What Is the Purpose of an Oil Refinery Machine?

The main purpose of an oil refinery machine is to purify crude oil. When oil is first extracted from seeds using an oil press, it is called crude oil. This crude oil is not ready for sale as a high-quality edible product. It contains many natural impurities. Our oil refinery machines are designed to remove these impurities. This process makes the oil stable, visually appealing, and safe for consumption. It transforms a raw product into a valuable finished good. At Fude Machinery, we build these systems to help you achieve a higher market price for your oil.

Last updated: May 2025 | Estimated reading time: 10 minutes

Table of Contents

- Why Must You Refine Crude Vegetable Oil?

- What Are the Main Steps of the Oil Refining Process?

- How Does an Oil Refinery Machine Increase Your Profits?

- What Type of Oil Refinery Machine Do You Need?

Why Must You Refine Crude Vegetable Oil?

You must refine crude oil because it contains impurities that make it unsuitable for most uses. After pressing, the oil is not pure. It contains things like phospholipids (gums), free fatty acids (FFAs), pigments, and volatile compounds.

These impurities cause many problems for your business. For example, they can give the oil an unpleasant taste and odor. They can make the oil look cloudy or dark. They also cause the oil to spoil very quickly, giving it a very short shelf life.

As a manufacturer, we understand your goal is to produce a product customers want to buy. Customers expect cooking oil to be clear, light-colored, and have a neutral taste. The impurities in crude oil prevent it from meeting these expectations.

They can also cause problems during cooking, like smoking at low temperatures. An oil refinery machine is the essential tool that solves these problems. It is the bridge between low-value crude oil and high-value, marketable edible oil.

By removing the impurities, you create a product that can be sold in supermarkets and used by food processing companies.

What Are the Main Steps of the Oil Refining Process?

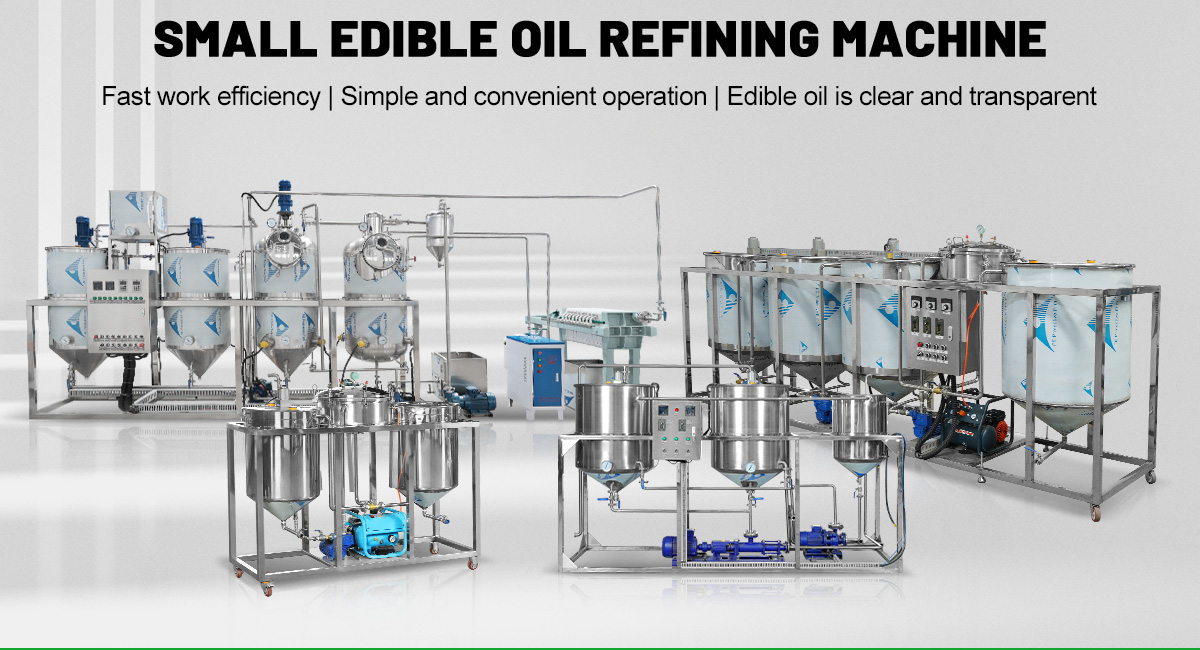

The oil refining process has four main steps: degumming, deacidification, decolorization, and deodorization. A complete oil refinery machine from Fude Machinery is actually a system of connected tanks and equipment, where each unit performs one of these crucial steps. Think of it as a production line for purification. The crude oil goes in one end, passes through these four stages, and comes out the other end as clear, pure, finished oil. Understanding this process shows you the true purpose of the equipment.

We design our refinery equipment to handle this entire process efficiently. Whether you need a small batch system for a few tons per day or a large continuous plant, the fundamental science is the same. Each step targets and removes a specific type of impurity. This systematic removal is what guarantees a final product of consistently high quality. Let’s look at each of these four steps in more detail.

Step 1: Degumming (Removing Gums)

The first purpose is to remove phospholipids, also known as gums. In crude oil, these gums absorb water and create a cloudy appearance. If you don’t remove them, they will settle at the bottom of the bottle as sediment. During heating, they burn and turn the oil dark. The degumming process involves mixing the oil with a small amount of hot water or acid. This makes the gums clump together so they can be easily separated by a centrifuge.

Step 2: Deacidification (Neutralizing Acid)

The next purpose is to remove Free Fatty Acids (FFAs). FFAs give the oil a sour, rancid taste and cause it to spoil much faster. The most common method to remove them is called alkali refining. We add a precise amount of an alkali solution, like caustic soda. This solution reacts with the FFAs to form soapstock. The soapstock is heavier than the oil and is separated out. This step is critical for improving the oil’s flavor and stability.

Step 3: Decolorization (Removing Color)

After deacidification, the oil may still have unwanted color from natural pigments like chlorophyll or carotenoids. The purpose of decolorization, or bleaching, is to remove these pigments. This makes the oil lighter and clearer. To do this, the oil is mixed with a special adsorbent material, usually activated clay or bleaching earth. This clay acts like a magnet for color pigments. After mixing, the oil is filtered to remove the clay, which takes the colors with it.

Step 4: Deodorization (Removing Odors)

The final step is to remove any remaining unpleasant tastes and odors. These are caused by volatile compounds. The purpose of deodorization is to make the oil completely bland and neutral. This is done by treating the oil with high-pressure steam under a vacuum at a high temperature (over 200°C). The steam strips away the volatile odor compounds, which are then carried away by the vacuum system. This final polish ensures the oil has a clean taste and smell.

| Refining Step | Impurity Removed | Why It’s Important for Your Oil |

|---|---|---|

| Degumming | Phospholipids (Gums) | Prevents cloudiness and sediment in the bottle. Improves stability. |

| Deacidification | Free Fatty Acids (FFAs) | Removes sour taste. Greatly increases the oil’s shelf life. |

| Decolorization | Color Pigments | Creates a clear, light-colored oil that customers find more appealing. |

| Deodorization | Odor Compounds | Results in a neutral, clean-tasting oil suitable for all types of cooking. |

How Does an Oil Refinery Machine Increase Your Profits?

An oil refinery machine increases your profits by transforming a basic commodity into a premium product. The price difference between crude oil and refined oil is significant. By investing in an oil refinery machine, you capture that added value for your own business. You are no longer just selling raw materials to a larger processor. You are creating a finished good that can be sold directly to consumers or to food manufacturing companies at a much higher price point. This single change can fundamentally improve the profitability of your entire operation.

This equipment also opens up new markets for you. Many national and international food safety standards require oils to be fully refined. Without a refinery, you cannot access these lucrative markets. Your refined oil will have a longer shelf life. This means you can store it for longer and transport it over greater distances without spoilage. This reduces product loss and gives you more flexibility in your sales strategy. We have seen our clients in many developing countries use our refinery systems to start their own brands and compete with large importers, creating sustainable local businesses.

What Type of Oil Refinery Machine Do You Need?

The type of oil refinery machine you need depends on your production scale and business goals. At Fude Machinery, We manufacture different types of systems because our customers have different needs. A small, new oil mill has very different requirements from a large, established industrial group. Our job is to provide you with the most cost-effective and efficient solution for your specific situation.

We can help you analyze your raw material input, your target output per day, and your available budget. This will help us recommend the right system. Choosing the correct type of refinery is one of the most important decisions you will make. It directly impacts your initial investment and your long-term operating costs. We offer full support in making this choice, ensuring you get a system that supports your growth.

Batch (Intermittent) Refinery Equipment

This is the perfect choice for small to medium-sized businesses. This includes small oil mills, specialty oil producers, or businesses processing 1 to 20 tons of crude oil per day. A batch system processes the oil in separate lots. It is more affordable to install and offers great flexibility. You can easily switch between refining different types of oil. The operation is simple, making it ideal for businesses just starting with oil refining.

Continuous Refinery Equipment

This type of system is designed for large-scale industrial production, typically for operations processing over 30 tons of oil per day. As the name suggests, oil flows through the system in a continuous stream, 24/7. While the initial investment is higher, the operating cost per ton of oil is much lower. It is highly automated and extremely efficient, making it the best choice for large edible oil groups looking to maximize output and minimize labor costs. Our engineering team can design a complete oil mill plant that integrates a continuous refinery for maximum efficiency.

Real-world Example:

A customer in Ethiopia was operating a successful peanut oil pressing business but selling all their crude oil to a large refiner at a low price. They purchased our 5-ton-per-day batch oil refinery machine. This allowed them to produce their own branded, refined peanut oil. They now supply local supermarkets and hotels, and their profit margin on each liter of oil has increased by over 150%.

Frequently Asked Questions

Question 1: I have an oil press, do I really need an oil refinery machine?

If you want to produce high-quality, food-grade edible oil for retail, then yes. An oil press gives you crude oil. An oil refinery machine purifies that crude oil to make it stable, flavorless, and visually appealing, which is what consumers and food companies demand.

Question 2: What is the difference between physical and chemical refining?

Chemical refining uses an alkali like caustic soda to neutralize free fatty acids. Physical refining uses steam distillation under high temperature and vacuum to remove them. Physical refining is often seen as more environmentally friendly and can result in higher yields, which is why our newer equipment focuses on this method.

Question 3: How much space does a small oil refinery machine need?

Our batch refinery systems are designed to be compact. A small unit for 1-2 tons per day can fit in a small workshop. We can also customize the layout of the tanks to fit your specific building dimensions. Contact us, and we can provide a layout plan for you.

Summary and Recommendation

The purpose of an oil refinery machine is clear: it purifies crude oil through a four-step process—degumming, deacidification, decolorization, and deodorization. This purification is essential to create a stable, safe, and high-value edible oil that meets market standards. Investing in refining equipment directly increases your profitability by allowing you to sell a premium product and access wider markets.

Your choice between a batch or continuous system depends on your production volume. For most small to medium enterprises, a flexible and cost-effective batch refinery is the ideal starting point. It empowers you to take control of your product quality and your profits.

About Fude Machinery

We are Fude Machinery, a leading manufacturer of oil processing equipment in Zhengzhou, China. We specialize in providing B2B solutions, from individual machines to complete, customized production lines. Our products are trusted by businesses in over 120 countries. As a factory-direct seller, we pride ourselves on delivering high-quality, reliable, and well-supported equipment that helps our clients grow.

Ready to turn your crude oil into a premium product?

Contact our expert team today. We will help you understand your needs and recommend the perfect oil refinery machine for your business.

Related recommendations

-

What is palm oil?

576As a widely distributed plant in tropical and subtropical regions, the palm's use spans a wide range of ecological, economic, cultural and other fields, demonstrating extremely high comprehensive utilization value. Palm kernel oil press machi...

View details -

What is the difference between a box dryer and a drum dryer

518There are significant differences between box drying rooms and drum drying machines in terms of structure, working principle, scope of application, and advantages and disadvantages.

View details -

The effectiveness of using a vertical dryer

509Vertical dryers have demonstrated excellent performance in multiple fields due to their high efficiency, energy saving, uniform drying, easy operation, safety and reliability, wide applicability, and convenient maintenance

View details -

How to Use a Screw Oil Press to Boost Your Edible Oil Production?

128Seeking versatility and quality in edible oil production? A single machine offers both delicate cold pressing and efficient hot pressing, transforming your output. A stainless steel screw oil press with cold/hot dual-mode capability prov...

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business