What are the key differences between cold pressed oil and hot pressed oil?

I will explain the main differences between cold pressed oil and hot pressed oil. This information helps your business choose the right oil extraction equipment. Fude Machinery specializes in efficient oil processing solutions. My goal is to help you select the best method for your products. This ensures great quality and profit.

Last update: May 2025 | Estimated reading time: 12 minutes

Table of Contents

- How does cold pressing work, and what equipment do you need?

- How does hot pressing work, and what equipment do you need?

- What are the main differences in oil quality and yield?

- Which pressing method is right for your oil business?

- 2025 Latest trends in oil processing technologies

- Frequently asked questions

- Summary and Suggestions

- About Fude Machinery

How does cold pressing work, and what equipment do you need?

Cold pressing extracts oil without high heat. It uses mechanical pressure. The oil material is not cooked or roasted before pressing. The temperature during pressing stays below 60 degrees Celsius. In some cases, it stays even lower, around 40 degrees Celsius. This method keeps the oil’s natural nutrients. It maintains its original flavor and aroma.

When we talk about cold pressing, we are speaking about a gentle process. It uses specialized oil pressing machines You feed the raw material directly into the press. The machine then applies slow, steady pressure. This pressure squeezes the oil out of the seeds or nuts. The low heat prevents the breakdown of sensitive compounds. These compounds include vitamins, antioxidants, and fatty acids. This preservation is a key benefit. It means the oil keeps more of its health benefits. It also has a distinct, often stronger, flavor profile. Cold pressed oils are popular in health food markets. They are also used for high-value specialty oils. We design our equipment precisely for this gentle extraction. This process ensures peak oil quality.

What are the ideal materials for cold pressing?

Many different oilseeds and nuts work well for cold pressing. These include flaxseed, sesame seeds, sunflower seeds, and walnuts. Olives, coconuts, and chia seeds also produce excellent cold pressed oil. Each material has unique properties. Our machines are adaptable for diverse raw materials. This adaptability means you can process various specialty oils. This widens your product range. For example, flaxseed oil is rich in Omega-3 fatty acids. Cold pressing keeps these sensitive fats intact. Walnut oil offers a distinct nutty flavor. It also has high nutritional value. Coconut oil, when cold pressed, retains its unique tropical aroma. It keeps its beneficial medium-chain fatty acids. We can provide the right oil processing equipment for each of these. We ensure optimal results.

| Material | Cold Press Benefits | Your Business Impact |

|---|---|---|

| Flaxseed | High Omega-3 retention | Premium health oil product |

| Sesame | Rich aroma, natural flavor | Specialty cooking oil |

| Olive | Virgin quality, strong taste | High-value gourmet market |

For users:

- Material preparation: Always use clean, dry seeds. This prevents mold growth. It ensures pure oil.

- Machine temperature: Monitor your machine’s temperature. Make sure it stays low. This protects oil quality. Use a thermometer directly at the oil outlet.

- Oil storage: Store cold pressed oil in dark bottles. Keep it in a cool, dark place. This prevents oxidation and spoilage.

practical cases: A client in Africa wanted to produce premium groundnut oil. They chose our small-scale cold press machine. The oil had a rich nutty flavor. It had a long shelf life. This helped them gain market share quickly. They sold their oil at a higher price due to its quality. They expanded their business.

How does hot pressing work, and what equipment do you need?

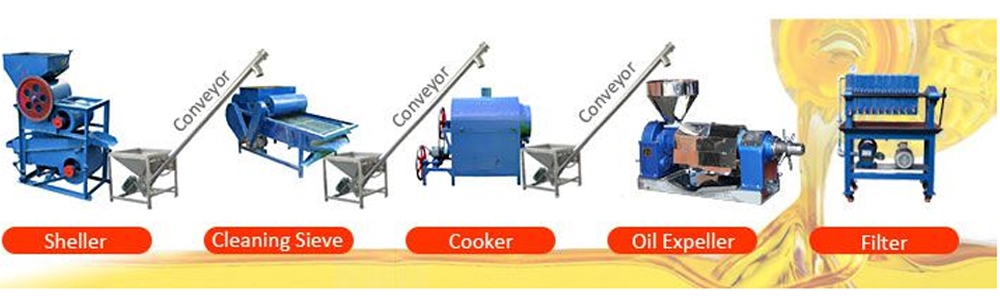

Hot pressing uses high temperatures to extract oil. The oil material is first heated. This heating can be by roasting or steaming the seeds. Then, the heated material goes into the oil press. The high temperature makes the oil flow more easily. It increases the overall oil yield significantly. This method is common for large-scale production. It is efficient and cost-effective.

When we discuss hot pressing, we prepare the seeds first. This step often involves a roasting machine or a steamer. Heating breaks down cell walls in the seeds. It also reduces the oil’s viscosity. This means more oil comes out. The oil extracted this way has a darker color. It often has a stronger, cooked aroma. Some beneficial compounds can be lost due to heat. However, the higher yield makes it a preferred choice for many businesses. This is especially true for those focusing on bulk production. It also reduces the oil remaining in the meal. The meal has lower residual oil content. This makes it more suitable for animal feed. We supply a range of hot pressing equipment. These include advanced spiral oil presses. They handle high volumes efficiently.

What are the ideal materials for hot pressing?

Many common oilseeds are suitable for hot pressing. These include soybeans, peanuts, palm kernels, and rapeseeds. Cottonseed and sunflower seeds are also often hot pressed. These materials generally have high oil content. They benefit greatly from the heating process. The heat helps release more oil from their tough structures.

Hot pressing can maximize profitability for these materials. It offers a higher yield compared to cold pressing. For example, soybean oil production almost always uses hot pressing. This ensures the maximum amount of oil extraction. Peanut oil often has a richer flavor when roasted before pressing. This hot pressed peanut oil is very popular for cooking. Rapeseed oil yields are significantly higher with preheating. This makes it economically viable for large scale operations. We help businesses choose the best equipment. This depends on their specific raw materials and production goals.

| Material | Hot Press Benefits | Your Business Impact |

|---|---|---|

| Soybean | High yield, good for large scale | Bulk edible oil production |

| Peanut | Enhanced aroma, higher yield | Popular cooking oil market |

| Palm Kernel | Maximize oil extraction | Industrial oil applications |

For users:

- Pre-heating control: Control roasting temperature carefully. Over-heating damages oil quality. It might also burn the seeds.

- Equipment maintenance: Regular cleaning of your hot press is vital. Hot oil residues can build up. This affects machine performance.

- Refining needs: Hot pressed oil often requires more refining. Plan for refinery equipment in your setup. This improves taste and shelf life.

practical cases: A large edible oil processor in Southeast Asia needed to expand. They focused on palm kernel oil. We supplied a complete hot pressing and refining line. Their production capacity increased by 30%. The higher yield boosted their profits. They praised our customized solution.

What are the main differences in oil quality and yield?

The choice between cold pressing and hot pressing directly impacts oil quality and yield. Cold pressed oil has higher nutritional value. It also keeps a stronger, more natural flavor. Hot pressed oil generally offers a much higher yield. But it may lose some delicate nutrients during heating.

Cold pressed oil is often clearer. It has lighter color. It retains more vitamins and antioxidants. These are sensitive to heat. The flavor of cold pressed oil is typically robust. It reflects the pure taste of the original seed. This makes it ideal for direct consumption. It is good for salad dressings. This oil often sells at a premium price. Its yield is lower. You get less oil from the same amount of raw material. This is because no heat helps release the oil.

Hot pressed oil is darker. It may have a cooked or roasted flavor. The heating process can degrade some heat-sensitive nutrients. This is true for Omega-3 fatty acids. However, the pre-heating treatment breaks cell walls efficiently. This allows almost all the oil to be extracted. It results in a considerably higher oil yield. Hot pressed oil is more cost-effective for large production volumes. It often requires further refining steps. These steps remove impurities. They also improve taste and stability.

| Feature | Cold Pressed Oil | Hot Pressed Oil | Practical Impact for You |

|---|---|---|---|

| Temperature | Below 60°C | Above 100°C | Affects nutrient retention and yield. |

| Nutrients | High retention of vitamins, enzymes, antioxidants | Some loss of heat-sensitive nutrients | Choose based on target market (health vs. bulk). |

| Flavor/Aroma | Natural, strong, raw | Roasted, cooked, often milder after refining | Influences cooking applications and consumer preference. |

| Color | Lighter, clearer | Darker, richer | Aesthetic appeal for end-product. |

| Yield | Lower (e.g., 60-70% of potential) | Higher (e.g., 90-95% of potential) | Direct impact on production cost and profitability. |

| Shelf Life | Shorter due to volatile compounds | Longer due to enzyme deactivation (after refining) | Important for inventory and distribution. |

| Refining Needs | Minimal or none | Often requires extensive refining | Impacts total production cost and complexity. |

| Marketing | “Natural,” “virgin,” “healthy” | “Cooking oil,” “economical” | Targets different market segments and pricing strategies. |

For users:

- Ingredient focus: If your customer values health benefits, choose cold pressing. The market for nutrient-rich oils is growing.

- Volume focus: If you need high volume and competitive pricing, hot pressing is more efficient. This is good for large retail.

- Combined approach: Some businesses use both. They produce high-value cold pressed oil. They also make bulk hot pressed oil from the same material. This maximizes profit.

practical cases: A company in Europe wanted to offer two types of sunflower oil. They produced a premium cold pressed version for specialty stores. They used the same seeds for a hot pressed, refined version for supermarkets.

They used our complete oil milling plant solution. This allowed them to diversify revenue streams. It met different market demands.

Which pressing method is right for your oil business?

Choosing the right pressing method depends on several factors. Consider your raw material type. Think about your target market. Evaluate your production scale and budget. Both methods have advantages. Your business goals guide the decision.

For instance, if you process flaxseed or chia seeds, cold pressing is usually best. These seeds have delicate oils. They easily degrade with heat. If you work with soybeans or peanuts in large volumes, hot pressing is highly efficient. It maximizes your yield. Consider your customers. Do they seek premium, natural oils? Or do they need affordable cooking oil? This helps decide. Your current facility and future expansion plans also matter. We can help design a customized solution that accounts for all these variables. This ensures you invest wisely.

Assessing Your Specific Needs

Every oil processing business is unique. Small-scale farmers might prefer simple, compact cold press machines. These machines offer ease of operation. They require lower initial investment. Large industrial groups need automated hot pressing lines. These lines handle massive quantities. They maximize output and efficiency. We provide everything from single machines to full production lines. We consider your required daily capacity. We look at your budget constraints. We also evaluate the desired oil quality and final product application. This comprehensive approach ensures you get the most suitable equipment. We help you achieve your production goals.

| Your Need | Cold Press Suitability | Hot Press Suitability | Fude Solution |

|---|---|---|---|

| Nutrient Preservation | High priority | Lower priority | Specialized cold press machines |

| High Yield, Low Cost | Less suitable | High priority | Efficient hot press lines |

| Small-scale Operation | Good fit | Less common | Compact single screw oil presses |

| Large-scale Production | Less efficient | Ideal | Continuous spiral oil presses, full plant solutions |

| Specialty Oils | Excellent choice | Not ideal | Hydraulic oil presses, small batch systems |

For users:

- Market research: Understand what your target customers value most. Is it health benefits, price, or specific flavor profiles?

- Raw material analysis: Know the oil content and properties of your seeds. This determines the most efficient extraction method.

- Long-term costs: Consider not just equipment cost. Also think about energy consumption. Factor in labor needs and refining requirements.

practical cases: A new startup in Canada aimed for organic hemp seed oil. They needed high nutrient retention. We recommended our custom-designed cold press line. It produced premium oil. This oil met all organic certifications. It quickly gained popularity in health food stores. Their business grew rapidly.

2025 Latest trends in oil processing technologies

The oil processing industry is always improving. New technologies focus on efficiency, sustainability, and flexibility. I see strong trends towards advanced automation. There is also a greater demand for multi-functional equipment. My team at Fude Machinery constantly researches these trends. We want to offer the most modern oil processing equipment.

Latest advances focus on smarter machines. These machines can adjust settings automatically. They respond to different seed types. This reduces manual labor. It improves consistency. There is also a greater push for energy efficiency. New heating and cooling systems minimize power consumption. This lowers operating costs. Environmental impact is also a key concern. Technologies minimize waste. They convert by-products into valuable resources. For example, oil cake can become animal feed. Some oil cake can even be biomass fuel.

Latest Developments Overview

- Smart Automation: Machines now have sensors and AI. They monitor the pressing process. They adjust pressure and temperature dynamically. This ensures optimal extraction. It reduces human error.

- Modular Design: New equipment is modular. You can add or change units easily. This allows for flexible production. Businesses can start small. They can expand later.

- Energy Recovery Systems: Integrated systems capture waste heat. They use it elsewhere in the plant. This significantly cuts down energy costs. It also makes operations greener.

Market insights

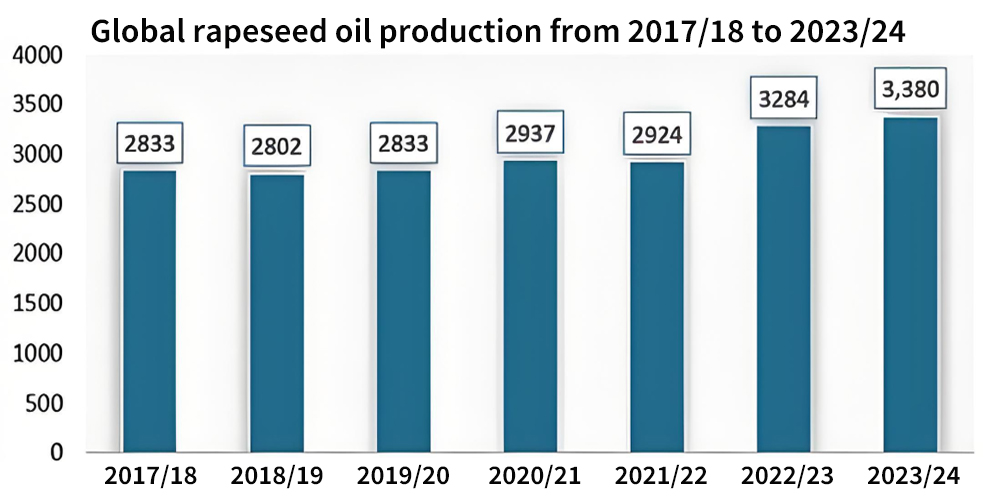

The global edible oil market is growing. Consumers increasingly demand high-quality, specialty oils. There is a strong interest in natural and organic products. This boosts the market for cold pressed oils. Simultaneously, the demand for affordable bulk cooking oils remains high. This ensures a steady market for hot pressed oils. Developing countries show increasing demand for efficient oil processing. They seek cost-effective and reliable solutions.

Sustainability is also a critical factor. Businesses now look for equipment that reduces water use. They want machines that minimize effluent. Zero-waste processing is becoming a goal. This means using all parts of the oilseed. We understand these market shifts. We design our machines to meet these evolving requirements. We help our clients stay competitive.

Frequently asked questions

Question 1: Is cold pressed oil healthier than hot pressed oil?

Cold pressed oil often retains more heat-sensitive nutrients. These nutrients include vitamins and antioxidants. Hot pressing can reduce these. So, for maximum nutrient content, cold pressed is often better.

Question 1: Can the same oil press machine do both cold and hot pressing?

Some versatile screw oil presses can do both. You adjust pre-treatment steps and operating temperatures. We offer machines designed for flexibility. This allows you to switch methods.

Question 1: How much more oil can I get from hot pressing?

Hot pressing generally yields 10-20% more oil than cold pressing. This depends on the raw material. It also depends on the efficiency of the pre-treatment. This higher yield directly impacts your profit margin.

Question 1: Does cold pressed oil need refining?

Cold pressed oil usually needs minimal refining. Sometimes it only needs simple filtration. It is often consumed in its crude form. Hot pressed oil often requires more extensive refining.

Question 1: What is the power consumption difference?

Cold pressing might consume less power for the press itself. Hot pressing requires energy for pre-heating the seeds. So, the overall energy cost can be similar or higher for hot pressing depending on the setup.

Summary and Suggestions

Understanding cold pressed oil and hot pressed oil is crucial. Cold pressing prioritizes oil quality and nutrients. It gives a lower yield. Hot pressing maximizes oil yield. It may affect some oil qualities. Your business goals and raw materials dictate the best choice. Fude Machinery offers complete solutions for both.

I recommend you assess your market. Evaluate your raw materials. Consider your budget for equipment and operations. Then, contact my team. We can provide a tailor-made plan. We ensure you make the most profitable decision. This leads to successful oil production.

About Fude Machinery

My company, Fude Machinery, is a leading Chinese manufacturer of oil processing equipment. We are based in Zhengzhou. We specialize in B2B sales. We offer high-quality equipment. These include single screw oil presses, refining machines, and roasting equipment. We also provide complete oil mill plants. My products serve food oil, refined oil, and grease processing industries globally. We have advanced production facilities. We implement strict quality control. This ensures customer satisfaction. Our products are in over 120 countries. We focus on providing efficient and cost-effective solutions. We meet diverse client needs.

For inquiries or to discuss your specific needs, please reach out to our team. We are ready to help you thrive. You can find more information on our website.

Related recommendations

-

How to Choose the Best Refining Equipment for Your Business?

142Navigating oil extraction equipment choices can be complex. We simplify your decision-making process. We help you choose the right oil extraction equipment by understanding your specific business requirements, raw material types, and desired ou...

View details -

How does the tea seed peeling machine work

449It achieves fast and efficient shelling of tea seeds and is an important equipment in the tea processing industry.

View details -

Extraction of Oil from Soya Beans

606The edible oil produced from soybeans is light, clean, and flavorful. This makes it more popular and loved by many people. Soybean oil is composed of 60% polyunsaturated fat and 24% monounsaturated fat, which combine to form a heart healthy oil....

View details -

Spiral oil press for processing corn germ oil

478Corn oilis yelow,transparent oil with has a aint smel and faint taste. ti is an easly absorbed vegetable olwhichisnot areasy.ti is qute stable when frying at a hich temperature,and can kep the color and favor ofveetables and fds without losing ...

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business