The Future of Refining: Modern Technology Trends for Your Business

Is your oil processing operation ready for the future? Do you want to stay ahead in a rapidly changing industry? I am Fude Machinery. My company specializes in oil processing equipment. I see rapid shifts happening. Modern refining technology is evolving fast. It reshapes how we process edible oils. My goal is to equip your business with the latest innovations. This ensures you operate efficiently. You also meet high quality standards.

What Are the Trends in Sustainable Refining Technology?

Sustainability is no longer an option. It is a necessity. This drives significant trends in modern refining technology. These trends focus on reducing environmental impact. They also improve resource efficiency.

Responding to the global demand for sustainability, our oil processing equipment is engineered to align with green refining trends: cutting energy use, minimizing waste, and adopting eco-friendly chemicals. Advanced heat recovery systems capture waste heat to preheat raw materials, slashing energy costs and greenhouse gas emissions. Closed-loop water systems and efficient wastewater treatment reduce water consumption and effluent discharge, ensuring compliance with strict environmental regulations and demonstrating your commitment to responsible production.

How Can Energy Efficiency Be Improved in Refining?

Improving energy efficiency is a primary goal for sustainable modern refining technology. It directly translates into cost savings for your business. It also reduces your environmental footprint.

My multi-pronged energy efficiency solutions for oil refining include three core measures:

- High-performance heat exchangers recover heat from hot process streams (e.g., preheating cold crude oil with hot deodorized oil), cutting energy use by 20–30%.

- Optimized vacuum systems adopt advanced ejectors or energy-efficient liquid ring pumps to maintain deep vacuum for deodorization/ decolorization with lower steam and electricity consumption.

- Full insulation of heated vessels, pipes and exchangers plus precise temperature control minimize heat loss and avoid energy waste.These integrated measures reduce operational costs and enable greener, more profitable refining operations.

What About Waste Reduction and Byproduct Utilization?

Waste reduction and byproduct utilization are core to sustainable modern refining, turning waste into resources to boost operational profitability. Our oil processing equipment minimizes traditional refinery wastes (spent bleaching earth, soapstock, wastewater sludge): advanced filtration cuts oil retention in bleaching earth, reducing valuable oil loss and solid waste disposal. We also support byproduct reuse—spent bleaching earth can be reactivated or used as soil conditioner/brick material; soapstock can be processed for fatty acids (for soap/detergent production). Sophisticated wastewater treatment enables on-site water recycling, lowering freshwater demand and effluent discharge. These strategies reduce environmental impact, create new revenue streams, and enhance overall cost-effectiveness.

Are There New Green Refining Methods?

Emerging green refining technologies cut chemical use and environmental impact—our R&D team integrates these innovations into oil processing equipment for eco-friendly, high-efficiency production. Key trends include enzyme-based degumming (replaces phosphoric acid, uses mild conditions, reduces wastewater pollutants, boosts neutral oil yield), solvent-free/milder extraction (yields cleaner crude oil, lowering refining chemical and energy needs), and membrane technology (non-chemical separation alternatives). These solutions help produce high-quality edible oils with minimal ecological footprint.

Why Are Modular and Flexible Refining Designs Important for the Future?

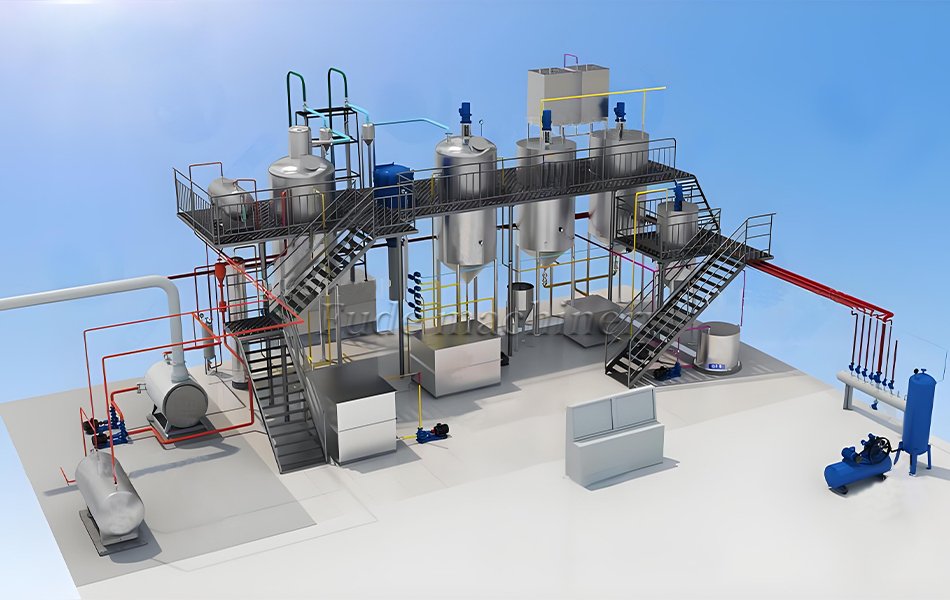

Modular, flexible designs are central to modern oil refining, delivering unmatched adaptability and scalability for dynamic market needs. Unlike traditional fixed large-scale plants with high upfront costs and limited flexibility, modular refining units are pre-built, transported, and assembled on-site—cutting construction time for faster production launch. They enable easy scalability (start small, add modules as demand grows) to lower initial investment and financial risk, plus flexible reconfiguration or relocation amid market changes. Our oil processing equipment adopts this modular concept, future-proofing your investment and providing a cost-effective, versatile solution for refining needs.

What are the Benefits of Modular Refining Units?

Modular refining units bring many benefits to your oil processing business. They optimize your investment and operational agility. They are a cornerstone of modern refining technology.

Modular oil refining units deliver core benefits: lower initial investment (start small, no need for large, costly plants—ideal for new entrants and market expansion), 30–50% faster deployment via off-site manufacturing (reduces on-site construction time and disruptions), easy scalability (add modules to boost capacity without full facility rebuild, minimizing downtime and maximizing ROI), and optimized space utilization (compact design fits limited land areas). A smarter, more adaptable refining investment.

How Can Flexible Designs Aid Diverse Raw Materials?

Flexible modern oil refining equipment is key to processing diverse raw materials—palm, sunflower, peanut oil, etc.—broadening market opportunities and boosting operational resilience. Unlike rigid plants limited to single feedstocks, our flexible designs cut reliance on one raw material source, shielding businesses from supply chain disruptions. They also enable rapid product changeover with minimal downtime, cleaning, and recalibration—ideal for specialized oils and blends. Engineered for quick parameter adjustments, our equipment helps you respond fast to market trends and stay competitive.

How Does Advanced Process Control Drive Refining Innovation?

Advanced process control is the core of modern oil refining—beyond basic automation, it leverages sophisticated algorithms and data analysis to ensure optimal performance and consistent product quality. Our equipment’s control systems use precision sensors and software to real-time monitor and adjust key variables (temperature, pressure, flow rates, chemical dosages). For example, they maintain exact deodorization conditions to remove impurities without damaging oil, boosting product quality and cutting energy use. Real-time data analytics also identifies trends and predicts issues for proactive optimization, keeping your refinery running at peak efficiency.

What Are the Global Market Trends Affecting Refining Technology?

Global market trends—rising demand for edible oils, stricter quality standards, and emerging market needs—shape modern oil refining technology. Population growth drives demand for higher-volume, efficient production of staple oils (palm, sunflower, soy). Consumers now seek oils with specific nutritional profiles and neutral tastes, pushing for more precise, pure refining processes. Tightening food safety and environmental regulations also require cleaner, safer operations, while developing markets need cost-effective, scalable solutions. Fude Machinery tracks these trends and adapts our oil processing equipment to meet evolving demands, helping you stay competitive in the dynamic global landscape.

Frequently Asked Questions

Question 1: What tech for future refining solutions?

Advanced automation (PLC/DCS), AI for maintenance and optimization, sustainable processes (heat recovery, waste reduction), modular designs, and real-time analytics for efficiency and quality.

Question 2: How does Fude Machinery stay competitive?

Through innovation, R&D on new materials/designs, adopting modern tech, prioritizing energy efficiency and sustainability. Factory direct sales and full support offer great value.

Question 3: Can SMBs gain from modern refining tech?

Yes. My modular solutions need low initial investment and allow flexible expansion. Energy savings and automation cut costs, helping SMBs compete and grow.

Question 4: What upgrade support does Fude Machinery offer?

Complete support: consultation, custom design, manufacturing, installation, training. After-sales provides tech help and spare parts for smooth operation.

Question 5: How do environmental rules affect your designs?

They drive designs focusing on energy efficiency to cut emissions, waste reduction, and byproduct use to minimize impact, meeting standards and boosting sustainability.

Summary and Recommendations

The future of refining is here. It is driven by modern refining technology. This includes automation, AI, and a strong focus on sustainability. I have shown you how these trends are transforming the industry. They offer new ways to achieve higher efficiency, better product quality, and reduced operational costs. My company, Fude Machinery, is at the forefront of these innovations. I design oil processing equipment that helps you embrace these changes.

I recommend you embrace these advancements. Evaluate your current refining processes. Consider how new technologies can improve your operations. Partner with a manufacturer like me, Fude Machinery. I offer cutting-edge solutions. I provide full-service support. This helps you upgrade your capabilities. This ensures your business remains competitive and profitable in the long term.

Are you ready to explore how modern refining technology can transform your business?

Contact Fude Machinery’s expert team today. Get a custom solution designed just for your business. Let us help you achieve your production goals.

Related recommendations

-

Introduction to multifunctional oil press

606Spiral oil press is a multifunctional equipment with the following characteristics: simple structure, small volume, easy maintenance, diverse oil pressing materials, high oil yield, large production capacity, and continuous processing. Sque...

View details -

Can the oil extracted from the oil press be consumed directly

572It is generally not recommended to drink the oil extracted from the oil press directly. If the quality of raw materials is reliable, the oil extraction process is hygienic, and it has been properly processed and stored, the extracted oil can be us...

View details -

What configurations are required for a tea seed sheller

442The tea seed shelling machine is suitable for various tea trees that can produce oil tea seeds suitable for shelling treatment

View details -

What Is the Purpose of an Oil Refinery Machine?

431The main purpose of an oil refinery machine is to purify crude oil. When oil is first extracted from seeds using an oil press, it is called crude oil. This crude oil is not ready for sale as a high-quality edible product. It contai...

View details

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business

Oil Press Equipment and Oil Refining Machinery for Sale – Start Your Oil Press Business