What is a Small Oil Refinery Machine?

You have an oil press, and you are producing crude oil. But you know there is more value in that oil. So, what is a small oil refinery machine? It is your most direct and affordable path to higher profits. This compact piece of oil processing equipment is specifically designed for small-scale operations. It turns your basic crude oil into a cleaner, more stable, and more valuable product. We are Fude Machinery, a B2B manufacturer. We build these machines to help businesses like yours take that important next step.

What Exactly Defines a “Small” Oil Refinery Machine?

A small oil refinery machine is defined by its compact size, its batch-based operation, and its lower daily processing capacity. It is engineered to provide the core functions of oil refining without the massive scale and cost of an industrial plant.

When we talk about a small oil refinery machine, we are talking about a system built for efficiency in a small space. Its capacity is typically measured in hundreds of kilograms per day, not tons per hour. For example, common sizes are 300kg/day or 500kg/day. It operates in batches, meaning you refine one full tank of oil at a time before starting the next. This makes the process manageable for a single operator. Most importantly, its design is simplified. It usually consists of two or three tanks and is built on a single, compact frame. This means it can fit into a small workshop or even a large garage, making it accessible for businesses without a large factory.

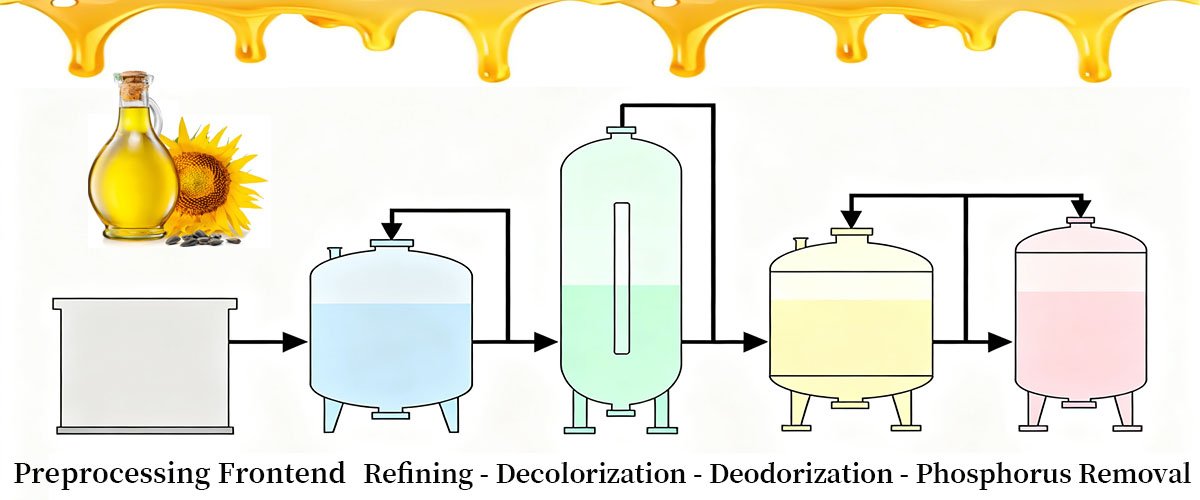

How Does This Mini Oil Refinery Work for You?

This mini oil refinery works by guiding your crude oil through a simplified, multi-step purification process. It is a hands-on system that gives you full control. We design these machines to be user-friendly, so you can easily produce better oil.

The most common design for a small oil refinery machine is the 2-tank model. This setup is incredibly efficient for small batches. It combines the first two critical refining steps into one tank, and then uses a second tank for the final purification step. This smart design saves space, reduces cost, and simplifies the operation for you. You will be able to manage the entire process from start to finish.

Step 1: Combined Purification in Tank 1

You will start by pumping your crude oil into the first tank. This tank does two jobs. First, you will perform degumming by adding hot water to remove sticky gums. After that, in the same tank, you will perform deacidification by adding an alkali solution to neutralize the free fatty acids. This combined process is very effective for small-scale refining. The impurities settle at the bottom as soapstock, which you can easily drain off.

Step 2: Decolorization in Tank 2

Next, you will move the cleaner oil into the second tank. This is the decolorization, or bleaching, tank. Here, you will mix the oil with activated clay. This special clay absorbs the dark color pigments from the oil. After mixing, you will pump the oil through a filter press that is attached to the machine. The filter traps the clay, and the oil that comes out is much lighter and clearer. The result is a much more appealing product, ready for bottling or selling.

Who is This Machine Specifically Designed For?

This small oil refinery machine is specifically designed for the small-scale entrepreneur who wants to add value to their product without a large investment. It is the perfect tool for a specific type of business owner.

We created this machine for people who are hands-on with their business. It is for those who are currently selling crude oil at a low price and see the opportunity to make more money by improving their product. It is the ideal entry point into the value-added food processing market. If you are operating on a small scale and want to grow your business step-by-step, this machine is your perfect partner.

The Small Oil Mill or Farm Owner

You have an oil press machine and produce oil from your own crops or from local farmers. A Edible oil refining machine allows you to take control of the entire production chain. You can refine your own oil and sell a finished product directly to consumers at a much higher profit margin.

The Startup Food Entrepreneur

You have a great idea for a local food brand, but you have a limited budget. This machine offers a low-cost way to start producing your own high-quality cooking oil. Its small size and simple operation mean you can start your business from a small workshop, keeping your initial costs low.

The Niche or Specialty Oil Producer

You work with special seeds like moringa, sesame, or walnut. You want to clean the oil to improve its appearance and shelf life, but you don’t want to strip away its unique natural character. The simplified refining process of a small machine is perfect for this. It purifies the oil gently, preserving its special qualities.

What are the Real Business Benefits for You?

The benefits of investing in a small oil refinery machine are direct and powerful for a small business. They are all about increasing profit and reducing risk.

This machine is more than just equipment; it is a business growth tool. Its main benefit is the low initial investment. It is the most affordable way to enter the oil refining business, which means you can see a return on your investment much faster. Its compact footprint is another huge advantage. You do not need to rent or build a large factory. You can likely fit it into your existing space, saving you a lot of money on overheads. Finally, its simple operation means you do not need to hire specialized staff. You or a single employee can run the machine, keeping your labor costs to a minimum. All of these factors combine to make it a smart, low-risk investment for your business.

| Feature | Small Refinery Machine | Large Industrial Refinery | What This Means for Your Business |

|---|---|---|---|

| Investment Cost | Low | Very High | You can start your refining business with much less capital. |

| Footprint | Small (fits in a workshop) | Huge (requires a large factory) | You save a lot of money on rent and building costs. |

| Operation | Simple, manual, batch | Complex, automated, continuous | You have lower labor and training costs. |

| Flexibility | High (easy to switch oil types) | Low (designed for one type) | You can easily adapt to different market demands. |

| Best For | Startups, small mills | Large corporations | This machine is built for entrepreneurs like you. |

Summary and Recommendation

So, what is a small oil refinery machine? It is the smartest first step for any small-scale oil producer who wants to make more money. It is a compact, affordable, and easy-to-use system that performs the essential refining steps to dramatically improve your oil’s quality.

This machine is the perfect choice for small mill owners, startup entrepreneurs, and specialty oil producers. It provides a fast return on investment by allowing you to produce a higher-value product with minimal overheads. If you are ready to grow your oil business beyond selling a raw commodity, the Refining equipment is the most practical and profitable tool to get you there.

About Fude Machinery

We are Fude Machinery, a professional B2B manufacturer of oil processing equipment based in Zhengzhou, China. We specialize in building reliable and affordable machinery for small and medium-sized enterprises all over the world. As a factory-direct company, we offer the small oil refinery machine and other equipment at competitive prices. We are proud to have helped entrepreneurs in over 30 countries start and grow their successful oil businesses.

Are you ready to turn your crude oil into bigger profits?

Contact our expert team at Fude Machinery today. We will provide a free consultation and help you determine if this small-scale solution is the perfect fit for your business goals.

Related recommendations

-

What are the technical parameters of a drum dryer

791Drum dryer, used to dry wet materials with anti pollution requirements. Suitable for drying chemical products, powders, straw, shavings, wood chips, and mixed coal materials.

View details -

What is the purpose of a tea seed sheller

607The tea seed peeling machine is mainly used for processing oil tea fruits, such as impurity removal, peeling, and sorting

View details -

Why Is Soybean Oil So Popular Globally?

418Soybean oil is a very common cooking oil around the world. Many people use it every day in kitchens and in food production. Its widespread use is no accident. We at Fude Machinery understand the full journey of soybean oil production. We make the...

View details -

What machine can press soybean oil

486Soybean oil press is one of the commonly used equipment for squeezing soybean oil

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business