How to choose an oil press -5 major advantages

Starting or growing an edible oil business is a great goal. But to be successful, you need control over your product and your profit. The single best way to get this control is by owning your own equipment.

Choose oil press equipment, master the entire process of oil pressing, and enhance business scope and capabilities. We are Zhengzhou Fude Machinery, a comprehensive manufacturer that integrates manufacturing and sales. Customers from different countries have reported that the market demand for oil presses is increasing. This article will analyze the advantages of oil presses for you.

Table of Contents

- What types of oil are suitable for an oil press

- Determine the production capacity of the oil press

- Deciding on Your Oil Quality and Business Model

- Focusing on the Machine’s Durability and Maintenance

- Comprehensive solution for oil extraction equipment

What types of oil are suitable for an oil press

The first step to choose an oil press is to know your seeds. This is the most important factor. Different oilseeds have very different characteristics. Some are hard, like palm kernels. Some are soft, like walnuts. Some have high oil content, like sesame, and some have lower oil content, like soybeans. An oil press that works perfectly for peanuts might be very inefficient for flaxseeds. You must match the machine to your raw material. This will maximize your oil yield and prevent damage to the press.

Differences in Oil Yield of Oilseeds

- Soybeans: The oil yield is about 12% -18%, and the pressed soybean cake can be used as feed or protein raw material.

- Rapeseed: With an oil yield of 30% -45%, it is the main source of rapeseed oil.

- Peanuts: Oil yield of 40% -50%, rich aroma of peanut oil, high market value.

- Cottonseed: Oil yield of 10% -20%, requiring detoxification treatment before pressing. Cottonseed oil can be used for industrial or edible purposes.

- Sunflower seeds (oil sunflower): Oil yield 25% -40%, sunflower seed oil is rich in unsaturated fatty acids.

- Sesame oil: with an oil yield of 45% -55%, sesame oil (sesame oil) has a unique flavor and is suitable for cold pressing.

- Flaxseed: Oil yield of 30% -40%, flaxseed oil is rich in alpha linolenic acid and suitable for healthy consumption.

- Su seed (purple Su seed): Oil yield of 35% -45%, Su seed oil has medicinal value.

- Walnut kernels: Oil yield of 60% -70%, walnut oil is nutritious and suitable for infants and young children to consume.

- Almonds: Oil yield of 40% -50%, almond oil can be used in food or cosmetics.

- Coconut meat: Oil yield of 60% -70%, coconut oil is heat-resistant and suitable for cooking or industrial use.

- Olive fruit: Oil yield of 15% -25%, olive oil is the core oil of the Mediterranean diet.

- Palm fruit: Oil yield of 20% -30%, palm oil is a high-yield vegetable oil.

We design different types of presses because there is no single machine that is perfect for everything. The two main types are the screw oil press and the hydraulic oil press. The screw press is a versatile and continuous machine, making it the most popular choice for a wide variety of seeds like sunflower, rapeseed, and soybeans. It is a true workhorse.

The hydraulic press is a gentler, batch-process machine. It is the specialist for soft, high-value nuts and seeds where preserving a very specific flavor is critical, like cold-pressed sesame oil or walnut oil. Choosing the right type is your foundation for a successful business.

| Seed Type | Best Press Type | Why This Choice is Better for You |

|---|---|---|

| Hard Seeds (Palm Kernel, Cottonseed) | Heavy-Duty Screw Press | You need the extreme, continuous pressure a screw press provides to break down tough fibers and get good oil yield. |

| Common Seeds (Sunflower, Peanut, Rapeseed) | Standard Screw Press | This is the most efficient and cost-effective method for continuous, medium-to-large scale production of these oils. |

| Soft & High-Value Nuts (Walnut, Macadamia) | Hydraulic Oil Press | This press uses gentle, static pressure that extracts the highest quality oil without generating much heat, preserving delicate flavors. |

| Special Flavor Seeds (Sesame, Perilla) | Hydraulic or Specialized Screw Press | For premium sesame oil, a hydraulic press is often used to get the pure, raw flavor that customers pay a high price for. |

Determine the production capacity of the oil press

The next step is to choose an oil press with the right processing capacity. Capacity means how much raw material the machine can process in a set time, usually measured in kilograms per hour or tons per 24 hours (TPD). This is a critical business decision. If you buy a machine that is too small, you create a bottleneck. You will not be able to meet your customer demand, and you will miss out on sales.

You need to think about your business plan. How much oil do you plan to produce and sell each day? Start with that number and work backward. For example, if you want to produce 500 liters of sunflower oil per day, and sunflower seeds have about a 40% oil yield, you will need to process around 1,250 kg (1.25 tons) of seeds. So, you should look for a machine with a capacity of at least 1.5 to 2 tons per day to give yourself some room to grow.

As a manufacturer, we offer a wide range of models, from small commercial presses for startups (1 TPD) to large industrial machines for established oil mills (50 TPD or more).

| Model | Snail squeezing speed (r/min) | Capacity (kg/h) | Whole machine weight (kg) |

| 80 | 47 | 65-130 | 780 |

| 100 | 38 | 140-280 | 1100 |

| 125 | 36 | 300-400 | 1280 |

| 130 | 36 | 250-400 | 1380 |

| 150 | 35 | 500-600 | 1420 |

Sizing Your Operation

- Small Business / Startup : You are likely selling in a local market or just starting out. A smaller, flexible commercial oil press is your best bet. It has a lower initial cost and is easier to manage.

- Medium-Sized Oil Mill : You have an established customer base and need higher, more consistent output. You should look for a robust, industrial-grade screw press that can run for long hours. You may even need multiple presses to form a complete oil mill plant.

- Large Industrial Processor : At this scale, efficiency is everything. You will need a high-capacity pre-press machine combined with a solvent extraction plant to get the highest possible oil yield. This is a much larger investment but is necessary for competing at the industrial level.

Deciding on Your Oil Quality and Business Model

When you choose an oil press, you are also choosing your final product’s quality. This is about your business strategy. Do you want to produce a premium, healthy oil or a standard cooking oil? This decision will lead you to either cold pressing or hot pressing. The type of machine and the equipment you need around it will be different for each method.

A cold press oil machine extracts oil from raw seeds without adding any external heat. This gentle process protects the oil’s natural nutrients, color, and flavor. The result is a high-quality, premium product that can be sold for a much higher price. A hot press, on the other hand, requires the seeds to be roasted in a cooker or before pressing. The heat makes the oil flow out more easily, which gives you a higher oil yield.

The working principle of hot oil extraction and cold oil extraction

- Hot press oil press: Hot press uses high-temperature pretreatment (such as roasting, steaming) to denature oil proteins, destroy cell structure, reduce oil viscosity, and then press through mechanical pressure. High temperature promotes the fluidity of oil and improves oil yield.

- High temperature pretreatment: Oilseeds are subjected to high-temperature roasting or steaming at temperatures above 120 ℃ to cause thermal denaturation of proteins, disruption of colloidal structure, and increased plasticity.

- Mechanical pressing: The pre treated oil enters the pressing chamber, and under high pressure, the oil quickly precipitates and flows out through gaps.

- Refining process: Hot pressed crude oil needs to undergo refining treatments such as deacidification, decolorization, and deodorization to remove impurities and harmful substances.

- Cold press oil press: Cold press directly presses oil through physical and mechanical pressure in a low-temperature (usually below 60 ℃) environment, without involving high-temperature heating or chemical treatment throughout the process. After being carefully selected, cleaned, and crushed, the oil enters the press chamber. Under the high pressure generated by the rotation of the press screw, the oil is squeezed out of the cells and flows out through the gaps in the press chamber.

- Retain nutritional components: active substances such as vitamin E, sterols, and unsaturated fatty acids are not destroyed by high temperatures.

- Natural flavor: No high-temperature cooked aroma or chemical deodorization, retaining the natural aroma and color of the raw materials.

- Environmental protection and health: No need for refining, can meet edible standards through filtration alone, reducing the risk of chemical residues.

Practical Advice for Your Business

- Go Cold for Health Markets: If your target customers are health-conscious, organic buyers, or gourmet chefs, you must choose cold pressing. The higher price you can charge will more than make up for the slightly lower yield.

- Go Hot for Volume Markets: If you are competing in the general cooking oil market where price is the main factor, hot pressing is the better choice. The higher yield is essential for your profit margins at a larger scale.

- Remember the Extra Gear: If you decide on hot pressing, remember that you also need to purchase a good quality seed roaster. This needs to be factored into your startup budget.

Focusing on the Machine’s Durability and Maintenance

A smart business owner knows that the true cost of a machine is not its purchase price. The true cost includes maintenance, spare parts, and downtime. When you choose an oil press, you must look closely at its construction. A cheap machine made from low-quality materials will be a constant headache. It will break down often, wear out quickly, and produce an inconsistent product. A well-built machine from a reputable factory is a long-term investment that pays for itself.

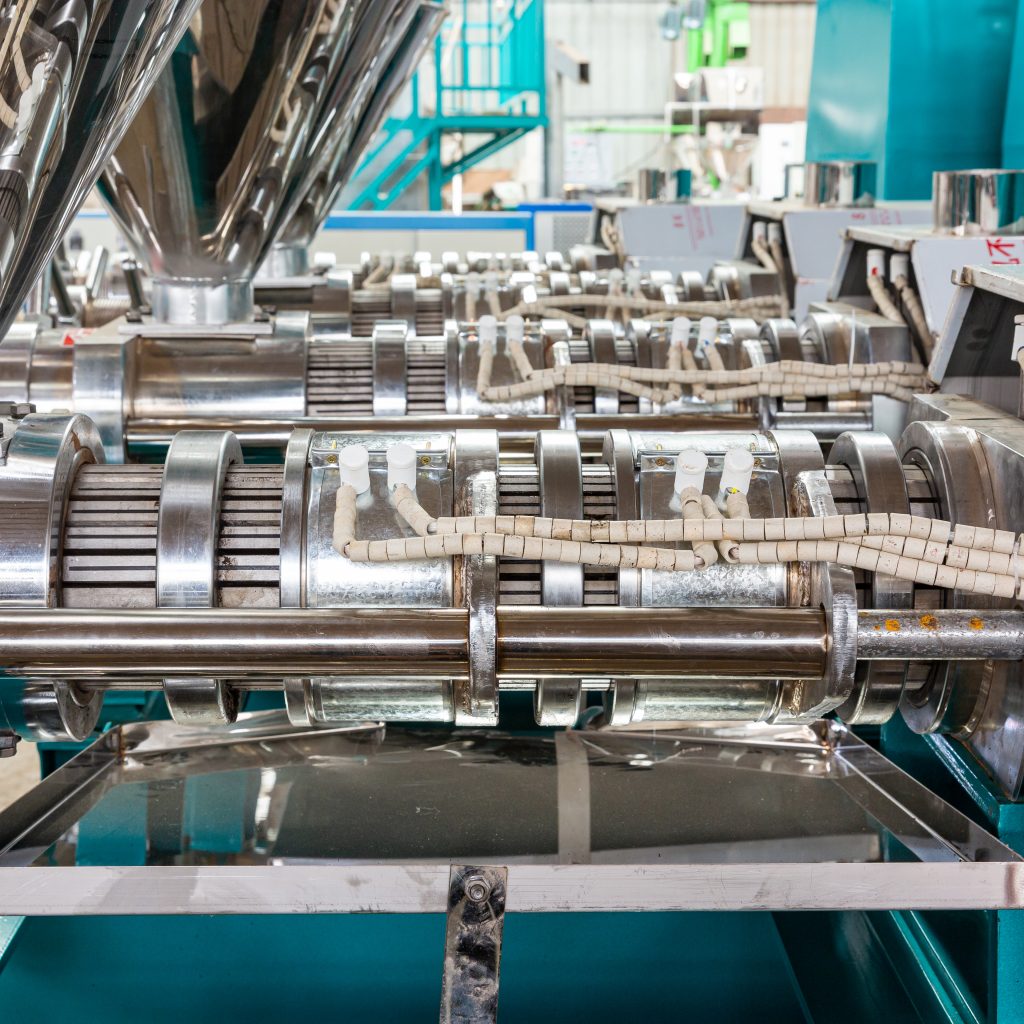

We are a direct manufacturer, so we control the quality of every part. The most important components in a screw press are the pressing screw and the barrel cage, also known as press rings. These parts are under extreme pressure and friction, so they are the main “wear parts.”

They must be made from high-grade alloy steel that has been properly heat-treated (a process called carburizing and quenching) to make it extremely hard and wear-resistant. A machine with high-quality wear parts will run for many more hours before needing replacements, saving you a lot of money and stopping production less often. Always ask the supplier about the materials and heat treatment of their wear parts.

Comprehensive solution for oil extraction equipment

Finally, remember that the oil press does not work alone. It is the center of a system. To run a successful business, you will need other machines. You will need a cleaner to prepare the seeds. You will need an oil filter to purify the crude oil. You might also need a sheller, a cooker, or a bottling machine. When you choose an oil press supplier, it is a huge advantage to choose one who can provide the entire solution.

As a company that designs complete oil production lines, we ensure that all our machines work together perfectly. This saves you a lot of time and trouble trying to connect equipment from different suppliers. Even more important is after-sales support. What happens if you have a problem? A good supplier offers installation guidance, operator training, and can quickly send you the correct spare parts when you need them. Being a factory-direct seller allows us to have a very close relationship with our customers. We provide technical support for the entire life of the machine, not just until it is sold. This kind of reliable partnership is one of the biggest advantages you can have in this business.

Frequently Asked Questions

Question 1: What is the main difference between a screw oil press and a hydraulic oil press?

A screw oil press uses a rotating screw to create continuous high pressure, great for most seeds and high capacity. A hydraulic oil press uses static pressure from a piston in batches, which is gentler and ideal for high-value, soft nuts like walnuts or for sesame oil to preserve its flavor.

Question 2: Do I need other machines besides the oil press?

The oil press is the heart of your operation, but you will need other machines. For good results, you at least need a machine to clean your seeds and an oil filter to purify the crude oil. For a complete production line, you may also need a sheller, a roaster, and bottling equipment.

Question 3: How much does a commercial oil press cost?

The cost varies widely based on capacity, power, and materials. A small commercial model for a startup might cost a few thousand dollars. A large industrial press can cost tens of thousands.

Summary and Recommendation

To choose an oil press that will make your business profitable, First, analyze your raw materials and your business goals. Then, select a machine that matches your required capacity and desired oil quality. Always prioritize durability and the quality of construction over a low price. Finally, choose a supplier who can be a true partner, offering a complete solution and reliable long-term support.

By carefully considering these five advantages—the right machine type, the right size, the right process, robust construction, and great support—you are not just buying a piece of equipment. You are laying the foundation for a successful and profitable oil business.

About Fude Machinery

We are Fude Machinery, a specialist B2B manufacturer of oil processing equipment based in Zhengzhou, China. As a factory-direct seller, we eliminate intermediate costs to provide our global clients with competitive pricing on reliable, high-performance machinery. We build complete, customized oil mill plants and all the essential components, including a full range of refinery equipment.

Are you ready to find the perfect heart for your oil business?

Contact our expert team at Fude Machinery today. We will provide a professional consultation and a detailed quotation to help you choose the right oil press machine for your needs.

Related recommendations

-

What is the difference between a box dryer and a drum dryer

519There are significant differences between box drying rooms and drum drying machines in terms of structure, working principle, scope of application, and advantages and disadvantages.

View details -

How to extract oil from sunflower seeds?

624Sunflower oil is an ingredient naturally derived from sunflower seed. It is also an ingredient used throughout the world to improve the quality of food. Cooking with butter is usually considered bad, but if you use the oil effectively and gradua...

View details -

What is the difference between hydraulic oil press and screw oil press

452Hydraulic oil press and spiral oil press are two common oil crop oil pressing equipment, which have significant differences in pressing principles, applicable oil materials, oil yield and efficiency, equipment advantages and disadvantages, etc.

View details -

The main working principle of screw oil press

864The main method is to use a spiral shaped screw rod to compress and rupture the oil under the pressure inside the squeezing chamber, thereby extracting the oil pressure from the oil.

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business