How to Make Vegetable Oil: Your Complete Guide?

Making vegetable oil requires specific steps and reliable equipment. We at Fude Machinery understand this process well. We design and manufacture comprehensive oil processing equipment in Zhengzhou, China. This includes everything from initial seed preparation to final oil refining. We want to help you understand how to make high-quality vegetable oil for food or industrial use. Our goal is to make this process simple for you, no matter your scale.

Last Updated: May 2025 | Estimated Reading Time: 10 minutes

Table of Contents

- What Preparation Do Oilseeds Need Before Pressing?

- Why Pre-Treatment Boosts Oil Yield?

- How Do Different Oil Presses Extract Oil Efficiently?

- What Steps Are Involved in Refining Crude Oil?

- Why Choose a Full Processing Line from Fude Machinery?

- What Are the Latest Trends in Vegetable Oil Production?

- frequently asked questions

- Summary and Suggestions

- About Fude Machinery

What Preparation Do Oilseeds Need Before Pressing?

Oilseed preparation is a critical first step. It makes sure you get the most oil from your raw materials. This also helps the pressing process run smoothly. We call this the pretreatment phase. It gets your oilseeds ready for extraction.

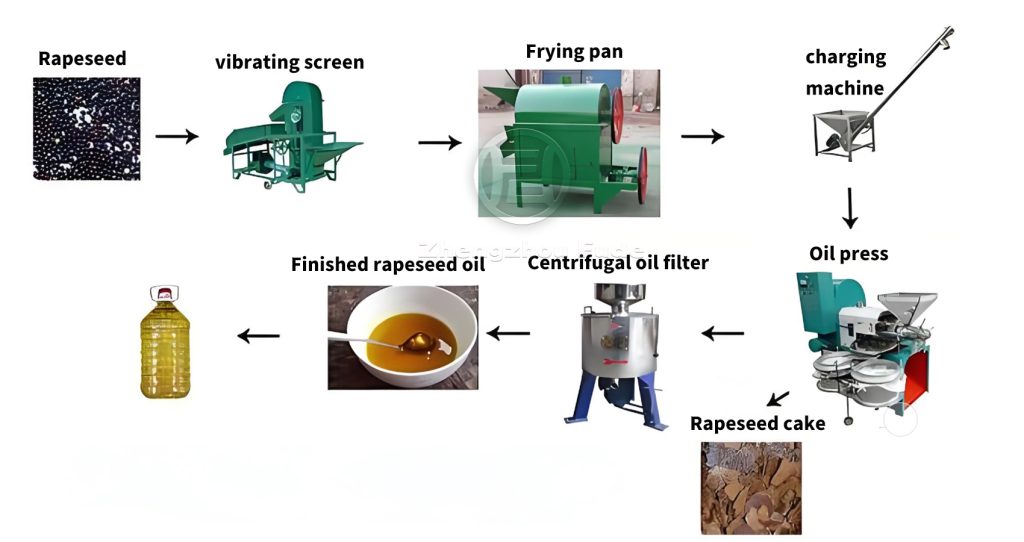

When you prepare oilseeds, you start by cleaning them. This removes dirt, stones, and other impurities. We then typically dehull them if needed. For example, sunflower seeds and cottonseeds have shells that must come off. Next, we crush the seeds into smaller pieces. This increases their surface area. It helps the oil come out more easily during pressing.

After crushing, many oilseeds go through a cooking or roasting step. This process breaks down cell walls. It also denatures certain proteins. This makes the oil flow more freely. Our roaster machine and steamer equipment are perfect for this step. For example, roasting peanuts before pressing significantly increases oil yield and improves the flavor of the oil. This prepares the material for an efficient oil extraction equipment process.

Why Pre-Treatment Boosts Oil Yield?

Pre-treatment directly impacts how much oil you get. It also affects the quality of the final oil. When you properly prepare seeds, less oil stays in the residue. This means more oil for your business. For example, properly cooked soybeans yield more oil than raw ones. The heat makes the oil flow better. It reduces the stickiness inside the seeds.

This leads to a higher extraction rate. This step is a small investment that offers big returns. It prevents blockages in your oil press machine too.

| Pre-Treatment Step | Purpose | What it means to you in practice |

|---|---|---|

| Cleaning & Dehulling | Remove impurities, improve oil purity | Higher quality oil, less wear on machines |

| Crushing | Break down cell structure, increase surface area | Easier oil release, better extraction efficiency |

| Cooking & Roasting | Denature proteins, reduce viscosity | Higher oil yield, improved oil flavor |

Practical tips and suggestions for users

- For maximum yield: Use our roaster machine for seeds like peanuts or sesame. It helps release more oil.

- For cleaner oil: Always use our cleaning and screening equipment first. This removes unwanted particles.

- For consistent results: Control the moisture content before pressing. Our equipment helps maintain optimal levels.

practical cases: One of our clients in Africa saw a 10% increase in vegetable oil yield after implementing our complete pretreatment line for sunflower seeds. They moved from manual cleaning and basic crushing to our automated system. The consistency of their input material greatly improved their pressing efficiency.

How Do Different Oil Presses Extract Oil Efficiently?

After proper preparation, the oilseeds are ready for extraction. Oil extraction equipment is the core of any oil mill. We offer several types of presses. Each press works best for different needs. The main goal is to physically squeeze oil from the seeds.

We provide single screw oil press machines. These are popular for small to medium-scale operations. They are easy to use and maintain. They work by using a rotating screw that applies continuous pressure to the seeds. This pushes the oil out through small gaps. We also have double screw oil press machines. These are for larger capacities.

They offer higher efficiency and continuous operation. For smaller batches or specialty oils like olive oil, our hydraulic oil press is ideal. It uses hydraulic pressure to extract oil. This method is often chosen for its ability to preserve the oil’s natural qualities. All our presses are designed for durability and high output. They ensure maximum oil recovery from various oilseeds.

Which Oil Press Suits Your Needs Best?

Choosing the right oil press machine depends on your specific goals. Consider the type of oilseed you process. Also think about your desired production capacity. Small individual farmers often prefer a simple and robust single screw oil press. It is cost-effective and easy to operate.

Medium-sized oil mills might need a double screw oil press. It offers higher throughput and better automation. For high-value specialty oils, a hydraulic oil press might be the best choice. It often produces a higher quality oil. Our experts can help you select the perfect machine for your oil mill plant.

| Oil Press Type | Ideal for | Key Advantages |

|---|---|---|

| Single Screw Oil Press | Small-medium scale, diverse seeds | Easy to operate, cost-effective |

| Double Screw Oil Press | Large scale, continuous operation | High throughput, higher efficiency |

| Hydraulic Oil Press | Specialty oils, high purity | Preserves oil quality, cold pressing option |

Practical tips and suggestions for users

- For diverse seeds: A single screw oil press is versatile for different seed types.

- For high volume: Consider a double screw oil press for continuous, large-scale production.

- For specific oil types: Use a hydraulic oil press for delicate oils like flaxseed or almond oil.

practical cases: A client in Vietnam initially used a batch-type press for rice bran. After consulting with us, they upgraded to a continuous double screw oil press. Their daily processing capacity doubled, and labor costs reduced by 30%. This significantly boosted their overall profitability.

What Steps Are Involved in Refining Crude Oil?

After extraction, you get crude oil. This crude oil contains impurities. These impurities affect its taste, smell, color, and shelf life. Oil refining equipment removes these impurities. This makes the oil suitable for consumption or specific industrial uses. The refining process has several key stages.

The first stage is degumming. This removes phospholipids and other gummy substances. We use hydration or acid degumming for this. Next is deacidification. This removes free fatty acids. These cause rancidity. This can be done physically or chemically. Then comes decolorization, also called bleaching. This step removes pigments that give the oil an unwanted color. We use activated clay for this. Finally, deodorization removes unwanted odors and volatile compounds. High-temperature steam distillation is usually employed here.

Our refinery machine units handle each of these steps efficiently. We offer both batch oil refining systems for smaller volumes and continuous oil refining lines for large-scale operations. This ensures your edible oil production meets all quality standards.

Why Is Oil Refining Essential for Quality?

Refining is not just about making the oil look good. It’s about making it safe and stable for use. Impurities can cause oil to spoil quickly. They can also affect the flavor. For instance, free fatty acids can make oil taste bitter. Pigments can make it look unappetizing. Deodorization removes undesirable smells. It ensures a neutral taste. This is crucial for cooking oils. Properly refined oil has a longer shelf life. It also has better cooking performance. Our oil refining equipment ensures your product meets market demands. It also protects your brand reputation.

| Refining Stage | Purpose | Benefits for You |

|---|---|---|

| Degumming | Remove phospholipids | Prevents cloudiness, improves stability |

| Deacidification | Remove free fatty acids | Extends shelf life, improves taste |

| Decolorization | Remove pigments | Improves appearance, removes harmful substances |

| Deodorization | Remove odors & volatiles | Neutral taste, suitable for cooking |

Practical tips and suggestions for users

- For food-grade oil: Always include a full refining process. This ensures safety and quality.

- For cost-effectiveness: Consider our batch oil refining unit for smaller production needs.

- For high volume: Our continuous oil refining lines offer automation and efficiency.

practical cases: A mid-sized oil mill in Brazil previously sold crude soybean oil. After installing our integrated oil refining equipment, they started producing refined, bottled edible oil. Their profit margins increased by 40% within a year due to the higher value of the refined product.

Why Choose a Full Processing Line from Fude Machinery?

We at Fude Machinery do more than just sell individual machines. We design and provide entire processing production lines. This means you can get a complete solution from one trusted supplier. We handle everything. This includes the initial design and equipment manufacturing. We also manage installation, debugging, and staff training. Our oil mill plant solutions are comprehensive.

Choosing a full line from us simplifies your project greatly. You do not need to coordinate with multiple vendors. This saves you time and reduces potential problems. Our team ensures all equipment works seamlessly together. This optimizes efficiency and output. We can custom-design a solution for you. This includes specific raw materials, desired output, and space constraints. Whether you need a complete vegetable oil extraction and refining plant or a specialized oil processing line, we have the expertise. We offer full-service support every step of the way. Our direct sales model also means you get competitive pricing. We have shipped our products to over 120 countries. This shows our global reach and proven reliability.

How Our Full-Service Approach Benefits You?

Our full-service approach gives you peace of mind. You work with one dedicated team. We understand your needs from start to finish. This leads to a smoother project. We provide training for your staff. This ensures they can operate the new equipment confidently.

Our after-sales support means we are always there to help. This reduces downtime. It keeps your operations running. We help you achieve your production goals. Our long history as manufacturers means deep industry experience. This expertise is a direct benefit to you.

| Aspect of Service | What We Do For You | Your Direct Benefit |

|---|---|---|

| Customization | Design line for your specific needs | Optimal performance, less waste |

| Manufacturing | Produce high-quality, durable equipment | Reliable operation, long lifespan |

| Installation & Debugging | Set up and test the entire line | Smooth start-up, minimal issues |

| Training & Support | Train your staff, offer after-sales help | Confident operation, reduced downtime |

Practical tips and suggestions for users

- For new ventures: Opt for a full production line. This ensures all parts fit and work together.

- For efficiency: Our integrated lines are optimized for maximum throughput.

- For global buyers: Our global presence means we understand international logistics and support.

practical cases: A new startup in Nigeria wanted to build a palm kernel oil processing plant. They chose our complete oil mill plant solution. We designed the layout, manufactured the equipment, and supervised installation. Their plant started production on schedule. They achieved full capacity quickly.

What Are the Latest Trends in Vegetable Oil Production?

The vegetable oil industry is always changing. We keep up with the latest trends. This ensures our oil processing equipment remains cutting-edge. Two main areas of focus are sustainability and automation. These trends impact how we design and build machinery. They also affect how you operate your business.

Sustainability is a growing concern. Consumers want oils produced in an environmentally friendly way. This means less waste and less energy use. Our equipment aims for higher oil extraction rates. This leaves less oil in the cake. It makes the process more efficient. We also focus on energy-saving designs. Automation is another big trend. Modern plants want less manual labor. They want more consistent results. Our new machines integrate advanced controls. They allow for more automated processes. This includes temperature control in roaster machines and automatic feeding systems. These advancements help you meet future market demands. They also improve your competitive edge.

Latest Developments Overview

- Energy Efficiency: New designs reduce power consumption in pressing and refining.

- Smart Automation: Integrated sensors and controls for precise process management.

- Waste Valorization: Technologies to turn oilseed meal into valuable by-products.

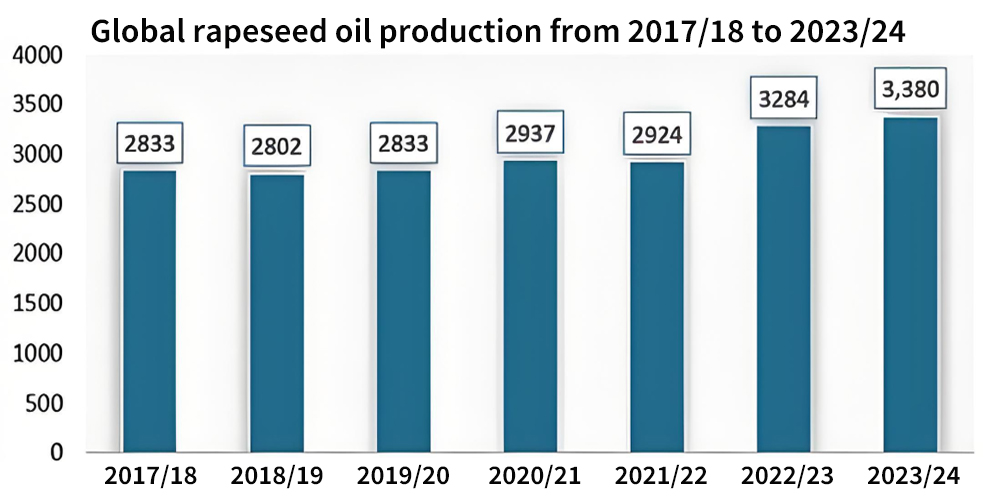

MARKET INSIGHT: The global demand for healthy, sustainable vegetable oil is increasing. Markets in developing countries show strong growth. This is especially true for locally produced oils. Automation helps these regions scale up production quickly. It makes their products competitive globally. We see continued demand for modular systems. These systems can expand easily. This helps businesses grow with demand.

frequently asked questions

Question 1: How much space do I need for an oil mill plant?

The space needed depends on your desired capacity and equipment types. A small single screw oil press setup might need only 50-100 square meters. A full continuous oil refining line can require thousands. We provide detailed layout designs based on your specific requirements.

Question 2: Can your equipment process different types of oilseeds?

Yes, our oil extraction equipment is versatile. It can process a wide range of oilseeds. This includes soybeans, peanuts, sunflower seeds, palm kernels, and more. Our customized solutions ensure optimal performance for your specific raw materials.

Question 3: What kind of after-sales support do you offer?

We offer comprehensive after-sales support. This includes installation guidance, debugging, training for your operators, and ongoing technical assistance. We want to ensure your oil processing equipment runs smoothly for years.

Question 4: How long does it take to get a complete oil processing line installed?

Installation time varies. It depends on the complexity and size of the line. Typically, a complete oil mill plant can be installed and debugged within a few weeks to a couple of months. Our team works efficiently to get you up and running.

Summary and Suggestions

Making vegetable oil involves a clear process. It starts with careful oilseed preparation. Then, you need efficient oil extraction. Finally, you must refine the crude oil. We covered each key step in detail. We also highlighted the essential oil processing equipment for each stage. We talked about why pre-treatment, the right press, and proper refining are crucial.

We recommend you first assess your specific needs. Think about your raw materials and target output. Consider your budget. Then, look for a partner who offers comprehensive solutions. Choose a supplier with strong technical expertise. This supplier should provide full-service support. This includes design, manufacturing, installation, and after-sales care. We are here to help you every step of the way. Contact us today. We can discuss your project. We will help you find the best solution for your vegetable oil production needs.

About Fude Machinery

We are Fude Machinery. We are a leading Chinese manufacturer of oil processing equipment. We are located in Zhengzhou. Our company specializes in B2B solutions. We offer a full range of products. This includes oil extraction equipment, oil refining equipment, and complete production lines. Our facilities are well-equipped. We implement strict quality control. We have exported to over 120 countries. We are committed to customer satisfaction. We help you achieve efficient and high-quality oil production.

Contact Us Today to Discuss Your Oil Processing Needs!

Related recommendations

-

Advantages and disadvantages of oil press

682As a device that converts oil crops into edible oil, the oil press has its unique advantages and disadvantages. Please refer to the specific introduction

View details -

What is a centrifugal oil filter

609Centrifugal oil filter is an efficient, economical, and safe oil purification equipment, widely used in multiple fields

View details -

What is the difference between hydraulic oil press and screw oil press

452Hydraulic oil press and spiral oil press are two common oil crop oil pressing equipment, which have significant differences in pressing principles, applicable oil materials, oil yield and efficiency, equipment advantages and disadvantages, etc.

View details -

How to find an affordable oil press for a small oil mill?

496Choosing the right machine feels like a big task. Many options exist, and it's hard to know where to start. Don't worry, we build these machines, and we want to help you succeed. Let's break down the key questions you should ask to find the perfe...

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business