How to understand peanut oil refining machines?

Are you seeking to produce premium, edible peanut oil from crude groundnut oil? Do you want to understand the machinery that makes this possible? I am Fude Machinery. My company specializes in oil processing equipment. I can help you. I design and build top-tier peanut oil refining machines. My goal is to transform raw peanut oil into a safe, delicious, and marketable product for your business.

Table of Contents

- What Exactly are Peanut Oil Refining Machines?

- Why is Refining Peanut Oil So Important for Your Business?

- What are the Essential Steps in Refining Peanut Oil?

- What Main Equipment Does Peanut Oil Refining Need?

- How Do My Machines Ensure High Quality and Efficiency?

- What Are the Benefits of Choosing Fude Machinery for Your Refining Needs?

- What are the Latest Trends in Peanut Oil Refining Machines for 2025?

- Frequently Asked Questions

- Summary and Recommendations

What Exactly are Peanut Oil Refining Machines?

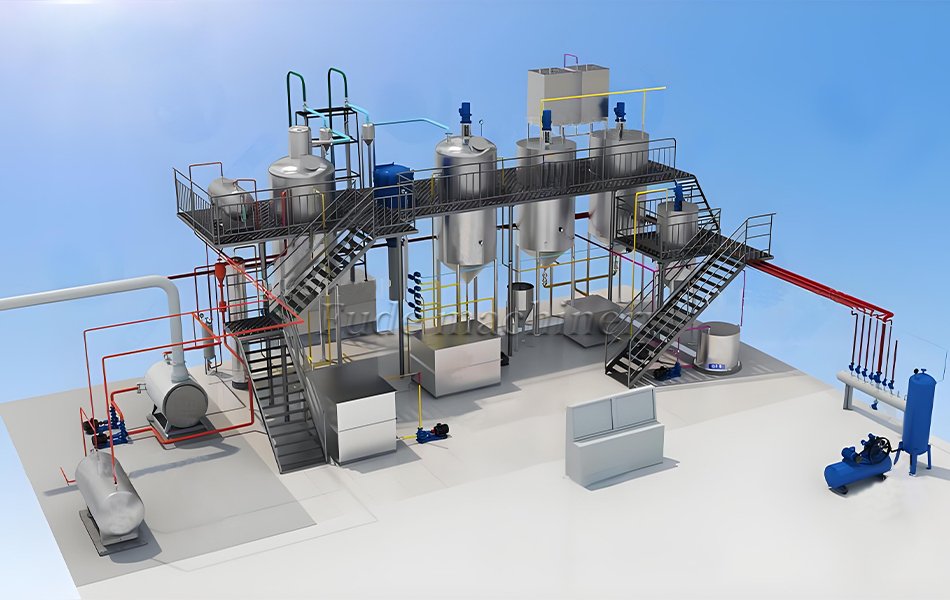

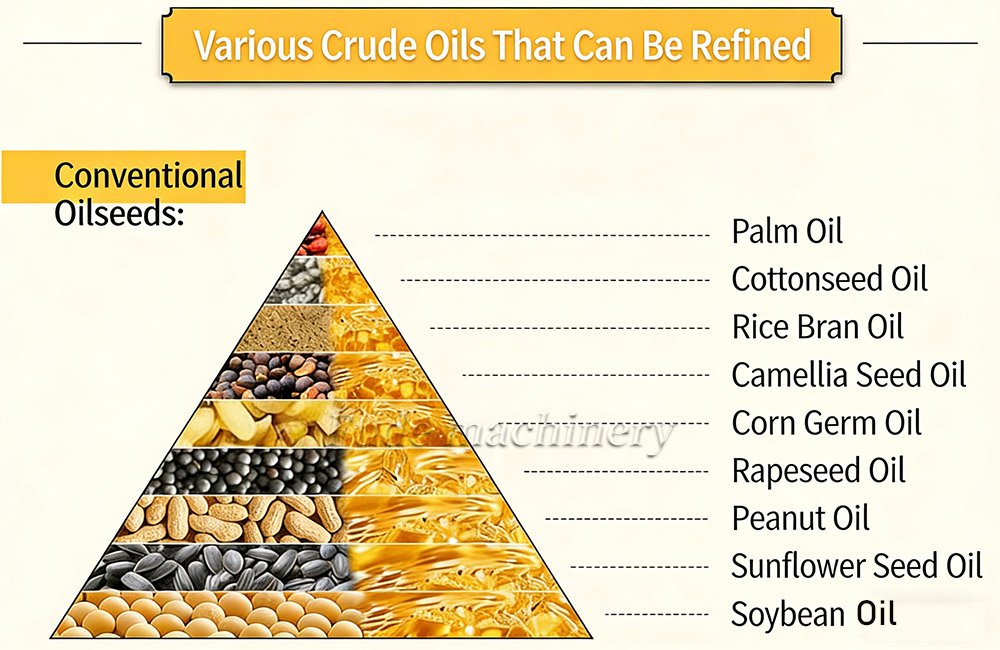

Peanut oil refining machines from Fude Machinery are specialized equipment systems designed to purify crude peanut oil (extracted directly from pressing) by removing impurities like gums, free fatty acids, pigments, waxes, and odorous compounds.

Functioning as the core of edible oil processing plants, these interconnected units transform cloudy, low-quality raw oil into clear, stable, neutral-flavored edible oil with an extended shelf life—safe and appealing for cooking and market sales. Similar to water purification, the system works through staged processes: chemical mixing, solid filtration, and vacuum heating, ensuring seamless, efficient operation.

Available in customizable capacities for small factories and large industrial plants alike, Fude’s durable, user-friendly systems minimize waste, maximize oil yield, and drive higher business profits.

Why is Refining Peanut Oil So Important for Your Business?

Refining peanut oil is a non-negotiable step for your business—it directly determines product quality, market value, and safety. Unrefined crude oil contains phospholipids, free fatty acids, pigments, and waxes that cause cloudiness, bitter tastes, short shelf lives, and limited market access (only niche industrial uses).

Investing in Fude Machinery’s peanut oil refining machines transforms crude oil into safe, palatable, visually appealing products that meet global food standards. This unlocks access to supermarkets, restaurants, and food manufacturers, boosting profit margins. Refining also extends shelf life, reduces spoilage, improves inventory management, and enhances oil versatility for fried snacks, salad dressings, and more—building your brand’s reputation for quality and reliability.

What are the Essential Steps in Refining Peanut Oil?

Understanding the essential steps in refining peanut oil helps you choose the right peanut oil refining machines. It also helps you optimize your process. Each step removes specific impurities. This improves the overall quality of the oil. I will explain these crucial steps to you.

The refining of peanut oil typically involves four main steps: degumming, deacidification, decolorization, and deodorization. Sometimes, an additional step called winterization is needed. These steps transform crude oil into high-grade edible oil. I will walk you through each one.

- Degumming: Add water/phosphoric acid to crude oil; centrifuge separates hydrated gums (byproduct: lecithin), prepping oil for further processing.

- Deacidification: Choose chemical (caustic soda neutralizes FFAs into soapstock) or physical (vacuum distillation, no chemicals) methods to lower FFAs, boost smoke point and shelf life.

- Decolorization: Mix oil with activated bleaching clay under vacuum/heat; filter presses remove pigment-laden clay for clear, bright oil.

- Deodorization: Heat oil to 220–260°C in a vacuum deodorizer; steam strips volatile odors/flavors for neutral-tasting oil.

- Winterization (Optional): Cool oil in crystallization tanks; filter out waxes for refrigeration-stable clarity, ideal for cold climates or salad dressings.

Fude’s equipment ensures minimal oil loss, efficient operation, and customizable solutions for diverse market needs.

What Main Equipment Does Peanut Oil Refining Need?

My peanut oil refining machines comprise a set of specialized equipment. These machines work together to perform each purification step. I, Fude Machinery, can provide you with all the necessary equipment. I ensure it is tailored to your capacity and budget.

The main groundnut oil refining equipment includes tanks, filters, vacuum systems, and heating units. For degumming and deacidification, you will need refining tanks. These are usually agitated tanks made of stainless steel. They allow for precise mixing of oil with water or alkali. For physical refining, a deacidification column is used. This is a tall, specialized vessel. It performs deacidification and deodorization simultaneously. Next, for decolorization, you need decolorization tanks and filter presses. The decolorization tank mixes the oil with activated clay. The filter press then separates the spent clay from the oil. This results in a lighter-colored oil. Deodorizers are crucial for removing undesirable odors. These are often high-temperature, vacuum-sealed vessels. They are designed for efficient steam stripping. A vacuum system is essential. It maintains the necessary low pressure in the deodorizer and decolorization tank. This ensures effective impurity removal and prevents oil oxidation. Lastly, heat exchangers, thermal oil furnaces or steam boilers provide the heat for the entire process. Storage tanks are also vital for holding crude and refined oil. For winterization, crystallization tanks and additional filter presses are used.

Here is a quick overview of the main peanut oil refining machines and their benefits to you:

| Equipment Type | Key Function | Your Benefit |

|---|---|---|

| Refining Tanks | Degumming, Deacidification | Removes impurities, improves oil purity |

| Decolorization Tank | Pigment Removal | Makes oil clearer and more appealing |

| Filter Press | Solid-Liquid Separation | Ensures sparkling, clean refined oil |

| Deodorizer | Odor and Flavor Removal | Produces neutral-tasting, odorless oil |

| Vacuum System | Pressure Control | Enhances refining efficiency, protects oil |

| Heating System | Temperature Management | Ensures optimal process conditions, energy control |

| Crystallization Tanks | Wax removal (winterization) | Guarantees clear oil at cold temperatures |

| Storage Tanks | Oil Storage | Manages raw and finished product inventory |

Practical tips and advice for you:

- Material Quality: Always choose equipment made from food-grade stainless steel. This prevents contamination and ensures longevity.

- Automation Level: Consider semi-automatic or fully automatic peanut oil refining machines based on your budget and labor availability. Semi-automatic is often a good balance for medium capacity.

- Energy Efficiency: Look for equipment with energy-saving designs. This includes efficient heat recovery systems and optimized vacuum pumps.

Actual case: I supplied a comprehensive refining line to a client in Ghana. He wanted to produce high-quality groundnut oil for local markets. My recommended modular semi-automatic peanut oil refining machines helped him achieve his goals. His oil quickly gained market acceptance. This led to rapid expansion.

How Do My Machines Ensure High Quality and Efficiency?

High quality and efficiency are core to Fude Machinery’s peanut oil refining machines, designed to help you produce premium edible oil at low operating costs.

Quality is guaranteed via PLC-controlled precision—accurate management of temperature, pressure, and chemical dosages minimizes human error and ensures consistent batches that meet strict food safety standards. Food-grade stainless steel construction prevents contamination for pure, market-ready oil.

Efficiency is built in: heat exchangers recycle energy, high-performance vacuum systems cut power use, and optimized centrifuges/filter presses reduce oil loss. Continuous/semi-continuous operations boost throughput and minimize downtime, lowering production costs and maximizing your profitability.

What Are the Benefits of Choosing Fude Machinery for Your Refining Needs?

Choose Fude Machinery for your peanut oil refining machines and gain a trusted partner delivering complete, customized solutions. We offer a full range of equipment—from pre-treatment to packaging, plus turnkey production lines for all capacities—eliminating the hassle of multi-vendor coordination. Our expert team tailors systems to your raw material, capacity, and space needs.

As a direct manufacturer, we provide factory-direct pricing with no quality compromises. We also offer full-service support: consultation, design, installation, training, and after-sales maintenance. With exports to 120+ countries and ongoing R&D innovation, we equip you to build a profitable, sustainable edible oil business.

What are the Latest Trends in Peanut Oil Refining Machines for 2025?

The peanut oil refining machines industry is always evolving. New technologies and market demands shape its future. Staying informed about these trends can give your business a competitive edge in 2025.

Latest developments at a glance:

- Increased Automation & Smart Control:PLC-based systems and remote monitoring cut labor, boost precision, ensure consistent quality, lower errors and raise operational efficiency.

- Enhanced Energy Efficiency & Sustainability:Upgraded equipment with efficient heat recovery and optimized vacuum pumps reduces energy use. Improved byproduct management and waste reduction help meet environmental regulations.

- Modular & Compact Designs:Modular refining units are easy to install/transport and space-saving, ideal for limited factory areas or flexible expansion. They lower infrastructure investment for small-to-medium operations.

- Advanced Wax Removal Technologies:Efficient winterization tech caters to demand for clear oils in cold climates, shortening processing time, minimizing oil loss, and keeping peanut oil bright and transparent.

Global edible oil demand is rising, fueled by population growth and dietary shifts. Peanut oil’s popularity ensures a stable refined oil market. Developing countries need cost-effective medium-scale peanut oil refining machines, enabling local producers to meet demand and creating great investment opportunities. Consumer preference for clear, stable oils also drives demand for refining technologies like winterization.

Frequently Asked Questions

Q1: Why is it important to refine peanut oil?

Peanut oil refining removes impurities (phospholipids, free fatty acids, pigments, off-odors), making oil clear, stable, safe, better-tasting and longer-lasting. It meets food safety standards, expands market access (food manufacturers, international buyers) and boosts product value & appeal.

Q2: What capacity of peanut oil refining machines does Fude Machinery offer?

Fude Machinery provides a full range of peanut oil refining machines: small batch systems (for startups/special needs) and large continuous production lines (for industrial use). Customized designs are available to match your exact daily output requirements.

Q3: Are Fude Machinery’s peanut oil refining machines easy to operate for new users?

Yes. Fude’s peanut oil refining machines feature semi-automatic/automated controls for simplified operation. We also provide full staff training on operation and daily maintenance, ensuring efficient, safe use even for refining novices.

Q4: How does Fude Machinery ensure the quality of its peanut oil refining equipment?

Quality is Fude’s top priority. We use high-grade materials (food-grade stainless steel for oil-contacting parts) and enforce strict QC across production. Our professional R&D team ensures robust, high-performance designs that meet international standards. Global export to 120+ countries attests to our quality commitment.

Q5: What maintenance is required for peanut oil refining machines?

Regular maintenance ensures optimal performance and longevity: daily checks, weekly lubrication of moving parts, monthly seal/filter inspections, frequent tank/pipeline cleaning (to prevent residue buildup), and annual overhauls (electrical checks, worn part replacement). Fude provides full maintenance manuals and training to support routine care.

Summary and Recommendations

Understanding peanut oil refining machines is the first step to producing high-quality edible groundnut oil. As a comprehensive system, it removes impurities and turns crude oil into a valuable product—critical for quality, market value and safety. Fude Machinery’s units deliver efficiency and quality via precise control and robust design.

Assess your processing capacity, budget and target oil quality first, then partner with trusted Fude Machinery. We offer customized solutions, full-service support and competitive pricing, providing you with reliable, high-performance oil processing equipment to thrive in the edible oil market.

Are you ready to elevate your peanut oil production with advanced refining machinery?

Contact Fude Machinery’s expert team today. Get a custom solution designed just for your business. Let us help you achieve your production goals.

Related recommendations

-

Is olive oil produced by an oil press

506The process of extracting olive oil involves multiple steps such as picking, cleaning, crushing, pressing, separating, and filtering the olive fruit. It is recommended to use a Fude oil press to obtain high-quality olive oil products.

View details -

Latest price of Korean hydraulic oil press 2024

670Korean hydraulic oil press is a device that uses hydraulic technology to extract oil from oil. It combines hydraulic transmission, electrical control, and other technologies, and has the characteristics of high efficiency, energy saving, and high...

View details -

Fully automatic oil press

522The fully automatic oil press is an efficient, fast, and automated device mainly used to extract oil from various plant seeds

View details -

How to extract oil from palm fruit

473Palm oil screw press is an efficient and stable oil extraction equipment

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business