What is the purpose of a refining machine

An oil refining machine has one main job. It cleans crude oil. It turns a raw, often dark, and strong-smelling liquid into a clean, stable, and valuable product. At Fude Machinery, we build these machines for a huge variety of uses. The scope is much wider than just the bottle of cooking oil in your kitchen.

We provide solutions for many different industries. These industries include large-scale food production, green energy like biodiesel, high-purity cosmetics, and other technical applications. This guide will show you the broad and important scope of use for a modern refining machine.

Last updated: June 2025 | Estimated reading time: 14 minutes

This article will explain for you:

- How is a refiner used in the food industry?

- How does it help make green biofuels?

- How is it used to make cosmetic products?

- What are its other industrial uses?

Application of Refining Machine in Edible Oil

The largest use for oil refining machines is in the food industry. This is the market most people know. After you press seeds like soybeans or sunflowers, you get crude oil. This crude oil contains things that make it unstable. It can go bad quickly and has a strong flavor. An oil refining machine removes these impurities. The process typically involves degumming, neutralization, bleaching, and deodorization.

The final product is called RBD oil (Refined, Bleached, Deodorized). It is light in color, has a neutral taste, and a long shelf life. This is the oil you find on supermarket shelves.

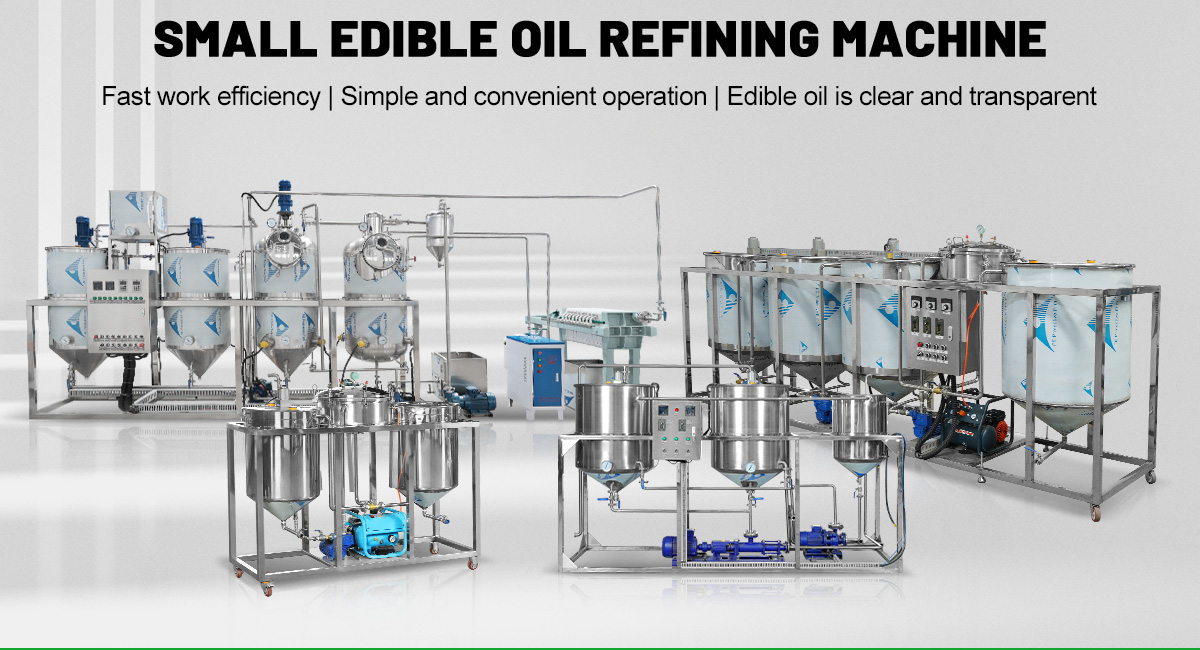

For Your Small Oil Business

If you are a small business owner, perhaps with a farm or a small oil press, a batch oil refining machine is a powerful tool for you. It allows you to take the crude oil you produce and greatly increase its value. Unrefined oil has a short shelf life and can only be sold locally at a low price. By refining it, you create a stable product that can be bottled and sold in local stores for a much higher profit.

Our small-scale batch systems are designed to be affordable and easy to operate. You do not need to be a chemical engineer to use them. They give you the power to control your product quality and build your own brand.

For Your Large Food Corporation

If you are a large food manufacturer, your needs are different. You need massive volumes of oil with absolute consistency. The oil used in your cookies today must be identical to the oil used next month. For you, we design and build large, fully automated continuous oil refining machines. These systems are the heart of a complete oil mill plant.

They run 24/7 with minimal operator input. Our focus for your business is on maximizing efficiency. This means reducing energy consumption, minimizing oil loss, and ensuring the final product meets strict international food safety standards. These machines are a critical part of the global food supply chain.

How Does it Help Make Green Biofuels?

Another very important use for a refining machine is in the production of biofuel, especially biodiesel. Biodiesel is a renewable fuel. It is made from vegetable oils or animal fats. However, you cannot simply put crude vegetable oil into a diesel engine. Crude oil contains impurities like free fatty acids (FFAs), water, and solid particles. These substances will clog fuel injectors and damage the engine over time. Before the oil can be converted into biodiesel, it must be cleaned. This is where the oil refining machine comes in. It acts as a pre-treatment system.

The refining process removes all the harmful impurities from the crude oil. The main goal here is to reduce the FFA content to a very low level, often below 1%. A low FFA level is critical for the next chemical process (transesterification) to work efficiently. Our machines provide a reliable way to produce this clean oil feedstock. This allows biofuel producers to use lower-cost raw materials, like used cooking oil or lower-grade vegetable oil, and still create a high-quality fuel. This use is growing fast as the world looks for more sustainable energy sources.

| Impurity in Crude Oil | Why It Must Be Removed for Biofuel | How Our Machine Helps You |

|---|---|---|

| Free Fatty Acids (FFAs) | High FFAs react to form soap, which ruins the biodiesel process. | Our neutralization step removes the FFAs effectively. |

| Water and Moisture | Water interferes with the chemical reaction, leading to low yield. | Our heating and vacuum processes remove all water. |

| Gums and Solids | These can clog filters and reactors in the biodiesel plant. | Our degumming and filtration steps produce a perfectly clean oil. |

How is it Used to Make Cosmetic Products?

The cosmetic and personal care industry is another key user of oil refining machines. This is a high-value market where purity is everything. Many lotions, creams, soaps, and hair care products use natural oils as a base ingredient. These can include specialty oils like shea butter, cocoa butter, argan oil, or jojoba oil.

When these oils are in their crude form, they have strong natural colors and odors. While this might be fine for some “natural” products, it is a problem for most commercial cosmetics. The oil must not affect the final product’s planned color or fragrance.

For this industry, we provide specialized oil refining machines, often on a smaller scale. The goal is to produce an oil that is completely neutral. The refining process carefully removes all the color pigments and odorous compounds. This creates a beautifully clear, white, or light-yellow oil with no smell. This pure base oil is then ready to be mixed with other active ingredients, vitamins, and fragrances to create the final cosmetic product. Our ability to customize these smaller, high-purity systems makes us a valuable partner for businesses in this quality-focused sector.

What is the purpose of refining machines in industry

The scope of use for a refining machine extends to many other industrial applications beyond food and fuel. Many technical products require the specific properties of refined oils. The refining process can be adjusted to achieve different results depending on the final use. For example, some oils are used as a base for paints and varnishes. Refining ensures the oil will dry properly and form a durable film. Other oils are refined to be used as industrial lubricants or hydraulic fluids.

A great example is castor oil. In its crude form, it has many uses, but for high-grade industrial applications, it needs to be refined. Removing impurities ensures it has the right viscosity and thermal stability to perform as a high-performance lubricant in machinery. For these technical markets, we engineer our oil refining machines to meet very specific technical specifications. It shows the true versatility of the equipment. It is not just about making oil edible; it is about engineering a liquid raw material to fit hundreds of different industrial needs.

Frequently Asked Questions

Question 1: What is the main purpose of an oil refining machine?

The main purpose of an oil refining machine is to purify crude vegetable or animal oil. It removes impurities like free fatty acids (FFAs), gums, pigments (color), and odors. This process creates a stable, high-quality oil that is suitable for cooking, food manufacturing, or other industrial applications.

Question 2: Can one refining machine be used for different types of oil?

Yes, especially our batch refining systems. They are very flexible. You can use the same machine to refine sunflower oil, soybean oil, peanut oil, and many others. We just help you adjust the process parameters like temperature and chemical dosage for each different type of oil to get the best results.

Question 3: Is refining necessary for all cooking oils?

Not all, but most of them. Oils sold for high-temperature cooking like frying need refining to improve their stability and smoke point. Some ‘cold-pressed’ or ‘virgin’ oils are not refined to keep their natural flavor, but they have a shorter shelf life and are not suitable for all cooking methods. Refining makes oil more versatile and last longer.

Summary and Recommendation

The scope of use for an oil refining machine is incredibly broad and diverse. While its most common application is producing edible oil for the food industry, its role is just as critical in other major sectors. It is a key piece of equipment for creating clean feedstock for the biofuel industry. It is essential for producing the pure, neutral oils required by the cosmetics industry. It is also a vital tool for creating specialized oils for various industrial products.

At Fude Machinery, we understand this wide scope. We have the experience to design and build a refining solution for any of these applications, at any scale.

Do you have a project in one of these industries? Let’s discuss how we can help.

Contact our technical team today. We are ready to provide expert advice and a detailed proposal for your specific application.

Related recommendations

-

What is an oil press

892Definition: An oil press is a mechanical device that extracts oil from oily plant seeds (such as peanuts, rapeseed, sesame, sunflower, corn germ, coconut, palm kernel, soybean, etc.) through physical pressure or chemical methods. It replaces the ...

View details -

What Affects Palm Oil Yield and Quality Most?

467Bad palm oil yield costs money. Poor quality oil is hard to sell. We will tell you key factors. The main things affecting palm oil yield and quality are the fresh fruit bunches, how you process them, and the machines you use. Getting these righ...

View details -

What is the difference between hot pressing and cold pressing in an oil press

683Oil presses are divided into hot presses and cold presses in terms of processing technology, oil characteristics, and usage scope.

View details -

What are the core steps in making peanut oil?

580Want to make peanut oil? It needs more than just squeezing peanuts. Understanding the steps is key. Making peanut oil involves key steps. These include preparing the peanuts, pressing the oil out, and then cleaning the oil. We do this to get hi...

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business