How to Start a Palm Oil Processing Business: A Complete Guide

Starting a palm oil processing business is a fantastic opportunity, especially in growing markets. You take a perishable agricultural product, Fresh Fruit Bunches (FFB), and turn it into valuable Crude Palm Oil (CPO), a globally traded commodity. However, success is not accidental. It requires a solid plan and the right technology.

As Fude Machinery, a specialist manufacturer, we have helped hundreds of entrepreneurs just like you launch and grow their own palm oil mills. This is not just a sales page. This is our comprehensive guide, based on our experience, to walk you through every step, from the first idea to a running, profitable business.

Table of Contents

- Step 1: How Do You Create a Solid Business Plan?

- Step 2: What is the Palm Oil Processing Flow?

- Step 3: How to choose the appropriate refining equipment

- What Are the Most Important Factors for Success?

Step 1: How Do You Create a Solid Business Plan?

A strong business plan is your roadmap to success. Before you buy a single piece of equipment, you need to do your homework. This plan will guide your decisions and help you secure funding if you need it. A good plan for a palm oil processing business has three main parts. First is market research.

You must know who you will sell your CPO to. Will you sell it to large refineries, or will you sell it locally for cooking? Knowing your end customer is vital.

Second is raw material sourcing. This is the most critical part. Where will you get your Fresh Fruit Bunches (FFB)? Do you have your own plantation, or will you buy from local smallholder farmers?

The quality and consistency of your FFB supply will directly impact your mill’s performance and profitability. Finally, you need a detailed financial plan. This includes the cost of the machinery, land, buildings, and the money you will need to run the business day-to-day. A well-researched plan turns a good idea into a viable business.

Financial Planning: The Two Types of Costs

Your financial plan must be realistic. You need to understand both your initial investment and your ongoing expenses. This helps you calculate when your business will become profitable.

| Cost Type | What It Includes | Why It Matters to You |

|---|---|---|

| Capital Expenditure (CAPEX) | Land purchase, building construction, machinery costs, installation fees. | This is the large, one-time investment you need to start the business. |

| Operating Expenditure (OPEX) | FFB purchase, employee salaries, fuel for the boiler, electricity, maintenance. | These are the daily, weekly, and monthly costs to keep your mill running. |

Thinking about both types of costs will give you a full picture of the investment required. We can help you by providing a clear and detailed price list for all the necessary machinery.

Step 2: What is the Palm Oil Processing Flow?

Understanding the process is key to choosing your machines. Before you look at specific models, you need to know how palm fruit becomes oil. The process is a series of logical steps that are the same for every mill, big or small. Each step has a specific purpose and requires a specific machine to do the job. A well-designed mill arranges these machines in a sequence to create an efficient production line.

Here is the standard process flow:

- FFB Reception: Fresh Fruit Bunches arrive and are weighed.

- Sterilization: The FFB are cooked with high-pressure steam. This stops enzymes from breaking down the oil, loosens the fruit from the bunch, and softens it for pressing.

- Threshing: The fruitlets are separated from the empty bunch.

- Digesting: The fruitlets are reheated and mashed into a pulp. This breaks down the oil-bearing cells.

- Pressing: The pulp is squeezed under high pressure to extract the crude oil.

- Clarification: The extracted liquid, a mix of oil, water, and solids, is cleaned. The pure CPO is separated.

Knowing this flow helps you understand why each machine is necessary and how they work together as a system.

Step 3: How to choose the appropriate refining equipment

You choose machines based on your planned production scale. A machine that is perfect for a small village cooperative will be completely wrong for a large plantation. At Fude Machinery, we manufacture palm oil processing machines for all scales. We help you choose a solution that matches your budget and your ambition.

The main factor is “Tons Per Hour” (TPH), which means how many tons of Fresh Fruit Bunches your mill can process in one hour.

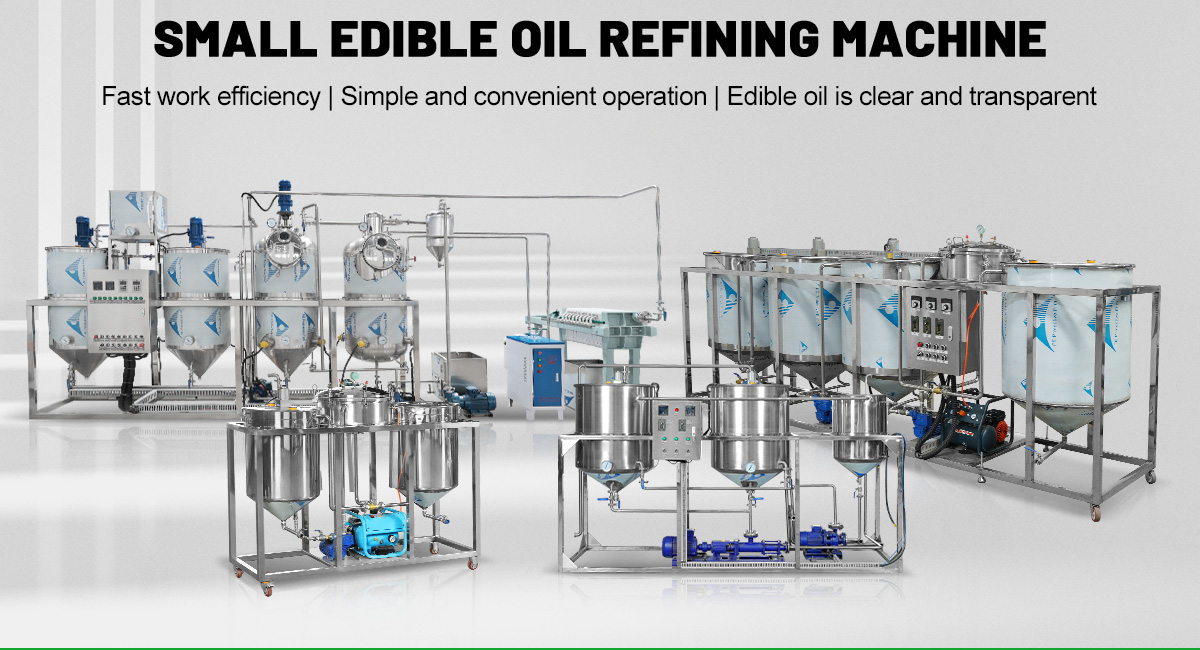

For Small-Scale Mills (1-5 TPH)

This is the most common starting point for new entrepreneurs and farming cooperatives. The goal here is affordability and simplicity. The machinery is robust, easy to operate, and requires less initial investment. A small-scale oil press machine is the heart of this setup.

- Who it’s for: Smallholders, start-ups, community projects.

- Key Machines: Simple cage sterilizer, manual or semi-automatic thresher, screw press, basic clarification tank.

- Our Advantage: We provide a complete, compact set of machines that are easy to install and maintain, allowing you to start producing oil quickly and with a lower initial risk.

For Medium-Scale Mills (10-30 TPH)

This is for the growing business. You have a reliable supply of FFB, and you need to increase your output to meet market demand. This scale introduces more automation to improve efficiency and reduce labor costs.

- Who it’s for: Established plantations, growing businesses, serious investors.

- Key Machines: Vertical sterilizers, a mechanical threshing drum, a digester, a double-screw press for higher extraction, and a more advanced clarification system with a vibrating screen.

- Our Advantage: We design these mills as a balanced system. We focus on improving your Oil Extraction Rate (OER) and ensuring the CPO quality is high and consistent. Our equipment is designed to grow with your business.

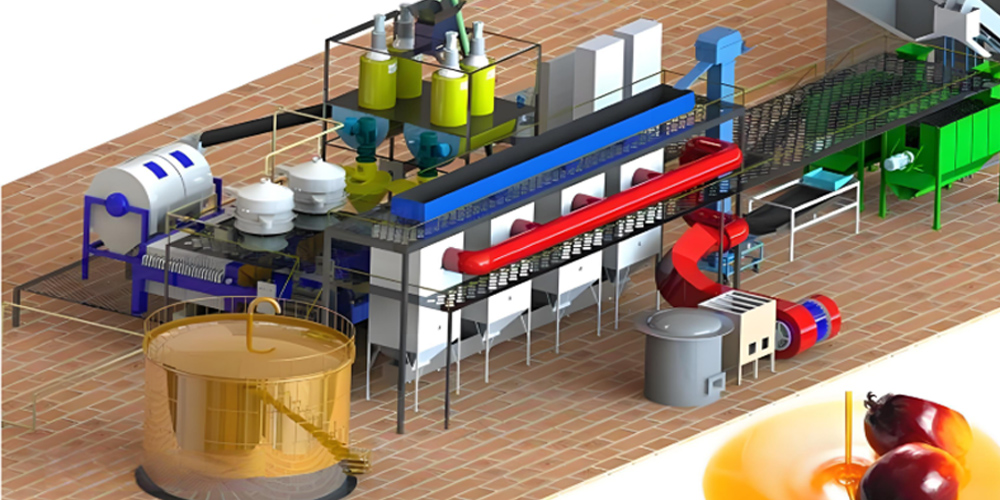

For Large-Scale Mills (45+ TPH)

This is the industrial level. These mills are for large corporations and huge plantations. The focus is on maximum efficiency, full automation, and the lowest possible operating cost per ton of oil.

- Who it’s for: Large agro-industrial companies, major CPO exporters.

- Key Machines: A fully automated system including a loading ramp, sterilization station with multiple cages, a horizontal threshing drum, continuous digesters, and a full clarification station with centrifuges and purifiers. This is a complete oil mill plant.

- Our Advantage: As an experienced manufacturer, we have the capability to design and supply these large-scale turnkey projects. We work with your engineers to plan the entire factory, from civil works to final commissioning, ensuring world-class performance.

What Are the Most Important Factors for Success?

Factor 1: Oil Extraction Rate (OER)

This is your most important number. OER is the percentage of oil you get from the fruit you process. A typical good rate is between 18% and 22%. A higher OER means more oil from the same amount of fruit, which means more profit.

The quality of our palm oil processing machine, especially the screw press, is designed to give you the highest possible OER.

Factor 2: FFB Quality (The 24-Hour Rule)

Palm fruit is highly perishable. As soon as it is harvested, enzymes start to increase the Free Fatty Acid (FFA) content. High FFA means lower quality oil. The golden rule is to process the FFB within 24 hours of harvesting. This is why having a mill close to your plantation is a huge advantage. Fresh fruit makes the best oil.

Factor 3: Your Equipment Partner

Choosing your supplier is a critical decision. You are not just buying steel; you are buying a long-term partnership. A good partner, like Fude Machinery, is a factory-direct manufacturer, not a trader.

We provide engineering support for your plant layout, guidance on installation, and reliable after-sales service for spare parts. This full-service support is essential for keeping your mill running smoothly and profitably for years to come.

Frequently Asked Questions

Question 1: How much does it cost to start a small palm oil mill?

The cost to start a small palm oil mill (around 1-2 tons per hour) varies, but the main investment is in the machinery. A basic set of machines can be quite affordable. The biggest variables are land cost and building construction. We can provide a detailed quote for the equipment once we know your exact capacity needs.

Question 2: What is the difference between CPO and PKO?

CPO is Crude Palm Oil, which is extracted from the fleshy part (mesocarp) of the palm fruit. PKO is Palm Kernel Oil, which is extracted from the nut, or kernel, at the center of the fruit. They are two different products with different uses and require separate processing lines. Most starter mills focus only on producing CPO.

Question 3: How profitable is a palm oil processing business?

A palm oil processing business can be very profitable. Profitability depends on your management of costs (like raw fruit) and maximizing your Oil Extraction Rate (OER). A well-run mill can achieve a good profit margin. The key is turning a perishable raw fruit into a stable, high-demand commodity like Crude Palm Oil.

Summary and Recommendation

Starting a palm oil processing business is a journey with huge potential rewards. The path to success is clear. You must begin with a strong business plan, thoroughly understand the production process, and choose machinery that is perfectly suited to your scale. By focusing on key factors like OER and FFB quality, and by choosing a reliable manufacturing partner, you can build a profitable and sustainable business.

Consult Fude Machinery for professional advice and a free quotation.

Related recommendations

-

How Tea Seed Oil Processing Promotes Profitability

548Seeking high-value oils? Tea seed oil demand is rising but seems complex. We clarify its potential and processing needs for your investment strategy. Tea seed oil, from Camellia seeds, is rich in oleic acid ("Oriental Olive Oil") . Its growing ...

View details -

What are the types of peanut oil presses?

570The peanut oil press is a fully automated oil processing system integrating raw material pretreatment, pressing, filtration, and refining. It converts peanuts into high-quality peanut oil meeting national standards through physical or chemical me...

View details -

How to Enhance Home or Factory Operations with a Small Screw Oil Press?

125Struggling with oil extraction space & cost? Compact screw oil extractor is an affordable solution for home/small business. It saves space, needs low investment, is easy to use, and can produce fresh, high-quality oil profitably. With demand ...

View details -

How Do Oil Presses Work? A Guide for Your Business

188How is an oil press used to extract oil? Is there any profit from oil extraction? If you happen to have doubts about oil processing business, let's explore this topic together. So, how do oil presses work? An oil press is a machine that us...

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business