What is palm oil extraction really about?

Need to get oil from palm fruit? It seems complicated. I can explain how palm oil extraction works.

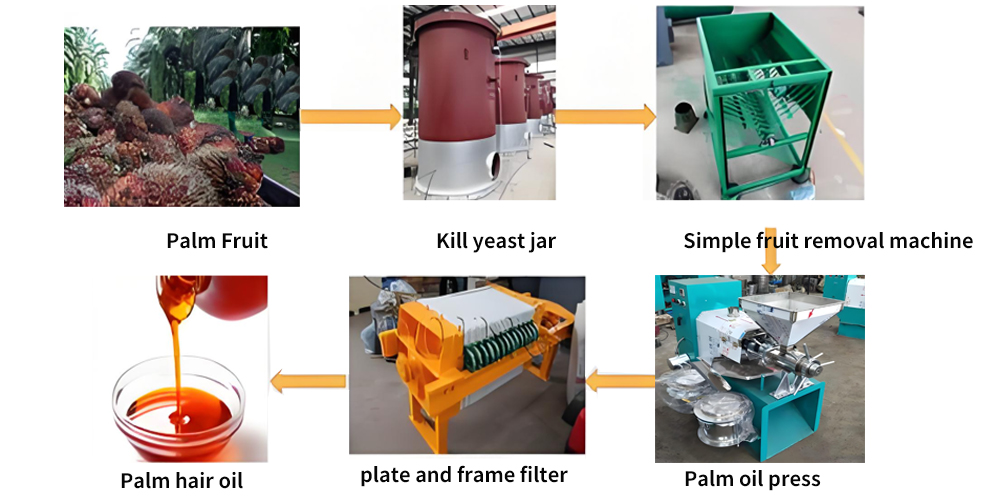

Palm oil extraction takes fresh fruit bunches (FFB) through stages like heating, shaking, pressing, and cleaning to make crude palm oil (CPO). It separates the valuable oil from the rest of the fruit material. This process needs specific machinery.

Getting oil from palm fruit is a step-by-step process. I want to walk you through the main parts.

Why is sterilization needed in palm oil processing?

Palm fruit starts to spoil quickly. This makes getting good oil difficult. So, you need to stop this fast.

Sterilization heats the fresh fruit bunches (FFB) using steam. This stops enzymes from breaking down the oil. It also helps loosen the fruit from the bunch.

Sterilization is the first big step. I use high-temperature steam for this. It has several important jobs. First, it stops the lipase enzyme. This enzyme breaks down oil and increases free fatty acids (FFA). High FFA makes the oil lower quality. Stopping it keeps the crude palm oil (CPO) better. Second, sterilization makes the fruit softer. This makes the next step, threshing, much easier. The fruit falls off the bunch more easily. Third, the heat helps to prepare the nuts inside the fruit. This makes it easier to separate them later. It also kills germs and insects on the fruit. This keeps the process clean. Sterilization makes the whole extraction process work better and gives a higher yield of good quality oil. It is a critical start.

How do you efficiently get oil from palm fruit?

You need to get the oil out of the fruit pulp and kernel. This is the core part of extraction. It needs strong equipment.

I use specialized pressing machines to squeeze the oil out of the softened palm fruit. This separates the crude oil from the fiber and nuts.

After sterilization and threshing, the fruit goes to the pressing stage. This is where the crude palm oil (CPO) is physically removed. The most common method I use is mechanical pressing. A screw press is the key machine here. It has a helical screw inside a barrel. The screw turns and pushes the digested fruit material forward. As it moves, the pressure increases. This high pressure squeezes the oil out through holes or slots in the barrel walls. The oil flows out and is collected. The solid residue, called press cake, comes out the other end. This press cake contains fiber and nuts. My screw presses are designed to be very efficient. They apply steady, high pressure. This maximizes the amount of oil extracted. The design of the screw and barrel is important. It affects the pressure distribution and oil drainage. Good design means more oil comes out and less oil is left in the press cake. I focus on strong materials too. Palm fruit is hard on machinery. My presses are built to last. They handle large volumes and work continuously. This is good for businesses that need high output.

What happens after crude palm oil is extracted?

The oil just squeezed out is not fully clean. It contains water, dirt, and other things. You cannot use it like this.

After pressing, the crude palm oil (CPO) needs cleaning and separation. This removes impurities like water, sludge, and fiber particles from the oil.

The liquid from the press is crude palm oil (CPO). But it is not pure. It has water, suspended solids like fiber and dirt, and sometimes traces of oil from the nuts that broke. This mixture goes to the clarification station. Here, I use various processes to clean the CPO. First, hot water is added. This helps separate the oil from the sludge. Then, the mixture often goes through vibrating screens to remove larger solids. After that, it flows into clarification tanks. In these tanks, hot CPO and water separate by gravity. The clean oil, being lighter, rises to the top. The heavier water and sludge settle at the bottom. I use centrifugal separators next. These machines spin the oil and water mixture very fast. The centrifugal force pushes the heavier water and solids outwards. The cleaner oil stays in the center. This step removes even more impurities and water. It gets the oil to a better state. Sometimes, vacuum drying is used too. This removes the last bit of water from the CPO. This results in cleaner, more stable crude palm oil. It is now ready for storage or further refining. This cleaning is important for quality.

Why is quality crucial in palm oil equipment?

Buying machinery is a big investment. Poor quality equipment can cause many problems. You need machines that work well and last.

High-quality oil extraction equipment ensures reliable operation, higher oil yield, and lower maintenance costs over time. It directly impacts your business profitability.

Equipment quality is not just a buzzword. It directly affects how much money you make. If a machine breaks down often, you lose production time. Lost time means lost money. Poorly designed machines might not extract all the oil. This lowers your yield. A lower yield means you process the same amount of fruit but get less sellable oil. My company, Zhengzhou Fude Machinery, builds durable equipment. I use strong materials for parts like the screw press worm. These parts handle high pressure and friction. Good material means they last longer. I also design for efficiency. My machines extract the maximum amount of oil possible from the fruit. This increases your yield per ton of fruit. Less maintenance is another benefit of quality. Well-built machines need fewer repairs. This saves you money on parts and labor. It also reduces unexpected downtime. I offer full service, including installation and training. This ensures the machines work correctly from day one. Investing in quality equipment upfront saves you a lot of trouble and money in the long run. It makes your operation smoother and more profitable.

How can my business benefit from modern palm oil machinery?

Old methods or outdated machines can limit your output. They might cost you more in the long run. You could be missing out on opportunities.

Modern palm oil extraction machinery offers increased automation, higher efficiency, better oil quality, and the ability to customize for specific needs.

Using modern machinery changes how your business operates. It makes everything better. For example, automation reduces the need for manual labor. This lowers your operating costs. It also makes the process more consistent. Automated systems can control temperature and pressure precisely. This results in stable, good quality oil. My machines are designed for high output. A modern screw press can process many tons of fruit per hour. This means you can handle more raw material faster. If you have a larger supply of fruit, you can process it all. This increases your total production volume. I also offer customization. Every customer is different. They might process a specific type of palm fruit. They might have limited factory space. They might have unique power supply conditions. I can design equipment or a whole complete production line to fit these needs. This tailored approach ensures the equipment works perfectly for your specific situation. It is not a one-size-fits-all solution. Modern machinery is also built with energy saving in mind. This lowers your power bills. All these benefits add up. They make your palm oil business more competitive and more profitable.

Advantages of Modern Machinery

| Advantage | Impact on Business | Example Feature |

|---|---|---|

| Increased Yield | Process more oil from same amount of fruit. | Efficient screw press design. |

| Lower Costs | Reduced labor and energy expenses. | Automation, energy-saving design. |

| Better Quality | Consistent oil characteristics, less FFA. | Precise process control. |

| Higher Output | Process larger volumes of raw material faster. | Continuous operation capability. |

| Customization | Equipment fits specific needs and conditions. | Tailored line design. |

Palm oil extraction is a detailed process. It needs good equipment at each step. Zhengzhou Fude Machinery provide machines to help you do this well.

Related recommendations

-

The function of tea seed refining machine

592The tea seed refining machine is a complete set of equipment used for refining and processing tea seed oil. It aims to remove impurities, free fatty acids, pigments, and odor substances from crude oil, enhancing the quality of the oil to meet edi...

View details -

How to choose a cold press oil press

312A cold press oil machine extracts oil using pure mechanical force while keeping the temperature very low. The main goal is to avoid heat. Heat can destroy the valuable vitamins, antioxidants, and natural flavors in the oil. This is why "cold p...

View details -

What are the factors that affect olive oil?

454Worried about bad olive oil? Poor quality oil wastes money. You need to know what makes oil good. Many things affect olive oil quality. These include the olive type, where it grows, when and how you pick it, how you process it, and how you stor...

View details -

How does refining work

756The basic working principle of refining equipment is to remove impurities such as protein, mucus, phospholipids, water, pigments, gossypol, etc. from the crude oil through physical or chemical principles, in order to obtain finished oil that ...

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business