How to Address Common Issues in Waste Oil Refining?

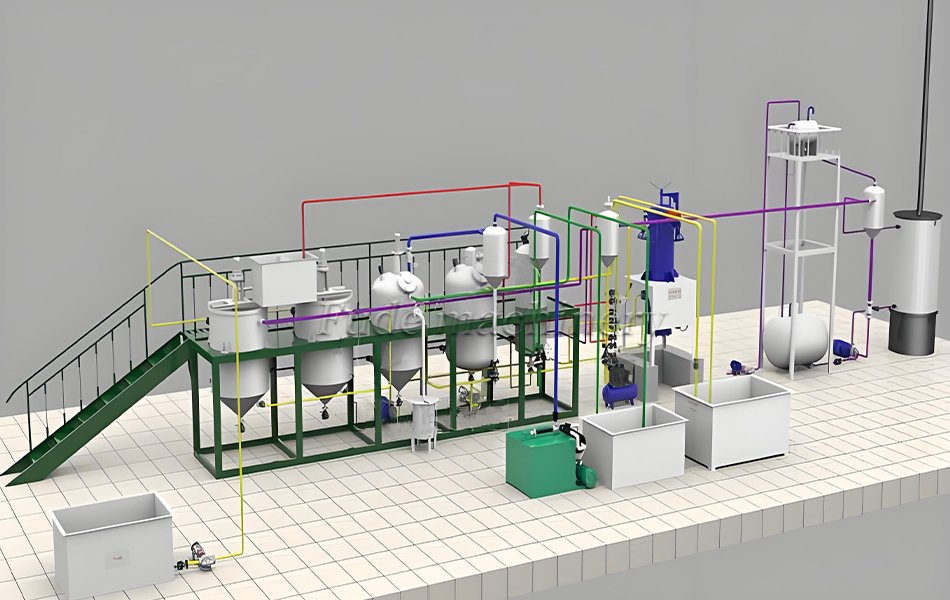

Are you struggling with the complexities of purifying used oils? Do you find it hard to achieve consistent quality or high yield? I am Fude Machinery. My company specializes in oil processing equipment. I understand the unique challenges in used oil refining processes. These processes are vital for sustainability and resource recovery.

Tackling High Impurity Levels in Used Oil: What Are Effective Strategies?

Used industrial or cooking oils are high in impurities—water, solids, metals, degraded acids included. Removing these is critical: it protects equipment, ensures product quality, and enables efficient refining.

Our company prioritizes this core step. Our multi-stage purification approach (mechanical separation, chemical treatment, advanced filtration) targets specific contaminants for thorough cleaning.

Our oil processing equipment delivers ultra-pure feedstock, laying the foundation for high-quality refined products and smooth downstream operations.

Removing Water and Particulates Effectively?

Removing water and solid particulates from used oil is key to preventing corrosion, protecting equipment, and boosting refining efficiency. Our integrated system (gravity settling + centrifugal separation + micron filtration) eliminates all contaminants, delivering a clean oil stream for smooth, efficient refining.

Practical tips and advice for you:

- Drain tank sediment/water regularly to avoid buildup

- Clean/replace filters per differential pressure limits

- Preheat oil gently for better separation efficiency

Case Highlight:40% less pump maintenance + better feed oil quality — achieved by a used engine oil refiner with our pre-filtration and centrifugal separation system.

Neutralizing Acids and Contaminants?

Neutralize acidic and chemical contaminants in used oil to protect equipment and ensure product stability. Our precision alkaline treatment + activated adsorption system delivers clean, stable oil for efficient refining.

Practical tips and advice for you:

- Auto-dose neutralizers to prevent over/under-treatment

- Monitor pH continuously for target neutralization endpoint

- Optimize mixing for full oil-chemical contact

Case Highlight:90%+ acid number reduction for used hydraulic fluid refining — achieved with our automated neutralization (precision caustic dosing) unit, meeting industrial specs.

Achieving Desired Oil Quality: Color and Odor?

After initial impurity removal, the key challenge in used oil refining is improving color and eliminating odors—critical for market acceptance and expanding product applications.

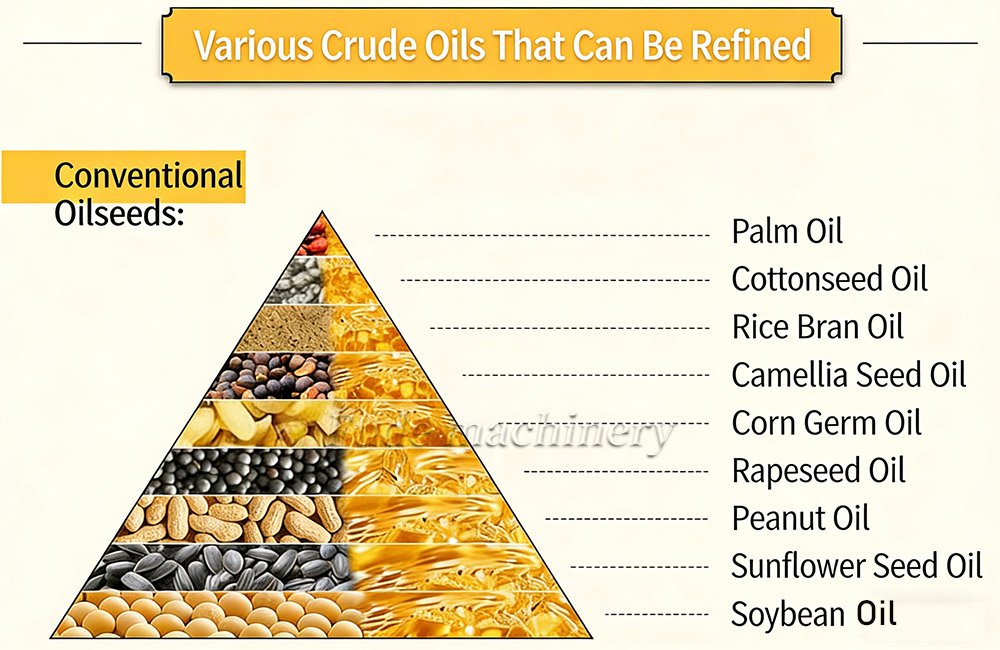

Our specialized decolorization and deodorization units target stubborn pigments and volatile compounds in used oils. Unit selection is tailored to the raw oil’s initial quality and desired final specs (e.g., biodiesel from cooking oil has different color requirements than re-refined industrial lubricants). Our equipment ensures these stages are effective and energy-efficient, yielding a clean, odorless, visually appealing refined oil.

Enhancing Decolorization for Clearer Oil?

Used oil’s dark pigments are tougher to remove than crude oil’s—our advanced decolorization units use activated earth/carbon and precise process control to deliver bright, clear refined oil that stands out in the market.

Practical tips and advice for you:

- Lab-test adsorbents for ideal oil compatibility

- Ensure sufficient oil-adsorbent contact time

- Use pressure leaf/plate filters for full adsorbent separation

Case Highlight:Steady ASTM D1500 color index 2.0 for industrial oil re-refining, achieved with our vacuum decolorization system + optimized activated carbon—unlocking new market opportunities.

Eliminating Off-Odors with Advanced Deodorization?

Used oils have foul odors from degradation-derived volatile compounds—removing these is critical for marketable refined oil.

As the final refining step, deodorization uses high-vacuum steam stripping at elevated temperatures to eliminate odor-causing substances like free fatty acids. Used oil deodorization demands more robust equipment than virgin oil processing, and our advanced units feature optimized steam distribution, efficient heat recovery, and powerful vacuum systems for thorough odor removal. The process delivers neutral-smelling oil with enhanced oxidative stability and longer shelf life, meeting strict quality standards for end applications.

Practical tips and advice for you:

- Max vacuum for better deodorization

- Precise steam control to save energy & ensure efficacy

- Rapid post-treatment cooling to avoid re-oxidation

Case: My continuous deodorization column with advanced vacuum system eliminated the frying smell in used cooking oil biofuel, improving biodiesel feedstock quality.

Optimizing Separation Techniques?

Optimizing separation boosts oil recovery, raising yield and profitability in used oil refining.

My oil refining equipment uses advanced tech—centrifuges, optimized filters, neutralization units—to minimize oil loss in separation steps, recovering more oil and boosting efficiency and profitability.

Practical tips and advice for you:

- Install decanter centrifuges for efficient sludge de-oiling, optimize filter press cycles for maximum oil drainage, and use gravity separators to recover trace oil from wastewater.

Frequently Asked Questions

Question 1:

Challenges in used oil refining: high impurities, inconsistent raw materials, achieving desired color/odor, ensuring yield, managing waste, and maintaining equipment. My solutions tackle these directly.

Question 2:

Improve oil color by optimizing decolorization with quality bleaching earth, precise temperature/mixing controls, advanced filtration, and possibly a second decolorization step.

Question 3:

Achieving food-grade from used oils is rare and depends on source/contamination. My equipment focuses on industrial, biofuel, or non-edible uses, meeting strict purity standards.

Question 4:

Common byproducts: water, solids, spent bleaching earth, and acidic waste. My systems minimize volume and simplify waste management.

Question 5:

Fude Machinery provides customized equipment, expert consultation, plant design, and support to optimize efficiency and quality in your used oil refining.

Summary and Recommendations

Successfully refining used oil demands a strategic approach: tackle impurities, ensure quality (color/odor), minimize oil loss, and maintain reliable equipment. Invest in advanced technology and partner with experienced manufacturers like Fude Machinery. Assess your oil source and product needs, choose tailored equipment for efficiency and longevity, and rely on our quality support for a profitable, sustainable refining venture.

Are you ready to optimize your used oil refining processes for better results?

Contact Fude Machinery’s expert team today. Get a custom solution designed just for your business. Let us help you achieve your production goals.

Related recommendations

-

Application scenarios of tea seed peeling machine in oil tea fruit processing

469Oil tea fruit processing, tea oil production, deep processing of agricultural products, scientific research and teaching, family and small-scale farms

View details -

What are the key differences between cold pressed oil and hot pressed oil?

494I will explain the main differences between cold pressed oil and hot pressed oil. This information helps your business choose the right oil extraction equipment. Fude Machinery specializes in efficient oil processing solutions. My goal is to help...

View details -

Why Is Soybean Oil So Popular Globally?

417Soybean oil is a very common cooking oil around the world. Many people use it every day in kitchens and in food production. Its widespread use is no accident. We at Fude Machinery understand the full journey of soybean oil production. We make the...

View details -

Extraction of Oil from Soya Beans

605The edible oil produced from soybeans is light, clean, and flavorful. This makes it more popular and loved by many people. Soybean oil is composed of 60% polyunsaturated fat and 24% monounsaturated fat, which combine to form a heart healthy oil....

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business