linseed oil refined

The significance of the refining machine

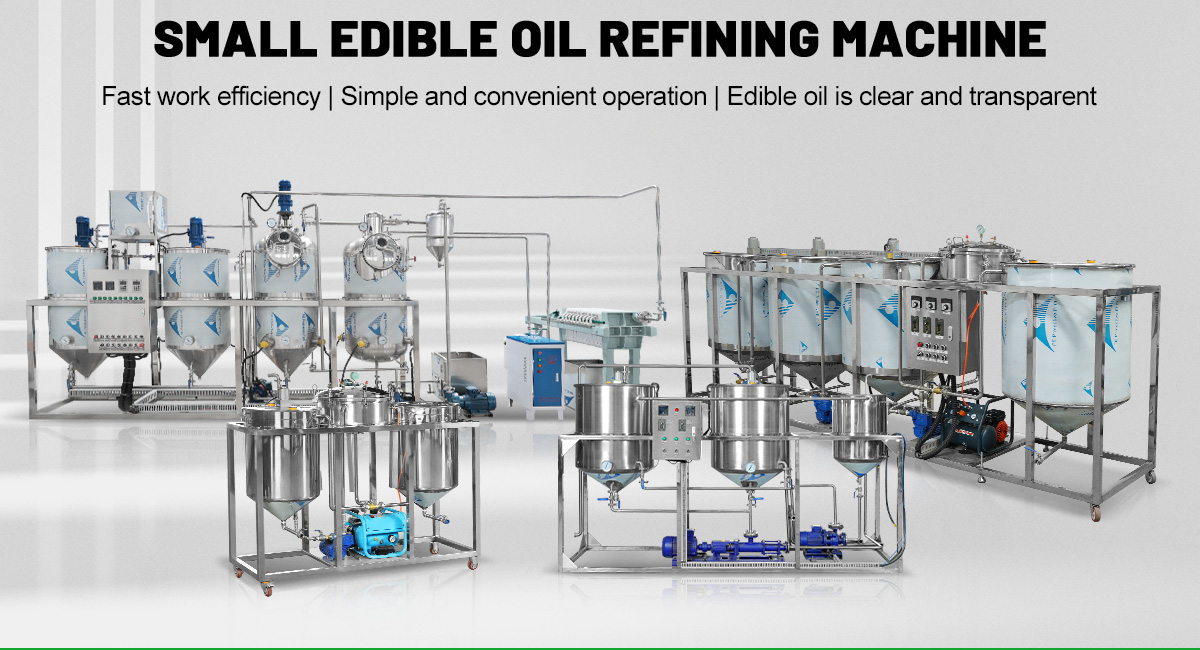

The linseed oil refining machine is a core equipment in the oil processing industry. Its function is to remove impurities from crude oil through physical or chemical methods, improve the quality of the oil, and make it meet national edible oil standards.

This equipment integrates functions such as degumming, deacidification, decolorization, and deodorization, and is suitable for small processing plants with a daily processing capacity of 1-10 tons as well as large production lines. It is an important tool for enhancing the market competitiveness of linseed oil.

Table of Contents

- The significance of the refining machine

- Why should flaxseed oil be filtered before use

- Process flow of refining equipment

- Refining machine for sale: equipment features

- The multifunctional use of refining equipment

- The advantages of rubber oil refining machine

- Refined filters: comprehensive suggestions

Why should flaxseed oil be filtered before use

Flaxseed oil is a vegetable oil extracted from flaxseeds through cold pressing or low-temperature extraction. It is rich in active ingredients such as alpha-linolenic acid (ALA, a type of Omega-3 fatty acid), lignans, and vitamin E, and possesses various health benefits.

Flaxseed oil needs to be refined before use, mainly because crude oil (unrefined crude oil) contains various components that may affect quality, safety, and eating experience. The refining process removes these impurities through physical and chemical methods, significantly improving the stability, nutritional value, and safety of the oil.

Process flow of refining equipment

- Degumming

- Using the hydration degumming method, hot water or phosphoric acid is added to the crude oil, causing the phospholipids to absorb water and swell, forming a colloidal precipitate, which is then removed through centrifugal separation. This step reduces the viscosity of the oil and enhances its clarity.

- Deacidification

- The free fatty acids (FFA) are removed through the alkali refining process. Sodium hydroxide solution is added to the oil, reacting with FFA to form soapstock and precipitate, which is then centrifuged. This step significantly improves the flavor and stability of the oil.

- Decolorize

- Under high-temperature vacuum conditions, activated clay or activated carbon is used to adsorb pigments (such as chlorophyll and carotenoids), residual colloids, and trace metal ions. The decolorized oil is clear and transparent.

- Deodorization

- In a high-temperature environment of 200-250℃ and a high vacuum setting, steam distillation is employed to eliminate volatile odor substances and residual solvents. The deodorized oil exhibits a pure aroma and a superior taste.

- Filtration and cooling

- The refined oil needs to be cooled to room temperature and passed through a fine filtration device to remove residual impurities, ensuring that the oil meets commercial sales standards.

Refining machine for sale: equipment features

- Degumming tank

- Equipped with a stirring device and a temperature control system, it ensures uniform progression of the hydration and degumming reaction.

- Deacidification tank

- Equipped with an alkali solution injection system, it can precisely control the addition of sodium hydroxide solution, avoiding excessive neutralization.

- Decolorization tank

- It adopts a vacuum sealing design to prevent oil oxidation under high temperatures; equipped with an automatic activated clay addition device to enhance operational efficiency.

- deodorizer

- The multi-layered tray structure extends the contact time between steam and oil, ensuring the full volatilization of odor substances.

- Filter

- Using stainless steel filter screens or plate and frame filter technology, tiny impurities can be efficiently removed, ensuring the clarity of the finished oil product.

- control system

- Integrated PLC automatic control module monitors parameters such as temperature, pressure, and flow in real-time to ensure process stability.

The multifunctional use of refining equipment

A refining machine is a mechanical device that removes impurities from raw materials through physical or chemical methods, thereby enhancing the purity and quality of the product. It is widely used in various industries such as rubber, oil and fat, precious metals, and chocolate. Depending on the application field and process requirements, the design, functionality, and operation of refining machines vary significantly.

Oil refining machine

- Purpose: To remove impurities such as free fatty acids, colloids, pigments, and off-odors from crude oil, and produce edible oil or industrial oil that meets standards.

- Structural Features:

- According to the processing scale, it is divided into intermittent, semi-continuous, and continuous equipment.

- The core modules include degumming tanks, deacidification tanks, decolorization towers, deodorization towers, etc., with some equipment integrating dephosphorization functions.

Rubber refining machine

- Purpose: To remove hard impurities (such as metal particles, fibers, etc.) from recycled rubber and enhance the purity of the rubber.

- Structural features:

- The surfaces of the front and rear rollers are smooth and shaped like a waist drum, which squeezes impurities from the center of the roller towards the ends during operation.

- Equipped with a cutting device, it can remove impurities accumulated at the edge of the film.

- The roller is made of vanadium-titanium alloy chilled cast iron, which has strong wear resistance; the inner cavity is processed to ensure uniform temperature.

Physical refining machine

- Principle: Separation of impurities using physical methods (such as filtration, adsorption, distillation) without altering the chemical properties of the substance.

- Applications: oil and fat decolorization (activated clay adsorption), chocolate refining (mechanical kneading), physical purification of precious metals (distillation separation).

The advantages of rubber oil refining machine

- Highly automated: Advanced control systems and automation technology are adopted to achieve automated control and data collection of the mixing process.

- Precise control of rubber composition: By controlling mixing temperature, mixing time, and adding additives, precise control of rubber composition is achieved.

- Improve production efficiency and quality: Refining machines can achieve fast and efficient mixing and processing operations, improve production efficiency and product quality, and reduce production costs.

Refined filters: comprehensive suggestions

The scope of use for an oil refining machine is incredibly broad and diverse. While its most common application is producing edible oil for the food industry, its role is just as critical in other major sectors. It is a key piece of equipment for creating clean feedstock for the biofuel industry. It is essential for producing the pure, neutral oils required by the cosmetics industry. It is also a vital tool for creating specialized oils for various industrial products.

To explore more applications for refining machines, please consult Zhengzhou Fude Machinery for professional introductions and quotations.

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business