Plant oil production line

Launch a small-scale oil processing business

Vegetable oil production line is open for producing natural and qualitative vegetable oil from high quality seeds of different kind of plants, such as sunflower, sesame, soybean, palm, cotton, peanut, rape and others.

Pre-treatment process

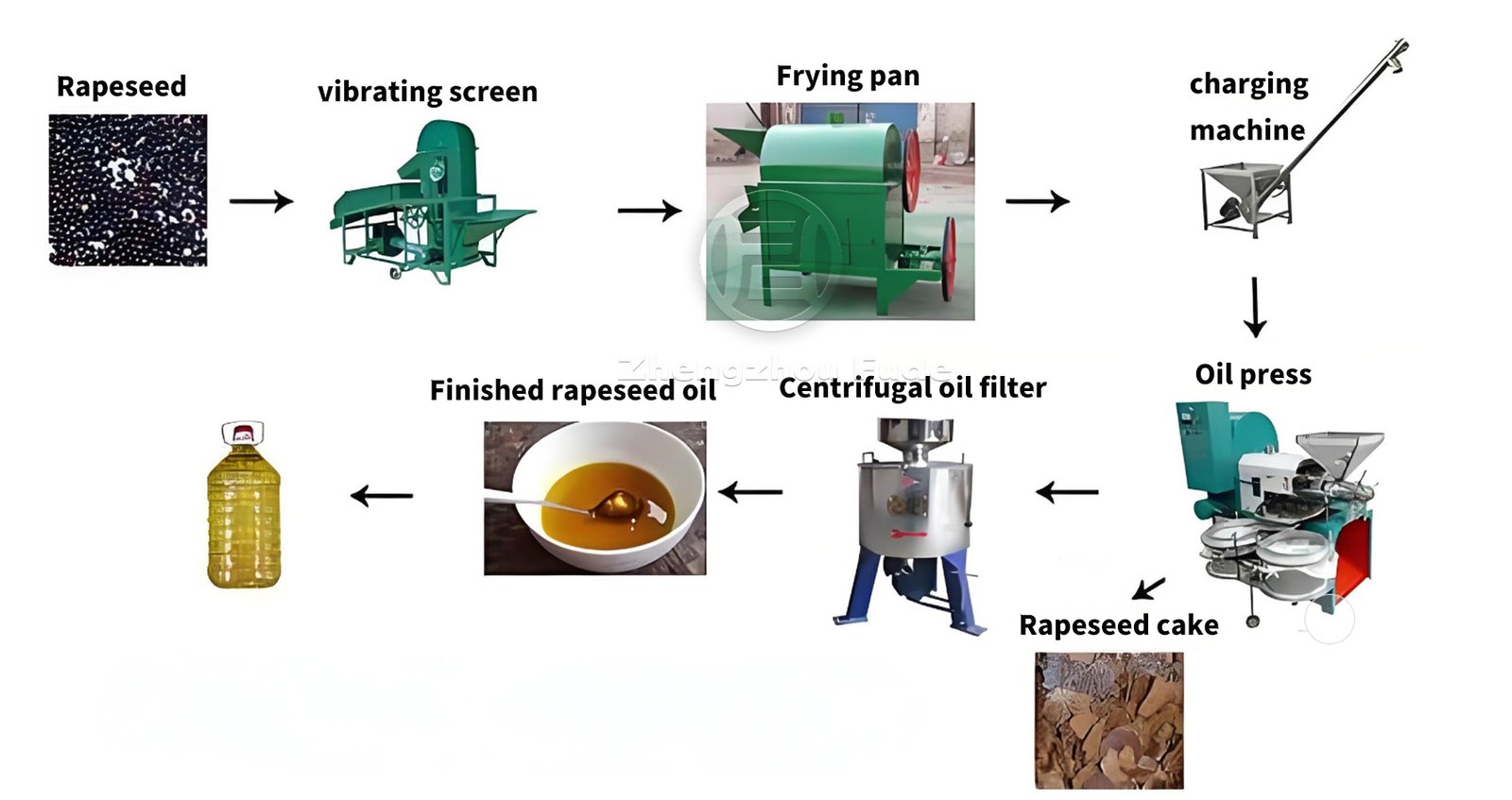

- On the first stage the seeds are going through cleaning, hulling, crushing, flaking, softening, cooking, pressing and filtering. For this process different types of pressing systems are used, according to a volume of output you need and also according to a type of seeds you are using to get certain oil. The oil pressing system as a rule contains a cleaning sieve, screw elevators, a cooker, a presser, a filter and a refiner. It all depends on a model and design, which different companies can provide you. All seeds are going to a cleaning sector and after step by step to each mentioned sector to be ready for a next stage.

- The second stage includes extracting, removing the solvent nature, evaporating, stripping and solvent recycling. Extraction process is the process, which means the separation oil from seeds. The pre-processed seeds are treated in a multistage counter current process with solvent. Then oil and solvent are separated by distillation. The solvent going into the extraction recycle process and the crude oil is ready for a next step. This process will keep production safety and provides a good quality.

- The last stage provides degumming, discoloring, deodorization, removing wax, fractionation etc. De-waxing section is optional. On the stage of degumming the oil separated from sand, after which it gets to be free from free-fatty acids and color pigments. Then the smell and odor are removed from the oil, because many seeds have special odors and smells, which many people don’t like. So, that will allow getting a high quality production of oil.

Small scale vegetable oil production line is very comfortable for small family business. For that line it is required only 2-3 persons. This line requires also a smaller space for machines, which are oil press, oil filter, cooker and so on, of different designs from different producers, but making all these three processes, same as big plants are doing, and it will give a wonderful output.

Small scale vegetable oil production line is a wonderful opportunity to get a high quality vegetable oil inside of small family factory, without using so much space, time and sources for workers.

What are the advantages of an oil press?

As the core equipment for converting oilseeds into edible oil, oil presses offer distinct advantages in efficiency, cost, quality, environmental friendliness, and flexibility. They are particularly well-suited for household use, small workshops, and commercial production settings.

- Physical pressing technology: Extracting oil directly from oilseeds via screw compression or hydraulic methods without chemical solvents, achieving high oil yields (e.g., peanut oil yields reach 40%-55%).

- Cold-Pressing Process: Low-temperature pressing (<60°C) preserves more natural nutrients (e.g., vitamin E, unsaturated fatty acids) while minimizing oil oxidation and harmful substance formation caused by high temperatures.

- Heat-Pressing Optimization: Applying heat treatment to high-oil-content raw materials (e.g., rapeseed, cottonseed) before pressing further enhances oil extraction rates.

- Save raw material costs: When producing for self-use or small-scale processing, locally sourced oilseeds (such as peanuts, sesame seeds, sunflower seeds) can be used directly, avoiding price fluctuations associated with purchasing finished oils.

- Reduce processing costs: Compared to large refineries, small oil presses eliminate the need for complex pretreatment steps (such as hulling or steaming/roasting), thereby lowering energy consumption and labor expenses.

- Byproduct utilization: Pressed meal residues (e.g., peanut meal, rapeseed meal) can serve as high-protein feed or fertilizer, enabling resource recycling.

A small-scale vegetable oil production line is a plant oil processing system suitable for daily processing of 1-20 tons, mainly composed of a pressing line (spiral oil press) and a refining line (refining machine). The pressing line is responsible for processing oil into crude oil, while the refining line further removes impurities and improves the quality of the oil.

Application case of small-scale vegetable oil production line

- African market: In many countries or regions in Africa, such as Tanzania, Nigeria, Uganda, etc., small-scale vegetable oil production lines have been widely used in the production of peanut oil, sunflower oil, palm oil, etc.

- Southeast Asian market: In countries such as Thailand, Malaysia, and Indonesia, small-scale vegetable oil production lines are used to produce palm oil, coconut oil, and more.

- Domestic market in China: In China, small-scale vegetable oil production lines are widely used in local oil workshops, family workshops, and small businesses, such as Henan and Hunan.

As an efficient, low-cost, and adaptable solution for vegetable oil processing, small-scale vegetable oil production lines are widely used worldwide. It not only provides good development opportunities for entrepreneurs and small businesses, but also contributes to local economic development and food safety. In the future, with the continuous advancement of technology and the sustained growth of market demand, small-scale vegetable oil production lines will play an important role in more fields.

It is best to obtain a good oil press in the first stage of processing, as this is the most important. No need to save costs on other machines and participate in the process. The machine quality of the vegetable oil production line is just like the quality of seeds, Zhengzhou Fude Machinery guarantees you the best quality of vegetable oil.

Related recommendations

-

Small oil pressing production line

368Our small oil pressing line consists of various equipments that work together to produce oil from oil rich seeds or nuts such as sunflower seeds, pea nut kernel, soy beans, cotton, sesame seeds and many others. When the individual machines are...

View details -

What is the purpose of an oil press

740Oil press is a type of oil processing machinery that extracts vegetable oil by squeezing pre treated oil. The spiral oil press used as a pre press machine is used to pre press the oil material under high pressure, and the pre pressed bad cake is ...

View details -

Soybean oil Extraction with Oil Pressing Machine

430Soybean oil is one of the major vegetable oils in the world, occupying a significant share in the global edible oil market, and the global production of soybean oil is usually more than tens of millions of tons. China, the United States, Brazil a...

View details -

De-waxing-An Important Process of Edible Oil Refining

576In the skin, shell and cell walls of vegetable olseeds, such as corn germ oi, sunlower oil, and rice bran oil.there is a certain amount of wax Inthe process of making oil, the wax will enter into the oi. Under the temperature of 30 centigrade, t...

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business