Sunflower seed oil extraction

A sunflower seed oil press It extracts valuable oil from sunflower seeds. This machine is the engine of a profitable sunflower oil business. It takes a low-cost agricultural product and turns it into two high-value products: crude sunflower oil and protein-rich seed cake. We are Fude Machinery, a B2B manufacturer of oil processing equipment. We build the machines that help entrepreneurs like you create successful businesses. This guide will explain exactly what a sunflower oil press is, how it works, and why it is a smart investment for your business.

Table of Contents

- The process flow of sunflower seed oil extraction

- Process Characteristics of Oil Presses

- Oil Processing Auxiliary Equipment

- Advantages of small scale sunflower seed oil press machine

- Why Should Your Business Invest in a Sunflower Oil Press?

- What to Know Before You Buy a Sunflower Oil Press?

- Oil Processing: Comprehensive Recommendations

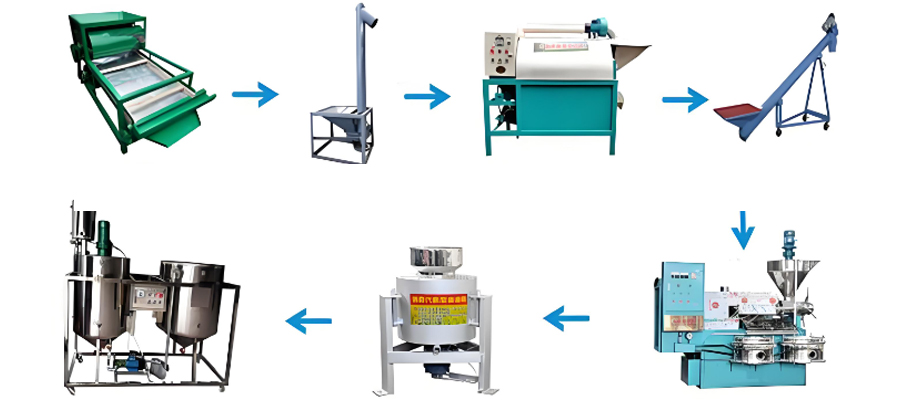

The process flow of sunflower seed oil extraction

- Raw material preparation: Choose sunflower seeds with high oil content, usually 30% -50%.

- Cleaning and shelling: Use a cleaning machine to remove impurities, and then separate the shell and kernel through a shelling machine.

- Crushing and steaming frying: Crush sunflower seeds and steam fry them to soften the oil and improve oil yield.

- Squeezing: It is carried out using a spiral oil press or a cold press, and is divided into two methods: cold pressing and hot pressing.

Cold pressing: retains more nutrients, suitable for high-end products.

Hot pressing: High oil yield, but slightly lower oil quality.

- Filtration and refining: The pressed crude oil needs to undergo coarse and fine filtration to remove impurities and residues.

- Degumming, deacidification, decolorization, deodorization: further refining through chemical or physical methods to ensure that the finished oil meets national standards.

- Packaging: Fill finished oil products into bottles or barrels for easy sales.

Process Characteristics of Oil Presses

The oil press machine is the heart of an oil pressing operation, but how it look or its structure will determine the ease of operation and the overall oil output rate. There are several types of these machines you will come across, however, we recommend two basic small scale sunflower seed oil press machines: one is conventional screw type, and the other is automatic press with vacuum filter.

Typically, the conventional screw small scale oil press machine is composed of a feeder, a gearbox, pressing cage, a screw shaft, and the extraction stand. All these are combined to realize continuous sunflower seed oil extraction with easier operations. The pressing chamber containing the pressing cage and the screw shaft is the key part of the functioning of this machine. the screw shaft on different modles is set up with various styles of screw, and they rotate when the machine is running to push the sunflower seed materials into the chamber. There the oil is separated out through extrusion of pressing worm as well as the pressing ring.

The Automatic oil press with vacuum filter is an advanced model of the conventional screw type, helping save labor power as well as simplifies the oil processing step. It’s composed of a feeder, a press chamber, the electric control, the heating system inside the press cage, the vacuum filter drum and an oils sight glass that help the user control the speed of oil clearing process. Both of these machines are pretty good when it comes to processing sunflower seed oil, but the conventional one is a little cheaper than the one with vacuum filter. However, the automatic oil press machine will yield better sunflower seed oil and can be set up very quickly.

Oil Processing Auxiliary Equipment

Small oil press: suitable for individuals or small businesses, equipped with spiral oil press, oil filter, refining equipment, etc., with low investment cost.

Large scale oil production plants: suitable for large-scale production, equipped with a complete set of pre-treatment, pressing, refining, and packaging equipment, such as the fully automatic production line provided by Fude Machinery.

Equipment advantages: Spiral oil press has a large output, low residual oil, and high production efficiency; The cold pressing process preserves more nutrients.

Advantages of small scale sunflower seed oil press machine

- Lower price and more acceptable: although the price of small sunflower seed making machine will vary from the functional configuration and the machines capacity, they are generally cheaper that large-scale oil press machine hence more acceptable to a majority of customers.

- Fewer requirements for operation: Both large and small oil pressing machines performs all the function necessary for edible oil production. However, small scale sunflower seed oil press machine are more convenient because they require fewer operation conditions like small space of operation.

- Less labor requirement: Most small scale oil pressing machines only requires 2 to 3 person to run the whole line.

- Functional: small-scale oils pressing machines for sunflower seed are capable of handling both hot and cold pressing, other than that, they can also be used to press other types of oil seeds.

If you have a small to medium-sized oil pressing workshop, then the small sunflower seed press produced by Zhengzhou Fude Machinery is your ideal oil pressing equipment. These machines have the characteristics of one-time pressing, low energy consumption, small footprint, and most importantly, require a small amount of investment.

Why Should Your Business Invest in a Sunflower Oil Press?

Investing in a sunflower seed oil press is a direct investment in profitability. Sunflower oil is one of the most widely consumed vegetable oils in the world. The demand is constant and growing. By processing the seeds yourself, you move up the value chain. You stop being just a seller of raw agricultural goods. You become a manufacturer of a valuable, in-demand product.

Create Two Revenue Streams from One Crop

This is the most important business advantage. A sunflower seed oil press does not just produce oil. It also produces sunflower seed cake. This cake is very rich in protein. It is a highly sought-after ingredient for animal feed. Many businesses find that the revenue from selling the cake can cover a large portion of their operating costs. This means you have two products to sell from a single raw material. This business model is very resilient and profitable.

The Factory-Direct Advantage

When you set up an oil production plant, the equipment is your biggest expense. By purchasing directly from a manufacturer like Fude Machinery, you eliminate the middleman. You do not pay extra commissions to traders or agents. You get a high-quality, reliable machine at the most competitive price. This lowers your startup costs significantly. It helps you become profitable much faster. We provide the equipment and the expertise to ensure your investment is a success.

What to Know Before You Buy a Sunflower Oil Press?

Making the right decision requires a little bit of planning. Before you purchase a machine, you should have clear answers to a few key questions. This will ensure that you buy the perfect sunflower oil press machine for your specific needs.

What Is Your Required Capacity?

The first question is about volume. How many tons of sunflower seeds do you plan to process per day? We offer machines with capacities ranging from 1 ton per day to over 10 tons per day. Be realistic about your raw material supply and your target market. Buying a machine that is too small will limit your growth. Buying a machine that is too large will be an unnecessary expense. We can help you calculate the ideal capacity for your business plan.

Will You Use Dehulled or Whole Seeds?

Sunflower seeds can be pressed with the black shell on, or after the shell has been removed (dehulled). Pressing dehulled seeds gives a lighter-colored oil and a higher-protein cake. However, it requires an extra machine for dehulling. Pressing seeds with the shell on is simpler. The choice depends on your target market’s preferences for the oil and the cake. Our machines can handle both types of seeds effectively.

Oil Processing: Comprehensive Recommendations

A sunflower seed oil press is a robust and profitable machine that forms the core of a successful oil business. It allows you to transform raw sunflower seeds into valuable oil and animal feed. By choosing the right type of press for your capacity and business goals, you can enter a stable and growing market.

Related recommendations

-

What equipment is used for refining

552Refinery equipment is a key device used to convert crude oil or other oil raw materials into various petroleum products or oil products. The refining process is complex and diverse, therefore requiring a wide variety of equipment. Here are some c...

View details -

What are the application areas of refining equipment

582The refining machines produced by Zhengzhou Fude Machinery are widely used in multiple fields, mainly for extracting and separating useful components in substances to improve their purity, quality, or value.

View details -

What is a refining machine? How can oil quality be improved?

189You have successfully used an oil press to extract crude oil. But what is the next step to grow your business? The answer is refining. So, what is an oil refinery machine? It is a set of equipment that cleans and purifies crude vegetable oil. Thi...

View details -

What is the application scope of hydraulic oil press

438Hydraulic oil press is a device specifically designed for extracting various vegetable oils

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business