wastewater discharge.

- Decolorization: The dosage of activated white clay must be dynamically adjusted based on pigment content (typically 1%-3% of oil weight), with filtration precision reaching 0.5μm.

- Customization Development Section: Customized Product Development

- By controlling crystallization conditions, stearin (melting point 50–55°C) is separated from soft fat (melting point 20–24°C) to meet diverse market demands.

- Food grade: Refined soft fats are used for frying oils, while hard fats are used for margarine.

- Industrial grade: Hard fats are used for soap and candle production, while soft fats are used as base oils for lubricants.

How to set up small scale palm oil mill

Now that you have arranged for the necessary equipment and goods it’s time to understand the process of palm oil extraction, refining and how to do the whole process.

- Reception – First of all bring the bunch of palm fruits and store them in your inventory. Palm fruits will arrive directly from your field or any market if you have imported them.

- Separation of fruits from bunches – The fruits need to be separated from the raw bunches first. Use the thresher for separating the fruits from bunches. You can do this manually by hiring some laborers to manually separate the fruits from bunches. But it is time-consuming and requires more labors. With the thresher, the process becomes time saver and simple. Just add the bunches on the machine and the rotating machine will separate the fruits from the bunches.

- Cooking the palm fruits – The next step is to boil the palm fruits at high temperatures. Heating makes the pulp softer making it easy to extract the oil. Use the boiler to cook the fruits. The boiler cooks the fruits with hot steam. However, over boiling should be avoided otherwise it will reduce the protein value of palm fruits.

- Extraction of palm oil – Now, you need to extract the oil from the pulp or mixture of boiled palm oil fruits. The equipment you will use here is palm oil presser. Make sure to purchase a good quality presser as presser is the main machine that will extract the raw palm oil from fruits. The basic principle of palm oil presser is pressure. The machine applies the pressure to extract the oil from boiled fruits.

- Filtering and refining – The extracted palm oil contains impurities and should be filtered out. Unrefined oil contains a mixture of free fatty acids, moisture, dirt, phospholipids, fibers, and pigments. Use palm oil filters and palm oil refining equipment to refine oil for sale.

- Storage – Store the oil in tanks or drums before packaging. Make sure that the tanks or drums you use for storage are covered with a protective coating. Because the iron contained in the drum metal may react with the oil. To avoid, Oxidation of oil due to storage maintain the temperature of around 50 degrees using hot water or steam coils.

- Package and dispatch – Use labor to pack the refined oil into bottles ready to dispatch. In large mills they have machines for packaging firm, at your small-scale palm oil mill; some labor is enough to do the packaging. Use your stickers on the bottles for your brand.

Features and Advantages of the Palm Kernel Oil Press

Palm oil press has multiple advantages, making it widely used in palm oil production. The following is a detailed introduction to its main advantages:

- Efficiency: The palm oil press adopts advanced spiral extrusion technology, which can efficiently extract oil from palm fruit. For example, a double helix oil press gradually reduces the outlet distance and increases the oil yield through two relatively rotating helices. In addition, the hydraulic system of the oil press can automatically adjust the pressure to ensure high oil output efficiency.

- High degree of automation: Modern palm oil presses are usually equipped with automated control systems to achieve automatic operation and monitoring of the equipment, reducing the difficulty and labor intensity of manual operation. For example, the fully automatic BTMA palm oil production line supports cold and hot pressing technology, with a residual oil rate of less than 1%, ensuring oil efficiency.

- Strong durability: The palm oil press is made of high-quality materials, such as high carbon steel, which has undergone high-frequency quenching and heat-resistant treatment. It has high hardness, strength, and good wear resistance, and is suitable for continuous operation under high temperature and high pressure. Its service life can reach several decades. In addition, vulnerable parts such as snails and strips are treated with special processes and covered with wear-resistant materials, greatly improving their service life.

- Energy saving and low consumption: Palm oil presses are designed with a focus on energy conservation and environmental protection, with an average fuel consumption of less than 15kWh per ton and significant energy savings. At the same time, environmental protection is emphasized during the operation of the equipment, reducing pollution to the environment and energy consumption.

- Low residual oil rate: Through multiple presses and optimized processes, the palm oil press can extract oil to the maximum extent possible with a low residual oil rate. For example, the residual oil rate of Guorui Oil’s palm kernel oil press is as low as 6% -7%. In addition, the physical extrusion process can maximize the retention of nutrients such as protein, fatty acids, and minerals.

- Environmental protection and energy conservation: Palm oil presses pay attention to environmental protection in the production process, reducing pollution to the environment and energy consumption. For example, the oil clarification station adopts the latest technology to minimize equipment investment and reduce oil losses while ensuring oil quality. Meanwhile, the residue and sludge generated after pressing can be used as fertilizer or fuel to achieve resource recycling.

Palm oil press has become an important equipment in palm oil production due to its high efficiency, high degree of automation, strong durability, energy saving and low consumption, strong applicability, easy operation, low residual oil rate, environmental protection and energy saving, and high investment return.

Market Outlook for Palm Oil

Food Industry: A Core Sector of Global Consumption

- Palm oil accounts for over 70% of fats used in food processing. Its semi-solid nature (melting point 33-39°C) makes it an ideal substitute for hydrogenated vegetable oils, thereby preventing the formation of trans fatty acids.

- Industrial applications account for approximately 20% of palm oil consumption, primarily leveraging its chemical stability and renewable nature.

- Palm oil undergoes sulfonation, esterification, and other reactions to produce surfactants such as sodium fatty alcohol sulfate (LAS) and fatty alcohol polyoxyethylene ether (AEO), which are widely used in daily chemical products like laundry detergent, shampoo, and dishwashing liquid.

- Palm oil-based polylactic acid (PLA) biodegradable plastic is used for food packaging and disposable tableware to reduce plastic pollution.

- Modified palm oil can be processed into bio-based lubricants for use in automotive engines, industrial machinery, and other applications. These lubricants exhibit biodegradability (degradation rate >90%) and low toxicity.

Comprehensive Recommendations

Establishing small-scale palm oil processing plants is an excellent resource for generating income. Due to the huge demand for palm oil, you can earn considerable profits in local or nearby small markets. Palm oil is widely used in various fields such as pharmaceuticals, cosmetics, and food. Therefore, if you want to establish your own project and ensure that it never loses its market, then a palm oil processing plant is a good choice.

Zhengzhou Fude Machinery Equipment Co., Ltd. is a professional enterprise engaged in the research and development, production, and sales of oil presses. We are committed to providing customers with efficient, stable, and reliable pre-sales and after-sales services. If you want to learn about the oil processing industry, please consult us.

Related recommendations

-

What are the side effects of cold pressed sesame oil

462Cold pressed sesame oil, as a type of edible oil, is generally consumed in moderation without significant side effects

View details -

What types of oil are suitable for hydraulic oil presses

540Hydraulic oil presses are suitable for a variety of oil types, especially those with high oil content, high oil quality requirements, or requiring cold pressing

View details -

What are the advantages of an oil press

771The screw oil press is a fully automatic hydraulic edible oil processing machine that uses a rotating screw shaft to continuously and efficiently extract oil from raw materials. Its core advantages lie in its compact structure, user-friendly op...

View details -

Which type of tea seed peeler is suitable for use at home

413For home use, a small, semi-automatic or manual assisted tea seed sheller that is affordable, low-noise, safe and reliable is a more suitable choice.

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business