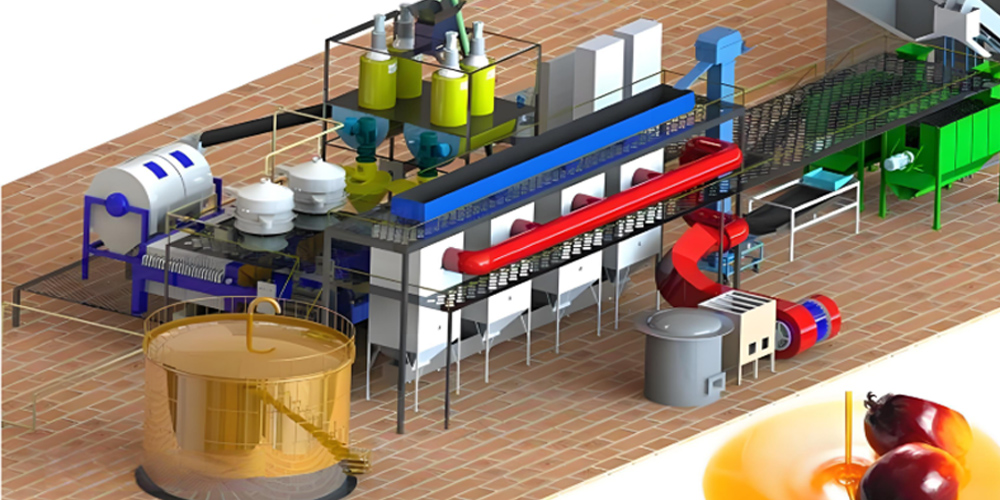

Mini Palm Oil Mill Plant

1-10 ton/d Mini Palm Oil Mill Plant

- Final Product: Red Palm Oil

- Processing Flow: Palm Fruit Threshing, Digesting & Sterilizing, Oil Pressing, Oil Filtering, Crude Red Palm Oil

- Production Capacity: 300-400 kg/h (5-10 ton/day)

- Floor Space: 15m X 6m X 5m

- Main Equipment Included: Palm Fruit Thresher, Digester (include boiler and 4 baskets), Conveying Machine, Palm Oil Press, Oil Storage Tank (with electric heating system) and Plate Filter

For mini palm oil mill plant with 1~10 ton per day production output, the processing flow is relatively simple, including threshing, digesting and sterilizing, oil pressing and oil filtering. One of the reasons why small scale palm oil mill are very common in the global market including Indonesia and Nigeria is that they are affordable and they are enough to produce sufficient amounts of palm oil for local business.

Equipment List for 10TPD Mini Palm Oil Milling Process

For 1-10 ton per day palm oil production, the crane is not equipped in most cases. The crane is used for lifting the palm fruits. In mini scale palm milling factory, this job usually done manually.

A mini production of palm oil mill basically includes belt conveyor, palm fruit thresher, screw conveyor, palm oil press, oil tank, oil filter and oil pump. Attention that not all equipment is necessary except palm oil press and filter. The equipment selection is based on your budget and business plan.

Palm oil mill plant involves the following five processing steps:

- Fruit Reception: Initially, the palm fruit bunch is weighed and offloaded from trucks. Note that the fruits have to be weighed in order to calculate the purchasing costs. The bunches have to be carefully offloaded from the trucks because if they are mishandled their quality may significantly decrease and this will have a negative effect on the final product. Poorly handled palm fruits have high acid levels which not only interfere with the taste but also increase the cost of production because the acid levels have to be decreased to a certain minimum amount.

- Threshing and Sterilizing: After that, the fruits undergo a process called Threshing where they are cut off from the bunch that holds them and they are put in boiling water with very high temperatures in order to “loosen” them. This process is what is known as — Sterilization by Pressurized Cooking. For starters, the threshing process can also be done manually to lower investment cost. (Read more about palm fruits cooker and FFB threshing machine )

- Palm Oil Extraction: The third step is the extraction of the palm oil in screw palm oil pressing machine. This is step marks the peak of processing and the oil is extracted from the fruits by pulp pressing.

- Oil Filtering: The extracted oil is then Filtered and Purified in order to remove dirt and other remains such as water and fruit shells. After the red palm oil is purified, they can be stored in barrels or gallons before they are transported to the market.

What equipment is used in palm oil processing plants to extract oil?

Palm oil processing plants use press machines to extract oil, which is the core equipment for palm oil extraction, mainly used to extract oil from palm fruits. According to different processing capabilities, there are two types of palm oil presses to choose from: single helix and double helix. Single screw presses are suitable for small palm oil processing plants, while double screw presses are suitable for large-scale production.

Palm oil press has many advantages:

- Efficient oil yield: Adopting a spiral extrusion structure and physical extrusion process, it can maximize the retention of nutrients while achieving high oil yield. For example, the oil extraction efficiency of a double helix oil press can reach over 93%, with a residual oil rate as low as 6% -7%.

- High degree of automation: Modern palm oil presses are usually equipped with automated control systems to achieve automatic operation and monitoring of the equipment, reducing the difficulty and labor intensity of manual operation.

- Strong durability: The equipment is made of high-strength carbon steel material, which has undergone high-frequency quenching and heat resistance treatment. It has high hardness, strength, and good wear resistance, and is suitable for continuous operation under high temperature and high pressure. Its service life can reach several decades.

- Energy saving and low energy consumption: Compared to traditional oil pressing methods, modern oil presses have lower energy consumption, with an average fuel consumption and electricity consumption of less than 15kWh per ton, resulting in significant energy savings.

- Multifunctionality: Some oil presses can be adapted to various raw materials, such as peanuts, soybeans, rapeseed, corn germ, etc., with strong compatibility.

- Environmental protection and energy conservation: Emphasis is placed on environmental protection and energy conservation during the processing, reducing pollution to the environment and energy consumption.

- Small investment, fast return on investment: suitable for small palm oil factories, with small investment, fast return on investment, simple installation, easy operation and maintenance.

- Strong adaptability: not limited by climate, can be exploited and operated all year round.

- Compact structure: Compact design, sturdy and stable, easy to install, and durable.

- Support customization: Different capacities of oil presses can be customized according to customer needs, with an hourly output ranging from 30-500kg.

If you plan to invest in your first palm oil factory but don’t know where to start, please feel free to contact Zhengzhou Fude Machinery and let us know your situation, and our team will provide customized solutions for your reference while maximizing project cost control.

Related recommendations

-

What are the application scenarios of refining machines

533Refining machines are used in various industries such as rubber industry, building materials industry, chemical industry, food processing industry, medicine, etc

View details -

Which model of olive oil press is recommended

661It is recommended to use a spiral oil press, which can be multifunctional for pressing vegetable oils such as olives, walnuts, corn germ, safflower seeds, seabuckthorn seeds, flaxseeds, cocoa beans, coffee beans, etc.

View details -

Can the oil extracted from the oil press be consumed directly

569It is generally not recommended to drink the oil extracted from the oil press directly. If the quality of raw materials is reliable, the oil extraction process is hygienic, and it has been properly processed and stored, the extracted oil can be us...

View details -

What are the differences between various coconut oils on the market?

589Confused by coconut oil choices? Virgin? Refined? They are not the same. Learn how they differ. Coconut oils vary mainly by processing method. Virgin oil uses minimal heat, keeping more nutrients. Refined oil uses heat and chemicals for neutral...

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business