How to refine sunflower seed oil using a refining machine?

Are you seeking to produce premium, edible sunflower seed oil from crude oil? Do you want to understand the machinery that makes this possible? I am Fude Machinery. My company specializes in oil processing equipment. I can help you. I design and build top-tier sunflower seed oil refining machinery. My goal is to transform raw sunflower oil into a safe, delicious, and marketable product for your business.

What Exactly is Sunflower Seed Oil Refining Machinery?

Sunflower seed oil refining machinery is a specialized system designed to remove impurities—such as gums, free fatty acids, pigments, waxes, and odor-causing compounds—from crude oil extracted through pressing. This process transforms raw oil into a safe, stable, and visually appealing edible product suitable for cooking and food applications.

Acting as the core of any edible oil processing plant, this machinery works like water purification, systematically eliminating contaminants that could cause cloudiness, off-flavors, or spoilage. The seamless, step-by-step system moves oil through various stages—chemical mixing, solid filtration, and vacuum heating—to ensure the final product is clear, neutral in taste, and has a long shelf life, ready for the market. This complete solution handles the full transformation, regardless of the raw oil’s initial state.

Essentially, sunflower seed oil refining machinery is not just one machine. It is a complete system. It is carefully engineered. Each piece of equipment plays a crucial role. From the initial holding tanks to the final polishing filters, every component is vital. My machines are built to handle different capacities. Whether you are a small factory producing a few tons a day, or a large industrial plant, I have solutions for you.

I design these systems to be efficient. They minimize waste. They maximize oil yield. This means more profit for your business. My engineers focus on durability. They make sure the machinery runs smoothly for a long time. They also focus on ease of use. This simplifies your operations. This comprehensive approach is what Fude Machinery brings to the table. It provides you with reliable and high-performing oil processing equipment.

Why is Refining Sunflower Seed Oil Important?

Refining sunflower seed oil is a critical step for your business. It is not an optional extra. It directly impacts your product’s quality, market value, and safety. Without refining, crude sunflower seed oil contains too many impurities. These impurities limit its use and reduce its appeal.

Unrefined crude sunflower seed oil contains a host of substances. These make it unsuitable for direct consumption. These include phospholipids, which cause cloudiness and reduce shelf life. It also has free fatty acids (FFAs), which lead to a bitter taste and low smoke point. Pigments give the oil an unappealing dark color.

Volatile compounds cause unpleasant odors and flavors. Waxes, if present, can make the oil appear cloudy when cooled. If you sell unrefined oil, you limit your market greatly. You can only target niche industrial uses. You also risk customer dissatisfaction. By investing in my sunflower seed oil refining machinery, you transform your product. You elevate it to a standard that is safe, palatable, and visually appealing.

This means your oil will meet national and international food safety standards. This opens up larger markets for you. These markets include supermarkets, restaurants, and food manufacturers. This shift from crude to refined oil significantly increases your product’s value. It positions your business as a producer of high-quality goods. This is a direct path to higher profit margins and sustained business growth.

Refining drastically extends sunflower seed oil’s shelf life: removing impurities prevents rancidity and degradation, cutting spoilage and waste. For your business, this means lower losses, improved inventory management, longer storage times, wider distribution reach, and less pressure for immediate sales.

Refined sunflower seed oil is also highly versatile—it works seamlessly in diverse food products (e.g., fried snacks, salad dressings) without altering flavor or appearance, appealing to a broader customer base. Our oil processing equipment guarantees your refined oil consistently meets these strict quality standards, building your brand’s reputation for reliability and letting you sell your oil confidently worldwide.

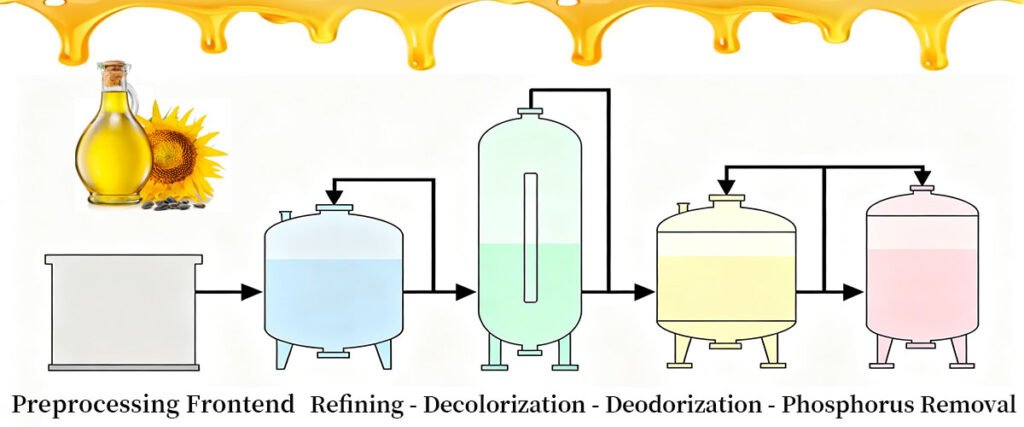

What are the Essential Steps in Refining Sunflower Seed Oil?

Understanding sunflower seed oil refining steps aids in selecting machinery and optimizing processes. Refining usually involves five steps to turn crude oil into high-grade edible oil:

1.Degumming: Removes hydratable and non-hydratable phospholipids using water or dilute acid (e.g., phosphoric acid). These are separated by centrifugation, yielding degummed oil and gums for lecithin production.

2. Degumming: Removes hydratable and non-hydratable phospholipids using water or dilute acid (e.g., phosphoric acid). These are separated by centrifugation, yielding degummed oil and gums for lecithin production.

3. Deacidification: Eliminates free fatty acids (FFAs) to avoid reduced smoke point and off-odors. Chemical refining uses caustic soda to convert FFAs into soapstock, separated by settling/centrifugation. Physical refining uses high-temperature vacuum distillation with steam stripping, often combined with deodorization, for a chemical-free, cost-saving approach.

4. Decolorization: Removes pigments (e.g., chlorophyll, carotenoids) for a clear appearance. Activated bleaching clay is mixed with oil under vacuum and high temperature to adsorb pigments, then separated by filter presses.

5.Deodorization: Removes residual volatile compounds. Oil is heated to 220-260℃ with steam injection and high vacuum to vaporize odorous substances, then rapidly cooled to prevent re-oxidation, resulting in odorless oil.

What Main Equipment Does Sunflower Seed Oil Refining Need?

My company, Fude Machinery, offers a full suite of specialized sunflower seed oil refining equipment, tailored to your capacity and budget.

Main equipment includes tanks, filters, vacuum systems, and heating units. For degumming and chemical deacidification, stainless steel agitated refining tanks are used for precise mixing of oil with water or alkali. Physical deacidification employs a tall deacidification column for simultaneous deacidification and deodorization.

Decolorization involves decolorization tanks to blend oil with activated clay and filter presses to separate spent clay, yielding lighter-colored oil. Deodorizers, high-temperature vacuum-sealed vessels, efficiently remove odors through steam stripping. A vacuum system maintains low pressure for effective impurity removal and oil protection.

Heat exchangers, thermal oil furnaces, or steam boilers supply necessary heat, while storage tanks hold crude and refined oil. For winterization, crystallization tanks and extra filter presses are utilized.

Here’s a brief overview of the main equipment and their benefits.

| Equipment Type | Key Function | Your Benefit |

|---|---|---|

| Refining Tanks | Degumming, Deacidification | Removes impurities, improves oil purity |

| Decolorization Tank | Pigment Removal | Makes oil clearer and more appealing |

| Filter Press | Solid-Liquid Separation | Ensures sparkling, clean refined oil |

| Deodorizer | Odor and Flavor Removal | Produces neutral-tasting, odorless oil |

| Vacuum System | Pressure Control | Enhances refining efficiency, protects oil |

| Heating System | Temperature Management | Ensures optimal process conditions, energy control |

| Crystallization Tanks | Wax removal (winterization) | Guarantees clear oil at cold temperatures |

| Storage Tanks | Oil Storage | Manages raw and finished product inventory |

Practical tips and advice for you:

- Material Quality: Always choose equipment made from food-grade stainless steel. This prevents contamination and ensures longevity.

- Automation Level: Consider semi-automatic or fully automatic sunflower seed oil refining machinery based on your budget and labor availability. Semi-automatic is often a good balance for medium capacity.

- Energy Efficiency: Look for equipment with energy-saving designs. This includes efficient heat recovery systems and optimized vacuum pumps.

Actual case: I supplied a comprehensive refining line to a client in Ukraine. He wanted to produce high-quality sunflower seed oil for local and export markets. My recommended modular semi-automatic sunflower seed oil refining machinery helped him achieve his goals. His oil quickly gained market acceptance. This led to rapid expansion.

How Do My Machines Ensure High Quality and Efficiency?

At Fude Machinery, ensuring high quality and efficiency in sunflower seed oil refining is our core principle, as your success hinges on both. Our machinery is engineered to deliver premium results while keeping operating costs low.

High Quality: Our equipment ensures precision through advanced control systems, often using PLCs, to accurately manage temperature, pressure, chemicals, and flow rates at every stage. This minimizes human error, ensuring consistent product quality. For instance, precise alkali use in deacidification prevents unwanted saponification, while exact temperature and clay dosage in decolorization optimize pigment removal and reduce oil loss. Using food-grade stainless steel for oil-contacting parts prevents contamination, ensuring purity and meeting strict food safety standards to satisfy customer demands.

Efficiency: Our machinery is designed for energy conservation, waste reduction, and maximized oil yield. Efficient heat exchangers recover heat from hot oil to preheat crude oil, cutting energy consumption. High-efficiency vacuum systems maintain optimal pressure with minimal power for successful deodorization. We minimize oil losses with effective centrifuges and optimized filter press operations. Our designs support continuous or semi-continuous operations, maximizing throughput, reducing variations, and minimizing downtime.

Choosing our oil processing equipment means an effective and economical system that lowers production costs and boosts profitability, designed for long-term value. For more details, explore comprehensive guides on refinery processes.

What Are the Benefits of Choosing Fude Machinery for Your Refining Needs?

Choosing Fude Machinery for your sunflower seed oil refining machinery offers numerous benefits. I aim to be your trusted partner, delivering complete solutions and exceptional value.

A major advantage is my comprehensive equipment range, covering everything from pre-treatment to final packaging. This one-stop solution ensures seamless integration and avoids the hassle of multiple vendors. I provide various oil extraction machines, refining, filtering, and drying equipment, and can design entire processing lines for different capacities.

Customization is another key benefit. Recognizing each client’s unique needs—whether related to raw materials, capacity, or space—my expert team creates tailored solutions for optimal performance and efficiency.

My full-service support includes initial consultation, plant design, equipment manufacturing, installation, commissioning, personnel training, and excellent after-sales maintenance, ensuring support at every step.

As a direct manufacturer, my factory direct sales model offers competitive pricing without compromising quality, boosting your profitability. With global reach, I’ve exported to over 120 countries, understanding diverse market demands and ensuring reliable, high-quality machinery.

My long-standing industry experience and professional R&D team continuously innovate, incorporating the latest advancements to provide cutting-edge solutions. My goal is to help you establish a successful, profitable, and sustainable edible oil business. For more details, explore my small edible oil refinery machines and general oil refinery machine information.

Frequently Asked Questions

Question 1: Why refine sunflower seed oil?

Refining removes impurities like phospholipids, free fatty acids, pigments, and waxes, ensuring the oil is clear, stable, safe, and has a longer shelf life and better taste. It meets food safety standards, expands market reach, and increases product value.

Question 2: What capacities does Fude Machinery offer?

Fude Machinery provides a wide range, from small-scale batch systems for new businesses to large-scale continuous production lines for industrial use. We customize equipment to match your exact processing needs and daily output goals.

Question 3: Are Fude’s machines easy for new users?

Yes, our systems feature semi-automatic or automated controls for simple operation. We offer full staff training on operation and maintenance, ensuring efficient and safe use, even for those new to refining.

Question 4: How does Fude ensure equipment quality?

We prioritize quality by using food-grade stainless steel and enforcing strict production controls. Our R&D team ensures robust design and performance, meeting international standards. Our global export to over 120 countries reflects our commitment to quality.

Question 5: What maintenance is required?

Regular maintenance includes daily checks, weekly lubrication, monthly seal/filter inspections, and frequent tank/pipeline cleaning to prevent residue. Annual overhauls may involve electrical checks and component replacements. Fude provides manuals and training for routine care.

Summary and Recommendations

Understanding sunflower seed oil refining machinery is key to producing high-quality edible oil. This comprehensive system removes impurities and transforms crude oil into a valuable product, crucial for quality, market value, and safety. My machines ensure efficiency and quality through precise control and robust design.

I recommend assessing your specific needs—processing capacity, budget, and target oil quality—and partnering with a trusted manufacturer like Fude Machinery. I offer customized solutions, full-service support, and competitive pricing, ensuring reliable, high-performing equipment to help you succeed in the edible oil market.

About Fude Machinery

I am Zhengzhou Fude Machinery. I am a professional oil processing equipment manufacturer in China. I specialize in the research and production of various oil extraction machines. I focus on B2B business. My products are mainly used for food oil, refined oil, and other oil applications. My facilities are well-equipped. I ensure excellent quality control at all stages. I export my products to over 120 countries. I am committed to complete customer satisfaction.

Are you ready to elevate your sunflower seed oil production with advanced refining machinery?

Contact Fude Machinery’s expert team today. Get a custom solution designed just for your business. Let us help you achieve your production goals.

Related recommendations

-

Comparing Chemical and Physical Oil Refining?

689Crude oil holds many impurities. You need clean, pure oil. Refining gives you safe, high-quality oil. Chemical refining uses alkali to remove free fatty acids. Physical refining uses high temperature steam distillation. Choosing one depends on ...

View details -

Soybean oil Extraction with Oil Pressing Machine

430Soybean oil is one of the major vegetable oils in the world, occupying a significant share in the global edible oil market, and the global production of soybean oil is usually more than tens of millions of tons. China, the United States, Brazil a...

View details -

What is the purpose of a tea seed sheller

609The tea seed peeling machine is mainly used for processing oil tea fruits, such as impurity removal, peeling, and sorting

View details -

What are the characteristics and advantages of the refining machine

490Edible oil refining machine is a key equipment used to improve the quality and stability of edible oil. It deeply processes crude oil through a series of complex process steps to remove impurities, acidic substances, pigments, and odors, thereby p...

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business