Introduction to multifunctional oil press

Spiral oil press is a multifunctional equipment with the following characteristics: simple structure, small volume, easy maintenance, diverse oil pressing materials, high oil yield, large production capacity, and continuous processing.

Table of Contents

- Introduction to the internal structure of the oil press

- Why is the oil extraction rate of the oil press high

- Reference parameter table of oil press

- What raw materials can an oil press extract?

- Why choose Fude oil press

Introduction to the internal structure of the oil press

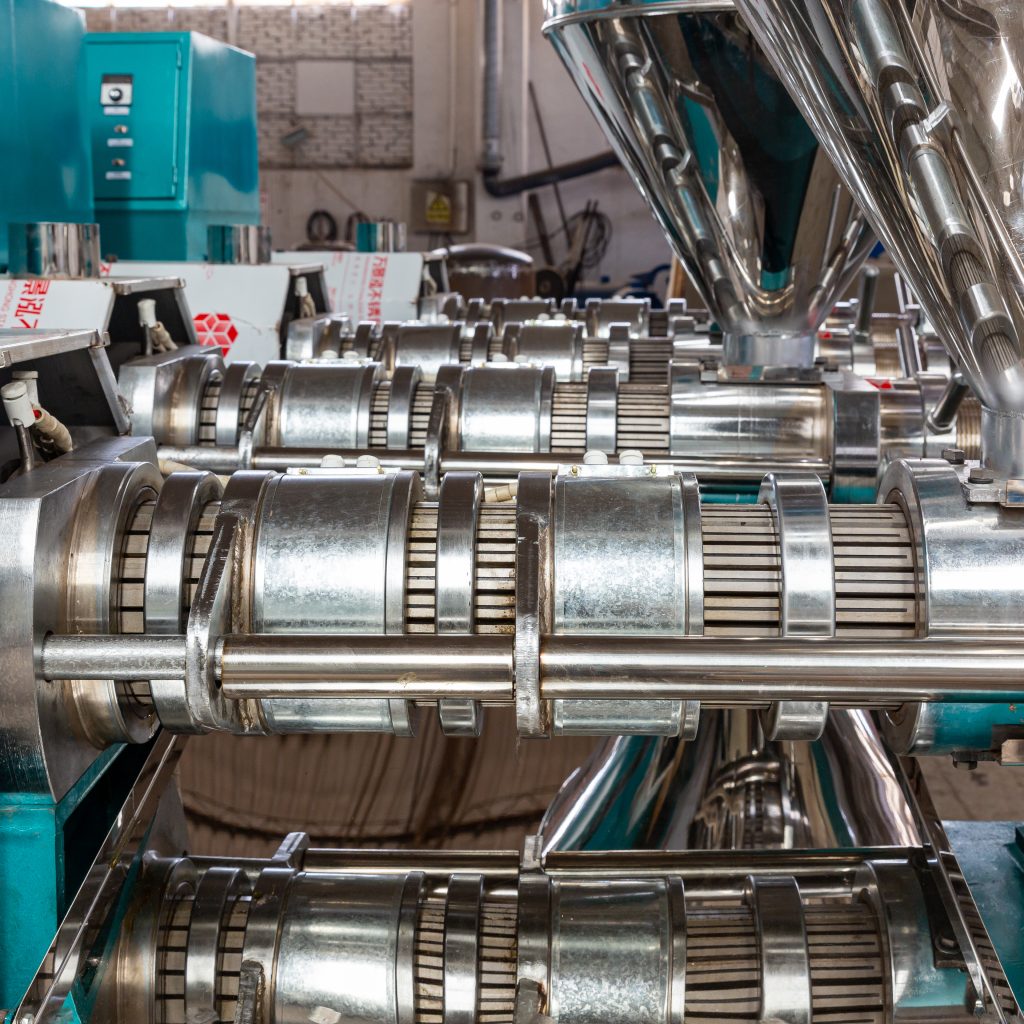

Squeezing chamber: This is the core part of a spiral oil press, consisting of a screw shaft and a cylindrical pressing cage. Squeezing can be divided into two forms: single-stage pressing and two-stage pressing.

Feeding device: The function of this part is to transport oil into the pressing chamber.

Spiral total length: This is the main component that drives the billet inside the extrusion cage.

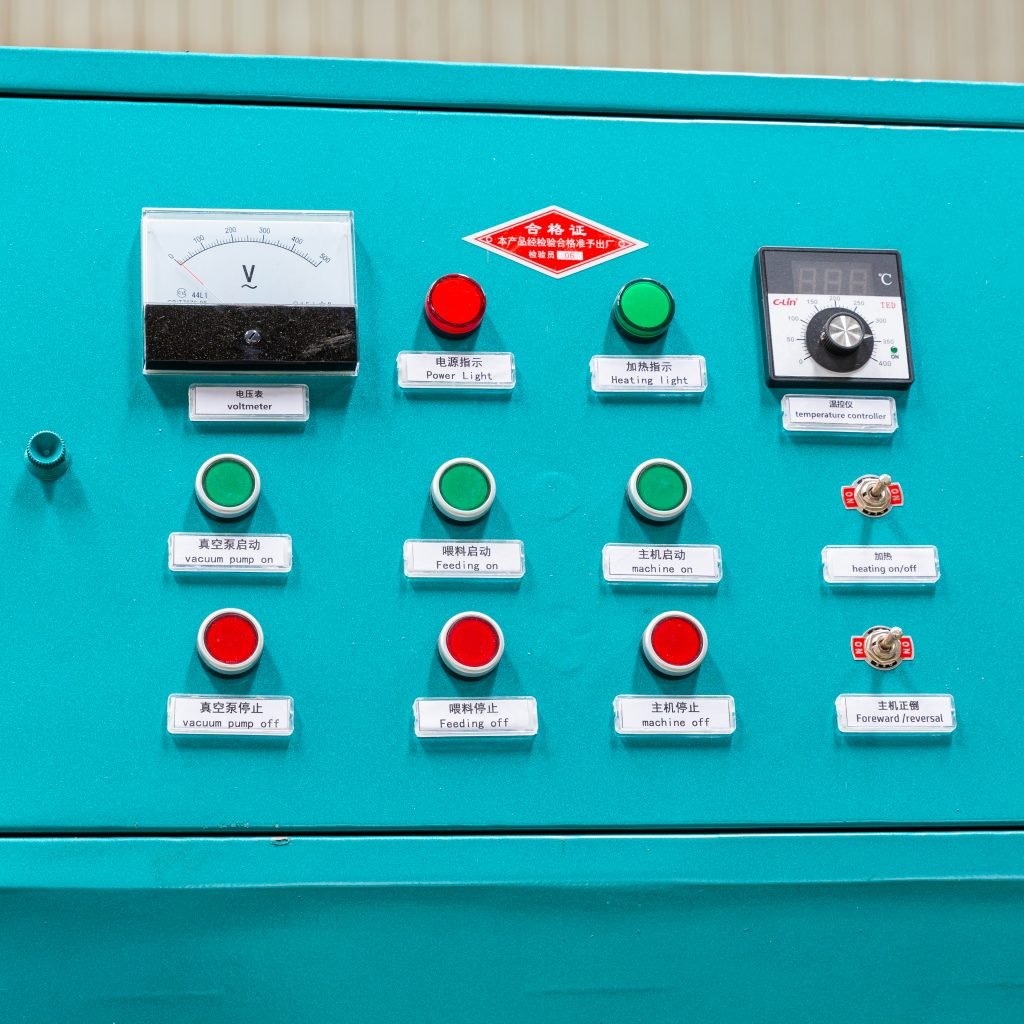

Gearbox and motor: These parts form the power system of the screw oil press, providing power to drive various parts of the oil press.

The screw oil press uses a spiral shaft to push the billet inside the extrusion cage, squeezing it into a cake shape to obtain oil, which then precipitates from the cake like material. This process is carried out under high temperature and high pressure, where the volume of the oil material continuously shrinks and is processed into a cake shape. Oil and grease then precipitate from the oil material, and the residual oil rate of the pressed cake is usually within 5%.

Why is the oil extraction rate of the oil press high

The industrial oil press adopts a continuous pressing method, which can maintain stable pressure in the pressing chamber and thereby improve the oil yield.

The oil press performs high-temperature and high-pressure treatment on the oil material in the pressing chamber, which can fully squeeze and extract the oil.

The equipment has a high-precision spiral shaft and a pressing chamber, which can ensure stable pressure and oil output rate inside the pressing chamber.

When processing different oil materials, the oil yield can be optimized by adjusting the parameters of the pressing chamber and spiral shaft.

Reference parameter table of oil press

| Oil press model | 70 type | 80 type | 100 type |

| Squeezing screw speed | 48r/min | 47r/min | 38r/min |

| Squeezing screw speed | 3kw | 5.5kw | 7.5kw |

| Processing capacity | 50-80kg/h | 65-130kg/h | 140-280kg/h |

| Overall weight | 280kg | 780kg | 1100kg |

What raw materials can an oil press extract?

Hydraulic presses are widely used in food processing, agriculture, and industry.

- Small household use: Process common oilseeds such as soybeans, peanuts, rapeseed, and sunflower seeds to meet the needs of families or communities.

- Commercial production enhancement: Centralized pressing of cottonseeds, sunflower seeds, etc., to achieve efficient resource utilization.

- Food processing factory: Produces high-end edible oils such as walnut oil and flaxseed oil, requiring cold pressing technology.

- Industrial field: Special safety measures need to be configured under professional guidance for the pressing of industrial raw materials such as castor oil and tung oil.

Why choose Fude oil press

Fude Machinery, a comprehensive manufacturer specializing in the oil processing industry, integrates production and sales. With successful cooperation cases across the country, we professionally and freely configure oil press solutions for our customers, creating greater profit margins for them and receiving positive feedback.

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business