Small oil factory production line

Around the world, the consumption of edible oils is growing by the day. You have probably noticed that the demand for different types of oils is also increasing as people have differing tastes and uses of the same. What you may not know is that such oils are produced from a variety of simple seeds and nuts such as soya, coconut, maize, sunflower, ground nuts, macadamia seed, sesame seed and mustard seed to name a few. So, how is oilseed extracted and processed?

Table of Contents

- Preparations Before Starting an Oil Press Factory

- Small Oil Press Production Line Configuration List

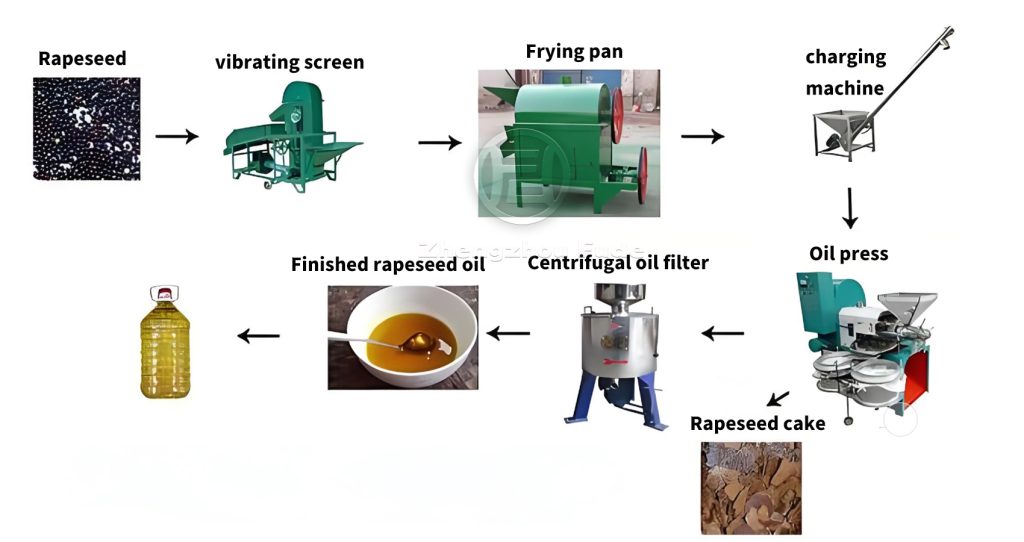

- Oil Extraction Equipment Production Process Flow

- What raw materials can an oil press process?

- Join the oil press business

Preparations Before Starting an Oil Press Factory

With the growing popularity of healthy eating concepts, demand in the edible oil market continues to rise, making the establishment of a food oil processing plant an attractive choice for many entrepreneurs. Among the equipment, the screw oil press has become the core machinery for small and medium-sized oil mills due to its high efficiency, energy savings, and user-friendly operation.

- Analyze local cooking oil consumption habits (such as preferences for rapeseed oil, nut oils, coconut oil, etc.) to determine the primary product types.

- Assess the stability of oilseed supply and establish long-term partnerships with farmers or suppliers.

- Adequate water and electricity: Ensure stable power supply (it is recommended to have a backup generator) and access to clean water sources.

- Convenient transportation: Proximity to raw material sources or transportation hubs reduces shipping costs.

- Factory Layout: Prepare raw material storage areas with moisture-proof and pest-proof features, equipped with ventilation systems.

- Pre-processing Workshop: Includes cleaning, crushing, steaming, and roasting processes. Equipped with oil presses and refining machinery.

Small Oil Press Production Line Configuration List

The small-scale oil extraction production line consists of a screening machine, oil press, roasting machine, oil filter, refining equipment, and packaging machine. Equipment is configured based on raw materials and production capacity.

- Pretreatment:The first in this step is cleaning. You will remove various impurities such as sand, leaves, stones, liquids and metals from the edible material using different machines such as a vibrating sieve, destoner, cyclone separator and metal remover. Proceed to soften the raw material in a crusher before hulling then flaking or rupturing it in more machines.

- Expelling:You will then expel the oil from the kernel by using a press. This can either be a cold press where you only use pressure or a hot press where you include heat and chemicals.

- Extraction:It is here that you extract the oil from the raw material using extraction machines. They remove the oil using mechanical pressure and further by chemical solvents.

- Refining:In this step you will refine the material further by using refining machines to remove unwanted pigments, flavours and chemicals. This makes the oil fit for human consumption.

- Filling:You are now ready to package your oil into bottles using filling machines which fill, label and seal your oil products.

| Product | Model | Hourly output (kg) | External Dimensions (mm) |

| Screw Oil Press | 125 | 300-400 | 2100*1400*1700 |

| Hydraulic Oil Press | 230 | Each load: 7–18 kg | 900*850*1550 |

| Oil Filter | 80 | 400 | 1600*650*1000 |

| Roasting Machine | 90 | 100 | 1750*1000*1150 |

Oil Extraction Equipment Production Process Flow

The screw oil press is a fully automatic hydraulic edible oil processing machine that uses a rotating screw shaft to continuously and efficiently extract oil from raw materials. Its core advantages lie in its compact structure, user-friendly operation, and high oil yield. Widely adopted by individual entrepreneurs, small-scale oil mills, and agricultural cooperatives, it supports the pressing of over 30 types of oilseeds, including peanuts, soybeans, rapeseed, and sunflower seeds.

- Employing a multi-stage progressive pressure increase principle, the chamber pressure rapidly escalates to achieve single-pass fission separation of oilseeds.

- Equipped with an infrared temperature control system, it automatically regulates pressing temperature (120-160°C) and moisture content to soften and activate oil molecules, enhancing oil yield while ensuring product quality.

- Supports both cold and hot pressing modes to accommodate varying oilseed characteristics.

- The vacuum filtration system rapidly separates oil residue, ensuring pure oil quality that meets sanitary inspection standards.

Hydraulic oil presses are designed based on Pascal’s principle (a principle of hydraulics). Within a sealed container, any change in pressure at a single point in a balanced fluid transmits to all directions with equal magnitude. By generating substantial pressure through the hydraulic system and applying it to the oilseeds, the oil within the seeds is squeezed out.

- High Oil Yield: Utilizing a multi-stage progressive pressure increase mechanism, the pressing chamber rapidly builds pressure to achieve complete oil separation in a single pass. Simultaneously, an infrared temperature control system automatically regulates pressing temperature and moisture content, directly softening the oilseeds to activate oil molecules. This ensures stable pressing and thorough extraction in one pass, significantly boosting oil yield. Compared to older equipment, normal oil yield can be 2 to 3 percentage points higher.

- Pure Oil Quality: Equipped with vacuum filtration and an automatic temperature control system, it removes residues from the oil, ensuring pure oil quality that meets health and quarantine standards.

Refining machines are critical equipment used to enhance material purity and remove impurities. They are widely applied in rubber recycling, oil processing, precious metal purification, textile and chemical fiber industries, as well as chocolate production. Their core function is to optimize material quality through physical or chemical methods, meeting diverse industry demands for high efficiency, energy savings, environmental protection, and intelligent operation.

What raw materials can an oil press process?

- Soybeans: Oil yield approximately 12%-18%. After pressing, the soybean meal can be used as feed or a protein source.

- Rapeseed (Canola): Oil yield 30%-45%, serving as the primary source of rapeseed oil.

- Peanuts: Oil yield 40%-50%. Peanut oil possesses a rich aroma and high market value.

- Cotton seeds: Oil yield 10%-20%. Requires detoxification treatment before pressing. Cotton seed oil is suitable for industrial or edible purposes.

- Sunflower seeds: Oil yield 25%-40%. Sunflower oil is rich in unsaturated fatty acids.

- Sesame: Oil yield 45%-55%. Sesame oil (sesame seed oil) has a distinctive flavor and is suitable for cold pressing.

- Flaxseed: Oil yield 30%-40%. Flaxseed oil is rich in alpha-linolenic acid, making it a healthy cooking oil.

- Perilla seed: Oil yield 35%-45%. Perilla seed oil possesses medicinal value.

- Safflower seed: Oil yield 20%-30%. Safflower seed oil is rich in vitamin E.

- Camellia seeds: Oil yield 20%-30%. Camellia oil is a premium edible oil with excellent storage stability.

- Walnut kernels: Oil yield 60%-70%. Walnut oil is nutrient-rich and suitable for infants and young children.

- Coconut meat: Oil yield 60%-70%. Coconut oil withstands high temperatures, making it ideal for cooking or industrial applications.

- Olive fruit: Oil yield 15%-25%. Olive oil is a core fat in the Mediterranean diet.

- Palm fruit: Oil yield 20%-30%. Palm oil is a high-yield vegetable oil.

Oil presses, with their high efficiency and versatility, can process a wide range of oilseeds and oil-bearing crops, serving applications across agriculture, food processing, and industrial sectors.

Join the oil press business

As consumers increasingly prioritize food safety and healthy eating, demand for natural, additive-free cooking oils has surged. Establishing a small-scale oil extraction production line enables tailored services—such as processing diverse oilseeds—for rural markets, community workshops, and health food stores, thereby avoiding direct competition with large enterprises.

By focusing on niche markets and leveraging technological optimization with value-added services, this approach achieves low-cost, highly flexible sustainable development.

Zhengzhou Fude Machinery, we are an integrated manufacturer and distributor, providing comprehensive solutions for clients nationwide. With extensive experience in oil extraction operations, we help clients develop business plans and expand their ventures. Join us today to unlock new opportunities in the oil extraction industry.

Related recommendations

-

How to buy screw oil press

363Selecting the perfect machine is crucial for your business success. We understand the challenges involved. Let's break down everything you need to know about screw oil presses, step by step. We want to empower you to make an informed decision. ...

View details -

How to Choose Sunflower Seed Oil Machines?

474Sunflower oil, refined through modern pressing or leaching processes, has become the preferred oil for home cooking and food processing because of its “low saturated fat and high vitamin E” characteristics. Choosing the right oil press machin...

View details -

What is a refining machine

655The edible oil refining machine is a small refining equipment used to refine crude oil, which can remove impurities in the edible oil, making the edible oil have a longer storage period, better color and odor, and greener and healthier. Main...

View details -

Oil mill owners: how to choose the right oilseed dryer

671Struggling with inconsistent oil yield or quality? Hidden drying problems might be silently eating your profits. Master oilseed drying to unlock better results and protect your bottom line. Yes, selecting the correct oilseed dryer is absolutely...

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business