Why should we choose physical pressing method to obtain oil

Physical pressing oil

Perhaps we all know that there are two methods for producing crude oil: one is the physical pressing method using an oil press, and the other is the chemical solvent extraction method supplemented with various chemical additives throughout the production process. Nowadays, physical pressing methods have become increasingly popular. Why?

First, physical pressing is much environment protection.

- Although the chemical solvent extraction method extracts oil from oilseeds by adding food grade chemical solvents, it inevitably results in residual chemicals in the finished oil. The physical pressing method extracts oil from various oilseeds through physical pressure, and the entire process is environmentally friendly and does not cause any damage to the oil itself or the environment.

Second, the physical pressing method has higher oil yield and lower cost than before.

- With the rapid development of technology, the technology of physical pressing has been significantly improved. Especially recently, many hydraulic presses have adopted multi-stage pressing technology, which not only improves oil yield but also achieves higher output at lower costs.

Thirdly, improving people’s quality of life requires high-quality edible oil.

- With the continuous progress of society, people’s quality of life will continue to improve, and their requirements for food will also increase. They will pay more attention to the items they consume. Therefore, physical pressing oil will undoubtedly have a broad and lasting market. For enterprises engaged in edible oil production, choosing physical pressing method will be a wise strategy.

The advantages of material oil extraction

The advantages of material oil extraction are mainly reflected in the following aspects, which not only improve production efficiency, but also ensure the quality and economic benefits of oil products:

- High efficiency: Modern oil presses significantly improve work efficiency by strengthening the feeding system and increasing the propulsion speed. For example, the working efficiency of some new oil presses can be improved by more than 30%. In addition, multi-stage pressing technology can ensure a clean press, thereby improving overall production efficiency.

- High oil yield: The oil press adopts technologies such as directional pressure and multi-stage propulsion, which significantly improves the oil yield. Compared with old-fashioned equipment, the normal oil output rate can be 4-6 percentage points higher. This means that with the same raw material input, more edible oil can be obtained, thereby improving economic efficiency.

- Pure oil quality: The oil press can automatically filter the residue during the oil pressing process and ensure the purity of the oil quality through technologies such as vacuum filtration. This complies with health and quarantine standards, making homemade edible oil healthier and safer.

- Cost saving: Compared to edible oils on the market, homemade edible oils have lower costs. This is not only because of high oil yield and high utilization of raw materials, but also because it can avoid unnecessary chemical components and additional costs that merchants may add.

- Widely used: The oil press can extract various oil crops, such as peanuts, sesame seeds, rapeseed, cottonseeds, soybeans, etc. This makes the oil press have a wider range of applications and can meet the needs of different users.

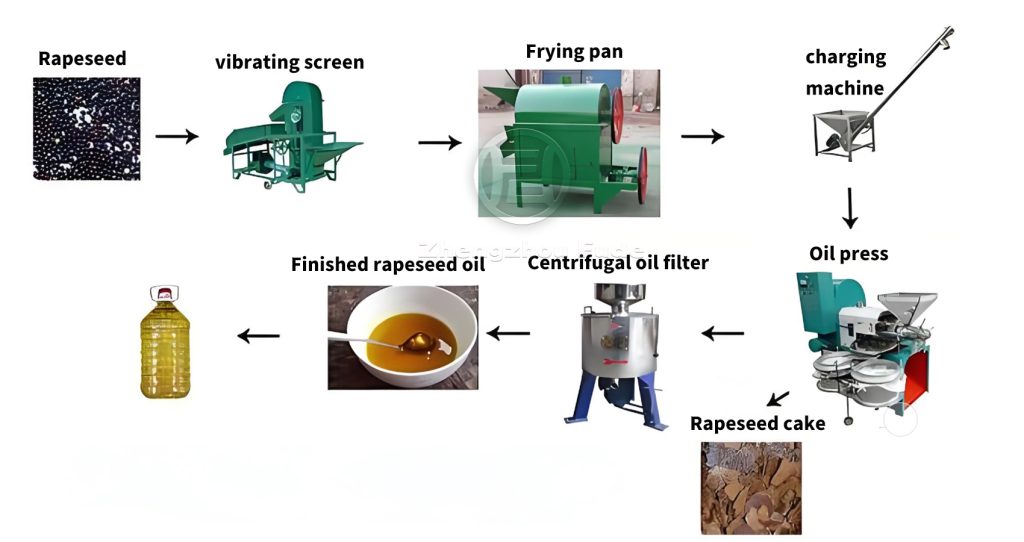

- Fully automatic operation: The fully automatic oil pressing equipment adopts full automation operation, which improves production efficiency and convenience. Its working principle is to feed the pre pressed material into the press machine through a conveyor, and push the material through components such as the hopper, upper pressing cage, and pressing screw. The oil extraction degree is controlled by adjusting the oil outlet clearance, and the hydraulic cylinder piston extracts the oil from the press chamber. Oil can be recycled after collection, stirring, and impurity precipitation. The advantage of fully automatic oil extraction equipment lies in its fully automated operation, which reduces manual labor intensity and is suitable for various raw materials such as sesame, rapeseed, walnuts, peanuts, soybeans, rapeseed, tea seeds, etc. By controlling temperature, pressure, and time, high-quality oils and fats can be produced.

- The advantages of material oil extraction are not only reflected in production efficiency and economic benefits, but also in oil quality, environmental protection and health, and technological innovation, making it an important means of modern oil processing.

Zhengzhou Fude Machinery manufactures automatic hydraulic presses and spiral hydraulic presses for industrial use, and provides multiple types for your reference. These machines have a small footprint and are easy to operate. Once you make a purchase, we will not only provide you with comprehensive technical guidance, but also offer excellent service. Sincerely welcome to visit at any time.

Related recommendations

-

Which regions are suitable for using tea seed peelers for tea seeds

529Hunan, Jiangxi, Guangxi, Hubei, Guangdong, Henan, Anhui, Guizhou and other major oil tea producing provinces in China. The tea seed production in these regions is large, and the demand for tea seed peelers is relatively high

View details -

Can Ignoring Crude Oil Quality Ruin Oil Refining?

372Chemical refining, mainly using alkali to neutralize Free Fatty Acids (FFA), is the traditional method. It's robust and adaptable. It works well even if your crude oil quality isn't perfect or has high acidity. The process involves adding an alk...

View details -

Diversified display of multifunctional drum dryer

446The diversified display of multifunctional drum dryers is mainly reflected in their wide application fields, diverse functional designs, and continuous technological innovation

View details -

What is the drying principle of a drum dryer

608The drying principle of a drum dryer is to evaporate the moisture in the material through three processes: heating, heat transfer, and mass transfer, thereby achieving the purpose of drying

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business